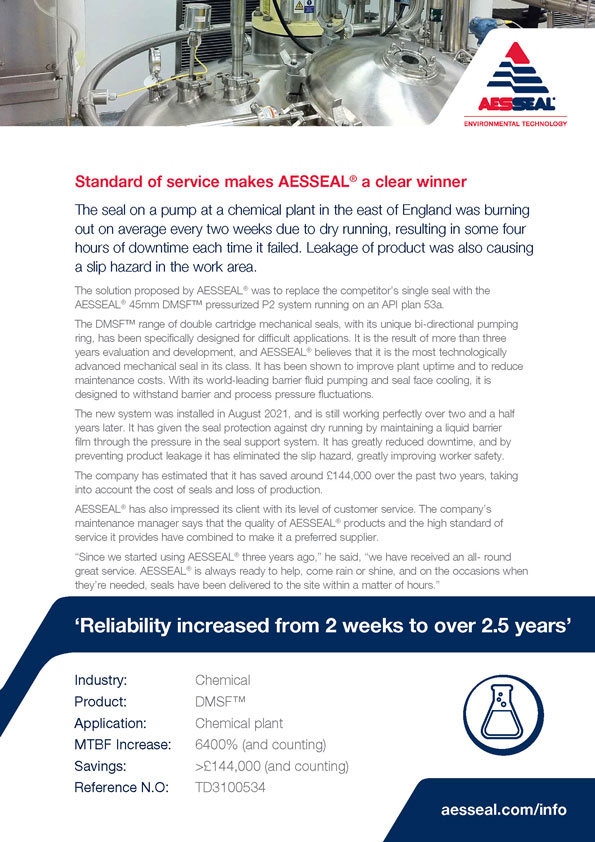

The seal on a pump at a chemical plant in the east of England was burning out on average every two weeks due to dry running, resulting in some four hours of downtime each time it failed.

Case Studies

AESSEAL were contacted by a power plant in the UK who were experiencing a major issue with their supply of mechanical seals.

Case Studies

A power plant in the UK were having frequent failures of the mechanical seal on a water circulating pump.

Case Studies

The installation of the AESSEAL EasyClean seal support system has led to major savings for a UK sugar company.

Case Studies

A pulp and paper mill in South Wales was having problems with contamination in its oscillator unit gearbox.

Case Studies

A global energy company was facing significant losses as a result of damage to the steam turbine housing at one of its ethylene plants.

Case Studies

AESSEAL stepped in when a mission critical general purpose steam turbine at a UK Ethylene production facility developed leaks and the original OEM seal housing was no longer available.