Chemical & Pharmaceutical Case Studies

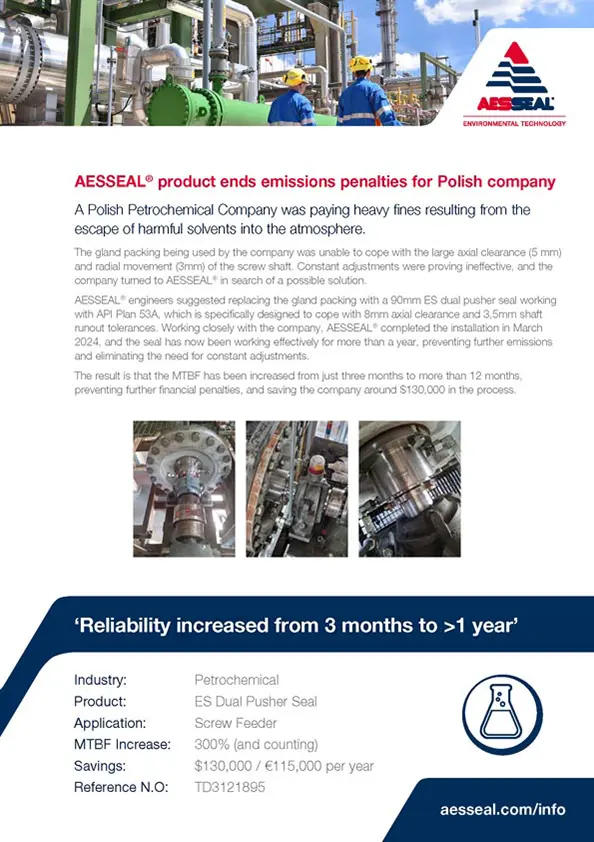

AESSEAL product ends emissions penalties for Polish company

Improved reliability with AESSEAL packing system

AESSEAL packing system brings major savings

A French pharmaceuticals company has saved over €200,000 in the first year following its decision to change to an AESSEAL reactor packing system.

LabTecta puts a stop to eight-year oil leaks

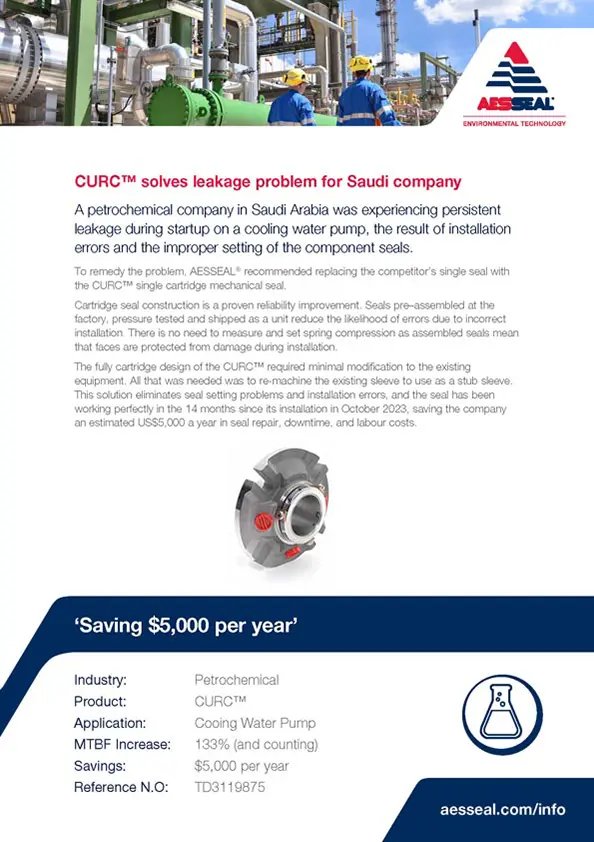

CURC solves leakage problem for Saudi company

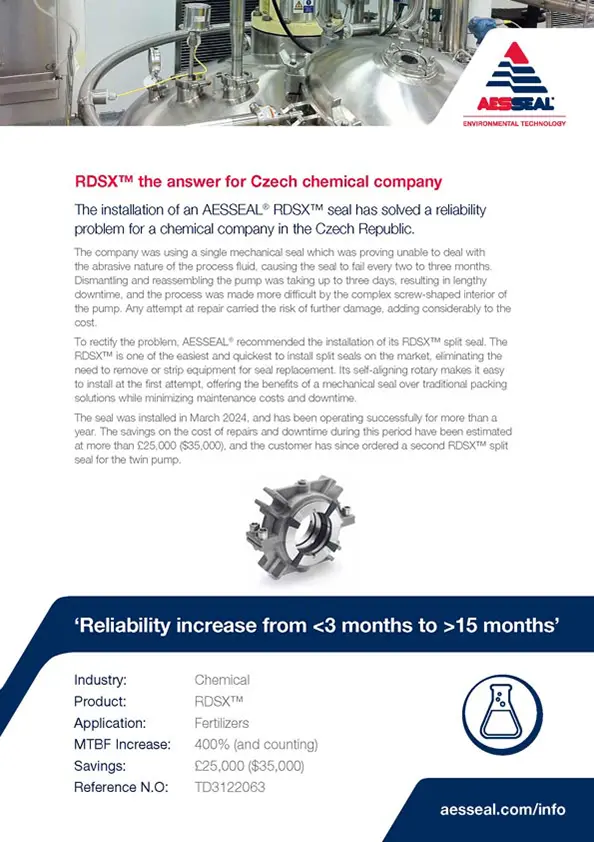

RDSX the answer for Czech chemical company

Dual seal cuts costs for UAE company

Rapid response saves the day for UK company

Upgrade will result in major savings for US company

Polish plant benefits from LabTecta protection

SA firm makes big savings with CDPN

Superior AESSEAL product and service seals the deal

Unique utilization of the cooling coil solves pump problems.

Reliability problem solved by AESSEAL CAPI Dual Seal

Huge reduction in water usage follows AESSEAL audit

Fast response the key in Polish contract

CAPI-TXS the answer for legacy quench oil pumps

FIDC cleans up at salt plant

LabTecta saves €360,000 for Spanish company each year

Dangerous oil leak problem solved by LabTecta FS

AESSEAL repair saves thousands for Saudi company

Major reliability improvement with CSSN seals

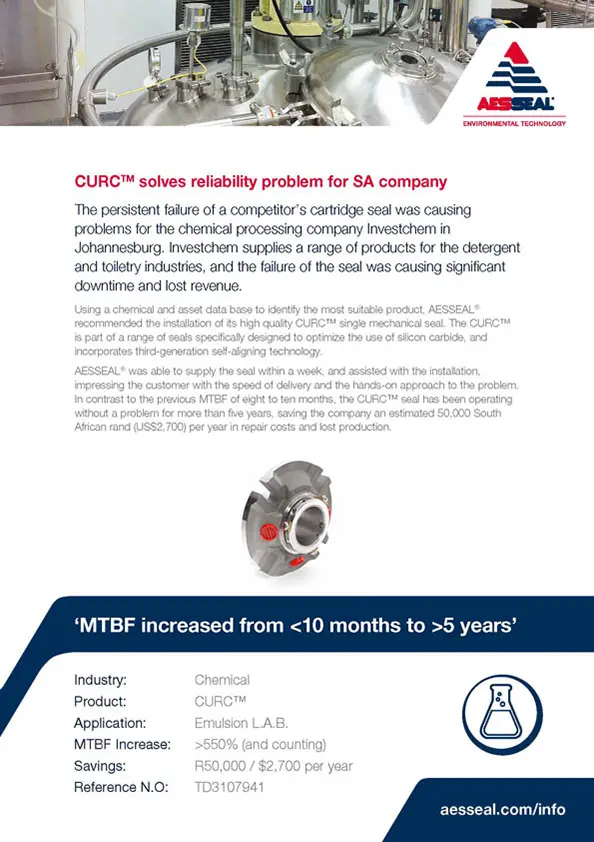

CURC solves reliability problem for SA company

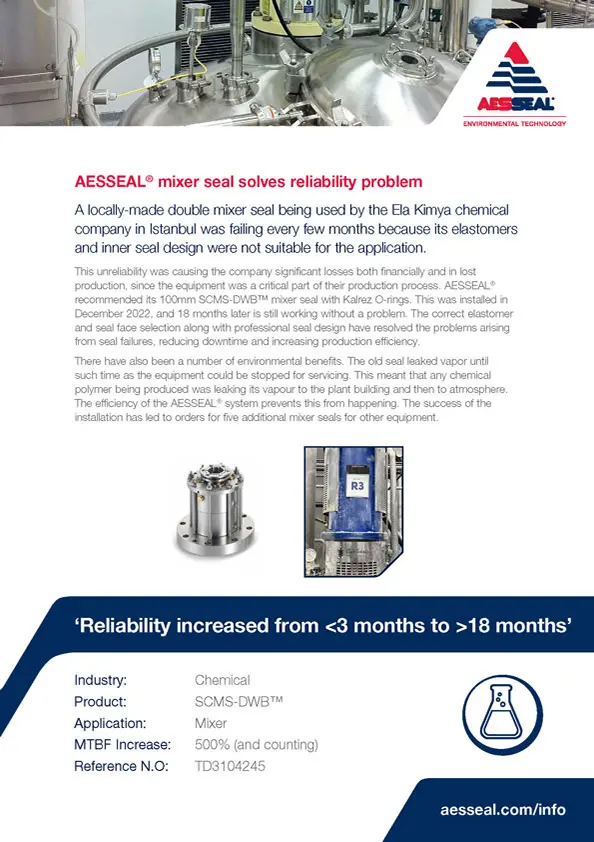

AESSEAL mixer seal solves reliability problem

A locally-made double mixer seal being used by the Ela Kimya chemical company in Istanbul was failing every few months because its elastomers and inner seal design were not suitable for the application.

DMSC is worth its salt

A poorly-designed seal was causing problems for a major salt producer in eastern France.

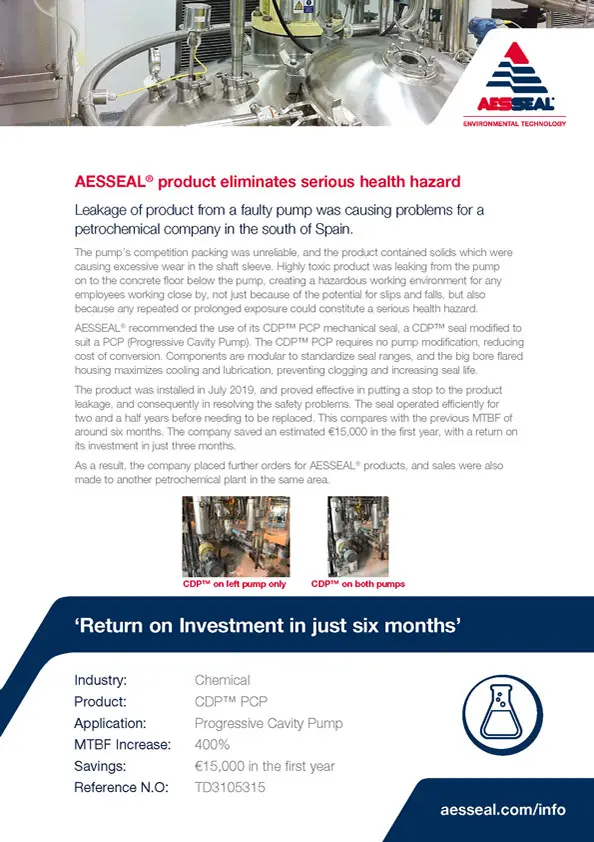

AESSEAL product eliminates serious health hazard

Leakage of product from a faulty pump was causing problems for a petrochemical company in the south of Spain.

AESSEAL improves reliability at French chemical plant

A chemical production company in France was experiencing premature failure of a competitor’s seal on a high temperature terpene process transfer pump.

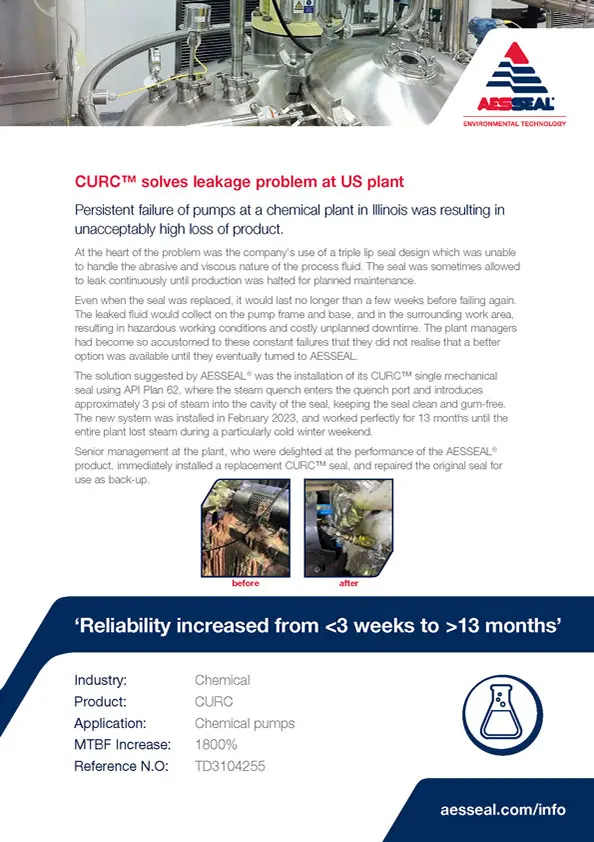

CURC solves leakage problem at US plant

Persistent failure of pumps at a chemical plant in Illinois was resulting in unacceptably high loss of product.

AESSEAL quality and service the key for Gulf company

A chemical company in the Gulf was looking to replace its existing pump single seal, which was continually leaking, and which they were having to replace about once a month. Typically, the replacement seal would begin to leak after just five to ten days.

Standard of service makes AESSEAL a clear winner

The seal on a pump at a chemical plant in the east of England was burning out on average every two weeks due to dry running, resulting in some four hours of downtime each time it failed.

Lower costs and greater reliability for US pharma company

LabTecta delivers reliability improvement

AESSEAL product solves seal failure problem

DMSF seals halt water leakage

Reduce maintenance costs with reliability upgrade

AES-Elast™ successfully replaces leading brand

Chemical plant saved over €500,000 in the first year

Efficient seal support system reduces energy costs

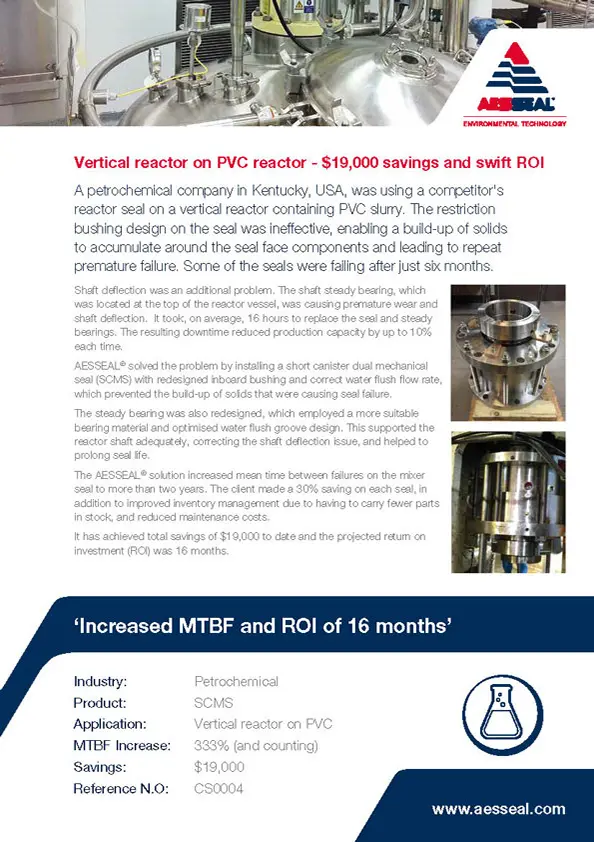

Vertical reactor on PVC reactor - $19,000 savings and swift ROI

Specialty Chemical Company achieves improved reliability

Cleaner plant with AESSEAL gland packing

LabTecta the answer for SA chemical company

Quality of service key to AESSEAL contract

Reduced maintenance after change to mechanical seal

Reliability upgrade improves Mean Time Between Failure by 5 times

Reliability upgrade improves Mean Time Between Failure from 1 week to 8 months.

A place of greater safety with AESSEAL SCMS

Reliability upgrade saves $24k per year

Increased reliability with AESSEAL bearing protection

Reliability upgrade improves MTBF 2900%

Gas seal gives 14 years trouble free operation

Reliable solution for high pressure, high temperature agitator application

Reduced downtime, improved safety

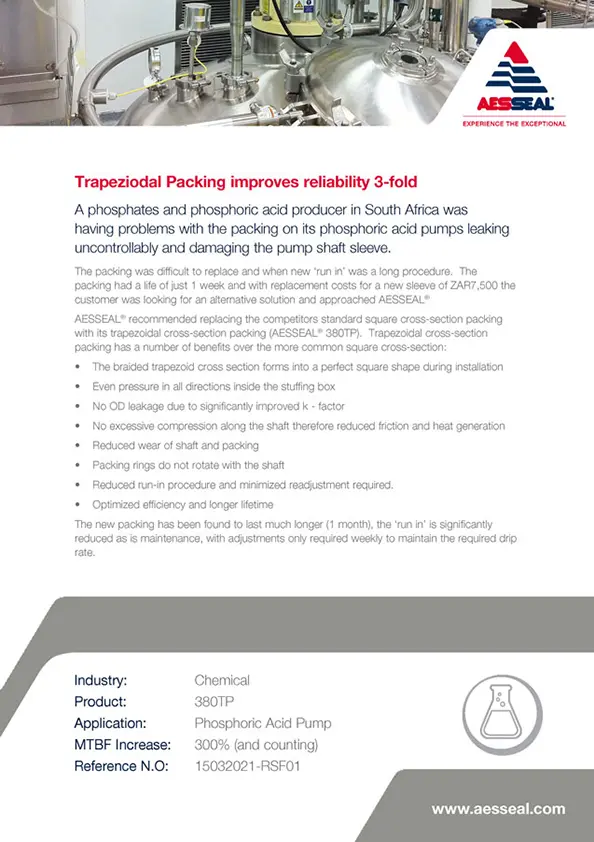

Trapeziodal Packing improves reliability 3-fold

Over 20 million litres of water saved in 5 years for just 2 pumps

Successful Support System Upgrade Improves Plant Reliability

Chemical company saves over $225,000 in first year

Reliability upgrade reduces seal repair costs

Chemical Producer Saves Over £1.7 Million in Plant Downtime

Upgrade delivers annual saving of 15,000 USD

Chemical company saves £9,400 and 17,000m3 of water a year

Chemical company saves a months worth of downtime

7 years trouble free bearing protection

Dry Gas Seal improves reliability and leads to a major overhaul program

Replacing lip seals with LabTecta66 improves gearbox reliability

Upgrading from packing reduces water usage and operating costs

Upgraded mixer seal delivers £28,000 in maintenance savings

AESSEAL upgrade solution improves MTBF and reduces costs

Saving water, the environment and our customers money

366% mean time between failure increase and over £5,000 per annum cost saving

Reduced pump failure delivered over $11,000 cost saving in first year of operation

540% increase in MTBF rates

$10,500 yearly cost saving for Chemical manufacturer