More Industry Related Content

With Mahesh Satrasala

AESSEAL® representative in the Middle East, Mahesh Satrasala, explains how a 12-week delay on the commissioning of a new oil and gas plant in Kuwait was avoided when AESSEAL® was able to step in to replace a competitor’s defective seal at short notice.

How did the contract come about?

This was a new customer who came to us after their OEM supplier told them that it would take around 12 weeks to replace a defective seal. The seal had failed during the commissioning process because the viscous nature of the product had clogged the springs and jammed the rotary face. When the supplier told them they would have to wait three months for a replacement they turned to us to see if we could help.

How did AESSEAL® convince the company that the CAPI™ seal was the right solution?

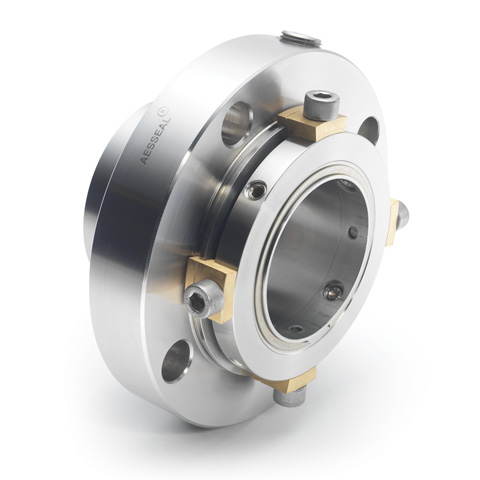

It wasn’t easy. This was the first time they had done business with us, and they were hesitant about changing to a new seal. However, we were able to convince them by explaining the reason for the failure, and then by demonstrating that the CAPI™ A stationary seal design was technically superior and more reliable, and would prevent the seal faces from jamming. We also pointed out that our modular technology and parts availability meant that we could supply a replacement within a few weeks, even though the gland (flange) had to be specially designed to meet the dimensions of their particular pump.

How was AESSEAL® able to supply the CAPI™ seal so quickly?

As soon as the order was received our team immediately drew up the necessary paperwork and raised a red ticket. At that stage the customer decided to revise the order and ask for a second seal. Our technical design team had the seal drawing ready for approval within a week, and even though it was mid-December and near to the Christmas holiday, we were able to deliver both seals by the end of the month, just four weeks after receiving the order.

Were there any other problems with the installation?

No. Even though the seal had to be specially designed, the installation process was very straightforward and was carried out without any difficulty.

Are the original seals still working effectively?

There are two pumps, and both pumps are running with our seals. They kept the competitor’s seals as spares but in fact they haven’t needed them because our seals are still working perfectly. The performance of the seals and our standard of customer service has led to significant additional business, including seal repairs, gland packing, and the supply of 56 LabTecta®OP bearing protectors.

What feedback have you received from the customer?

They were very impressed with the speed of our initial response and subsequently with the level of our after-sales service, which includes keeping in regular contact with the company to monitor the performance of our products. The seals are working exactly as we described and they have assured us that from now on AESSEAL® will be their preferred seal supplier.