Description:

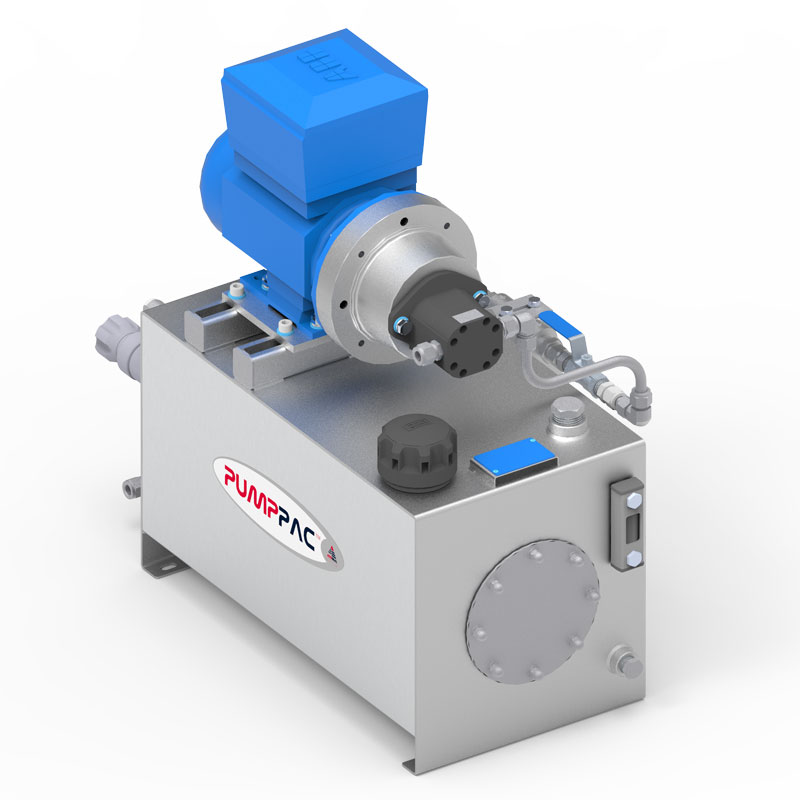

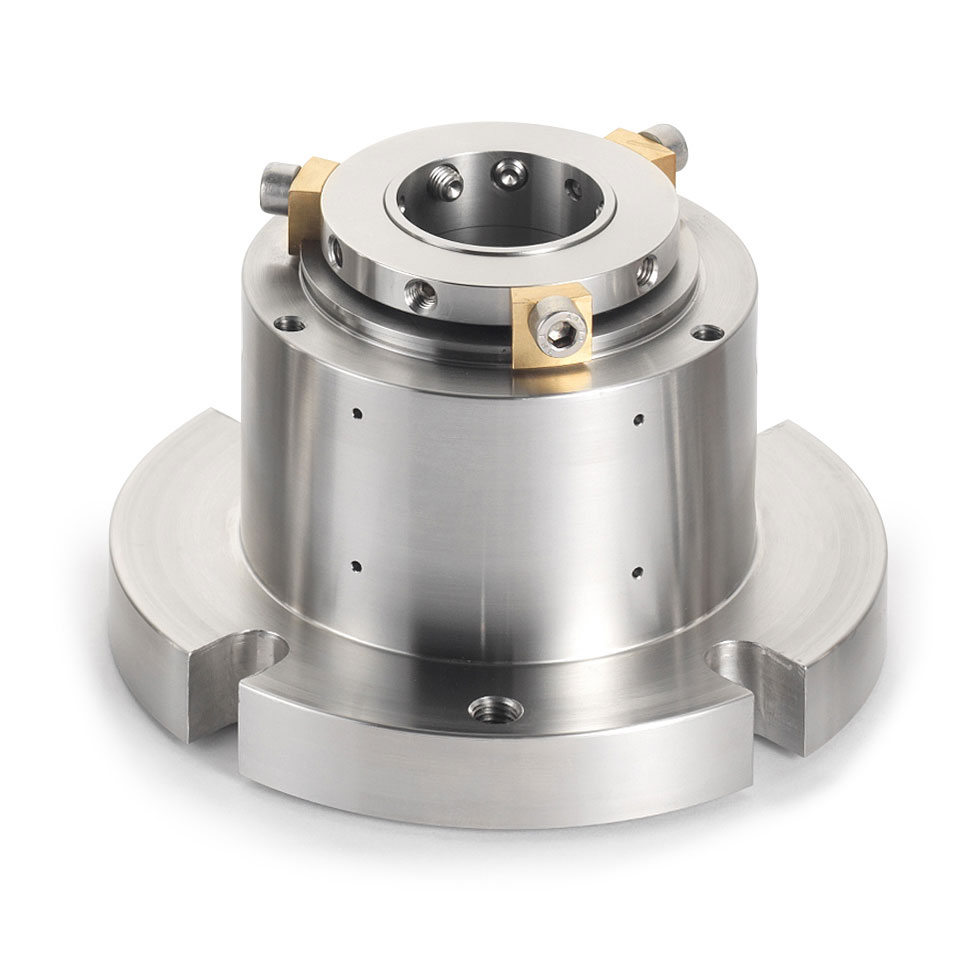

Pressurised external barrier fluid circulation from a central pressure source or by a stand alone pumping unit (e.g. AESSEAL® PUMPPAC™).

Features:

1. Ensures higher flow rate, better heat dissipation and positive circulation of barrier fluid.

2. If maintained properly, is the most reliable pressurised plan for dual seals as compared to Plan 53 A/B/C.

3. Can also be given as a stand alone unit per pump.

4. Increases cooler efficiency due to higher flow rate the heat exchanger.

Uses:

1. Applications where no leakage to atmosphere can be tolerated e.g. hazardous, toxic, inflammable.

2. For dirty, abrasives or polymerizing products where media is unsuitable as a lubricant for inboard seal faces.

3. For media with high pressure and / or high temperature and / or high heat generation between faces.

4. Wherever Plan 53 A/B/C circulation is insufficient to dissipate heat.

Caution:

1. Carefully consider the reliability of barrier fluid source, if a central source is used.

2. Expensive system, proper engineering required.

3. Circulating system must be pressurised at least 1.5 bar greater that the pressure in the seal chamber.

4. Product contamination does occur. Barrier fluid selected should be compatible with the process fluid.

5. Always check filter / strainer in the system for any possible blockages.

6. Loss of pressure in system can lead to entire barrier liquid contamination.

7. Product quality can deteriorate due to barrier fluid contamination.