A US oil seed producer was finding that the single seals used in the production process were inadequate, and were failing on average every three to six months.

Case Studies

An oil seed producer in the US was reporting that in spite of trying a variety of possible solutions, single seals in the production process were only lasting a few months before failing.

Case Studies

AESSEAL stepped in when a mission critical general purpose steam turbine at a UK Ethylene production facility developed leaks and the original OEM seal housing was no longer available.

Case Studies

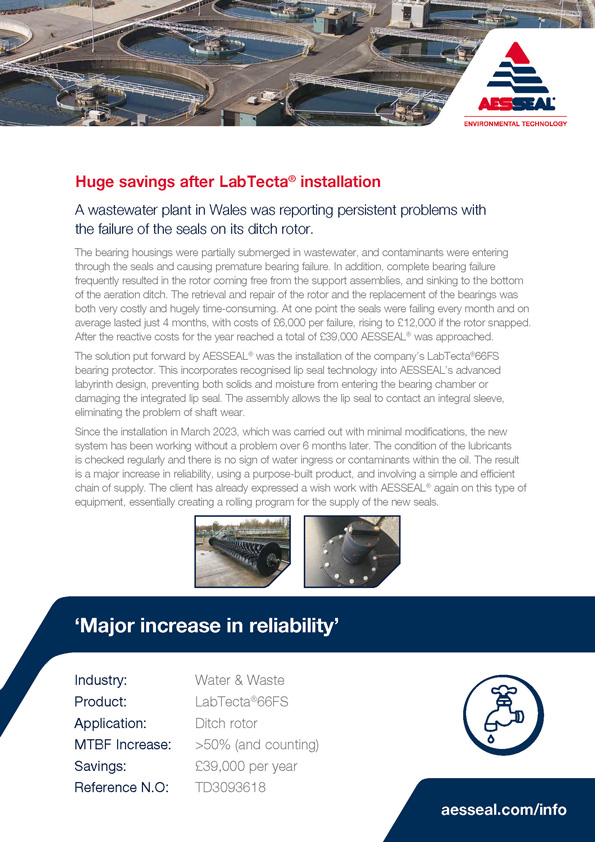

A wastewater plant in Wales was reporting persistent problems with the failure of the seals on its ditch rotor.

Case Studies

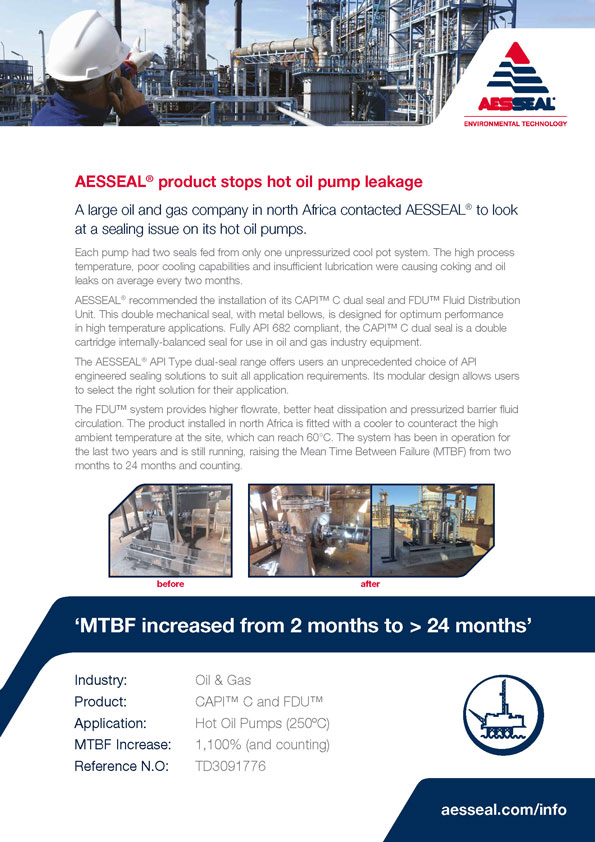

A large oil and gas company in north Africa contacted AESSEAL to look at a sealing issue on its hot oil pumps.

Case Studies

A leading UK company is set to save more than £5 million over five years following the installation of AESSEAL LabTecta OP bearing protectors.

Case Studies

A specialist in the application of solar power systems were looking for ways to improve reliability and turned to AESSEAL for help on a hot oil pump.