AESSEAL is a specialist in the design and manufacture of mechanical seals and support systems.

Our Mechanical Seals are used in a wide range of pumps and rotating equipment worldwide to prevent liquids and gases escaping into the environment. We manufacture mechanical seal types to suit all industries and our investment in modular design means that we provide the best on-time delivery performance in the industry.

The AESSEAL® range of seals, seal support systems and bearing protectors are all designed to improve pump reliability and reduce maintenance costs. Our business is built around giving our customers such exceptional service that they need never consider alternative sources of supply.

AESSEAL® holds the world's most comprehensive standard inventory portfolio of mechanical seals, bearing protectors, seal support systems and packing. AESSEAL® operates from 235 locations in 104 countries, including 9 manufacturing and 44 repair locations, and has more than 300 customer service representatives who visit industrial plants every day. > Find Out More..

Featured Case Study

Reliability upgrade improves MTBF 2900%

A speciality chemical company was experiencing problems with the mechanical seal fitted on a phenol pump.

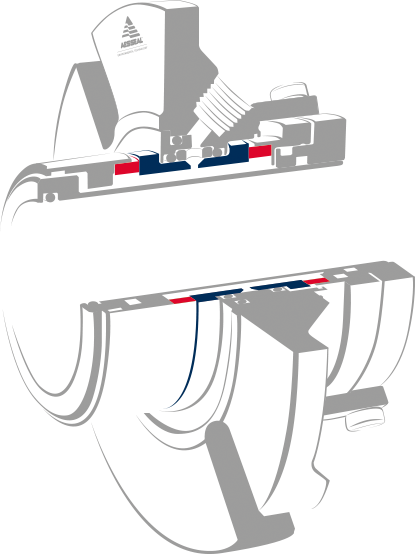

The single seal faces were regularly damaged by solids from the process fluid. The seal would subsequently leak heavily, causing harmful liquid to escape to the atmosphere, as well as causing a safety issue as the fumes reduced visibility. With the seal failing every 1 to 2 months the customer turned to AESSEAL for a solution.

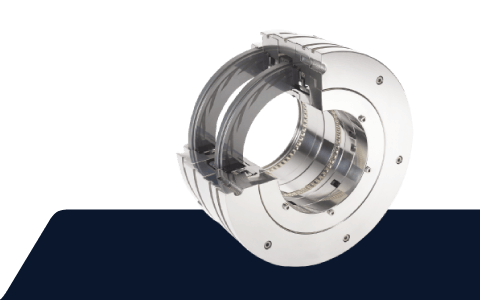

AESSEAL recommended replacing the seal with the dual seal (DMSF™) along with a SW water management system and fluid distribution unit to provide clean water at a constant pressure. This solution ensures the seal faces are provided with a clean cool barrier fluid, and by being pressurised ensures that solids from the process fluid cannot get between the seal faces. The new seal and system were installed in June 2014 on 10 pumps and has worked flawlessly for more than 5 years, which is a significant improvement over the previous solution.

The cost of upgrading the pump was returned in less than a year. The customer was so satisfied with the performance of the new system that it has now been fitted as standard on all their phenol pumps.

Our reputation for customer service and product performance is spreading quickly, and today we are working with an impressive portfolio of customers, in an equally impressive range of industries. Contact your local representative to see how we can help you.

How Much Could You Save?

For information on our privacy practices and commitment to protecting your privacy, check out our Privacy Policy.