Mechanical Seal for Steam Turbines

Reduce process steam loss, improve turbine efficiency.

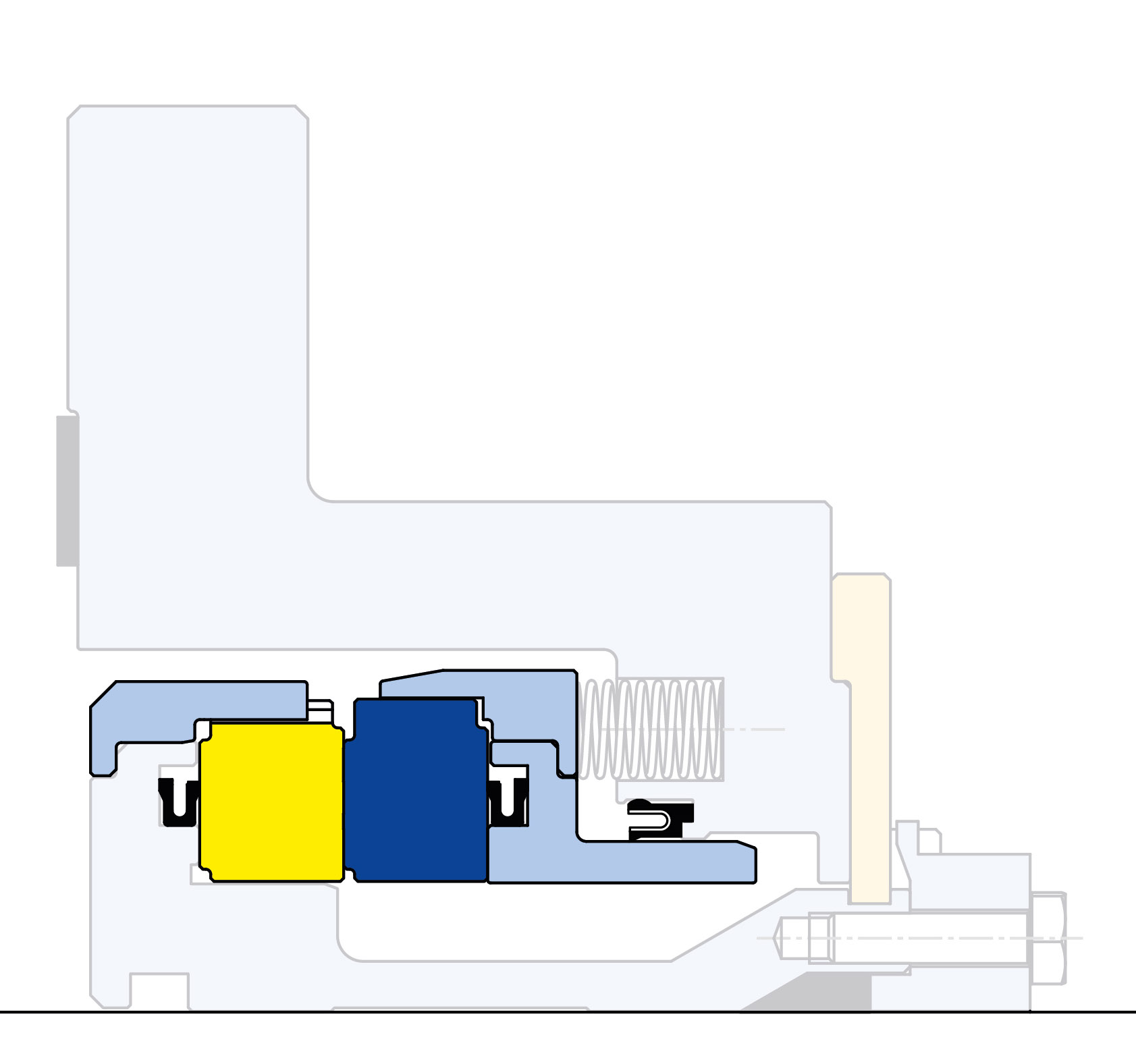

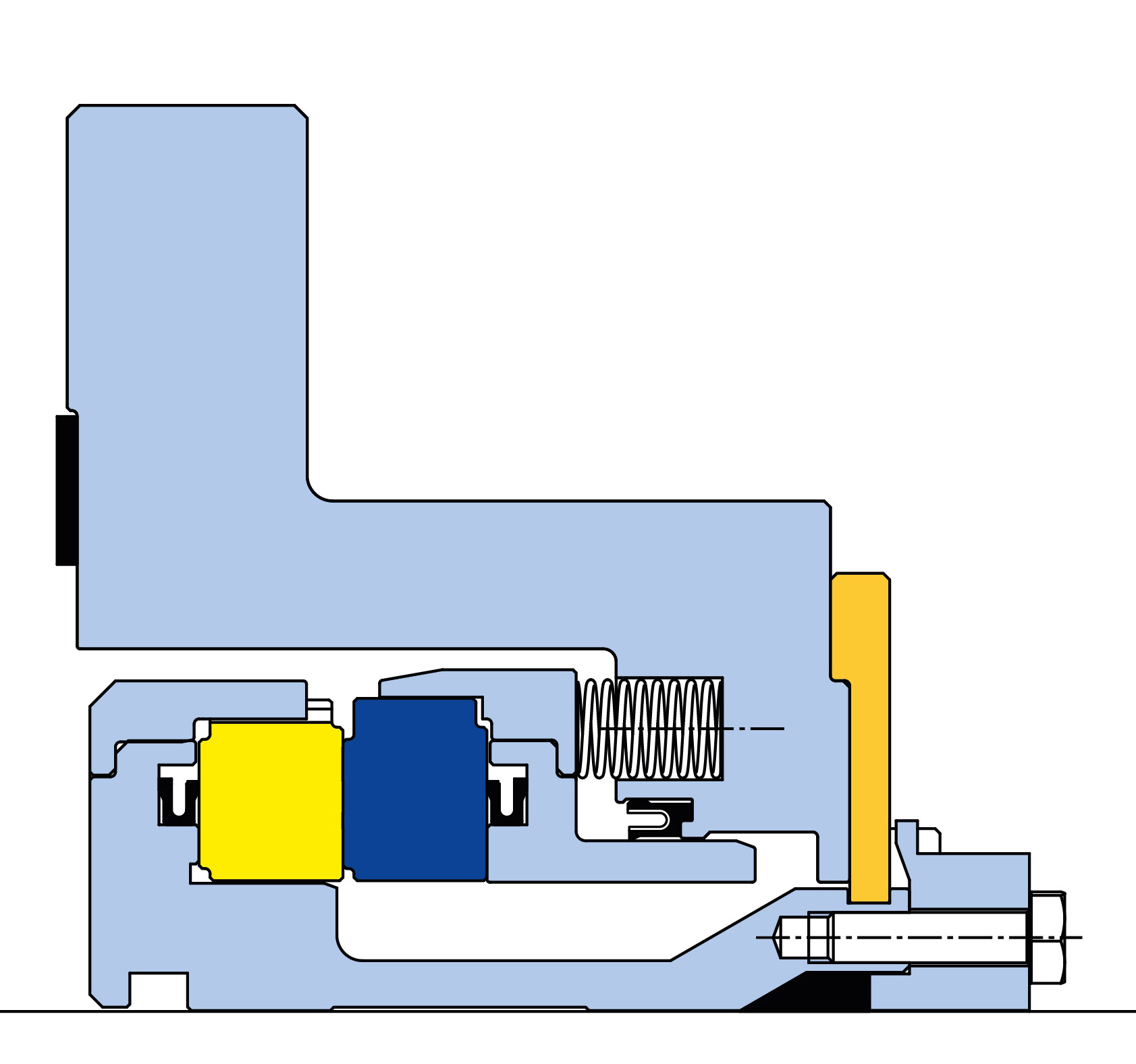

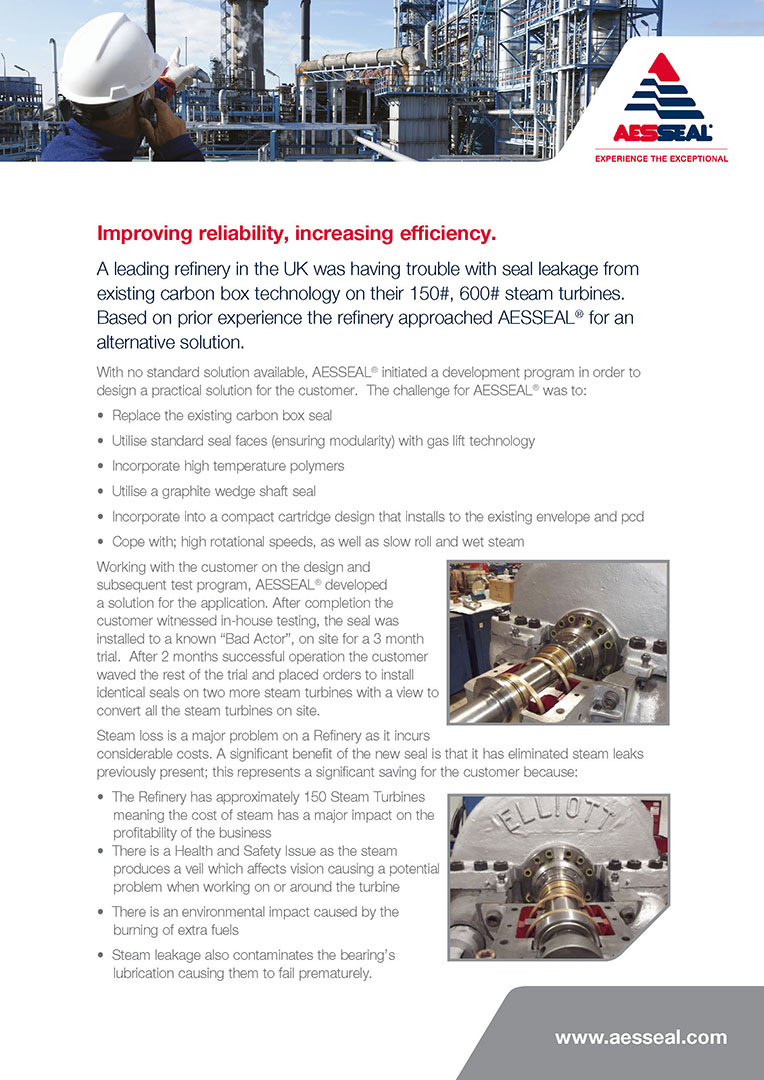

The STS™ mechanical seal has been developed in conjunction with a major oil refinery to replace existing carbon ring seals normally fitted to steam turbines. STS™ adopts AESSEAL® dry running gas compressor seal technology to provide a solution that significantly reduces the steam leakage typically associated with standard carbon ring seals.

Typical Benefits of Steam Turbine Mechanical Seal Technology

- Increased turbine reliability

- Reduced turbine maintenance costs

- Reduced bearing contamination

- Non-contacting technology extends life of seal

- Elimination of Shaft Wear – generated by the Carbon seal

- Greatly reduces steam loss and increases efficiency

Market-leading delivery performance from inventoried standard core modular components.

The adaptive hardware (sleeve and gland plates) can be rapidly CNC manufactured to suit specific machines.

Common equipment specific standard designs which are readily available are:

- TERRY 18ZS-1 (1.966")

- KKK BF4 (50mm)

S28 Hayward Tyler (2.500")

S28 Hayward Tyler (2.500")- TF12/RL12 COPPUS (1.503")

- 2AYR ELLIOT (2.250")

- 2BYR ELLIOT (2.932")

- 2DYR ELLIOT (2.932")

- RLH-24 COPPUS (3.003")