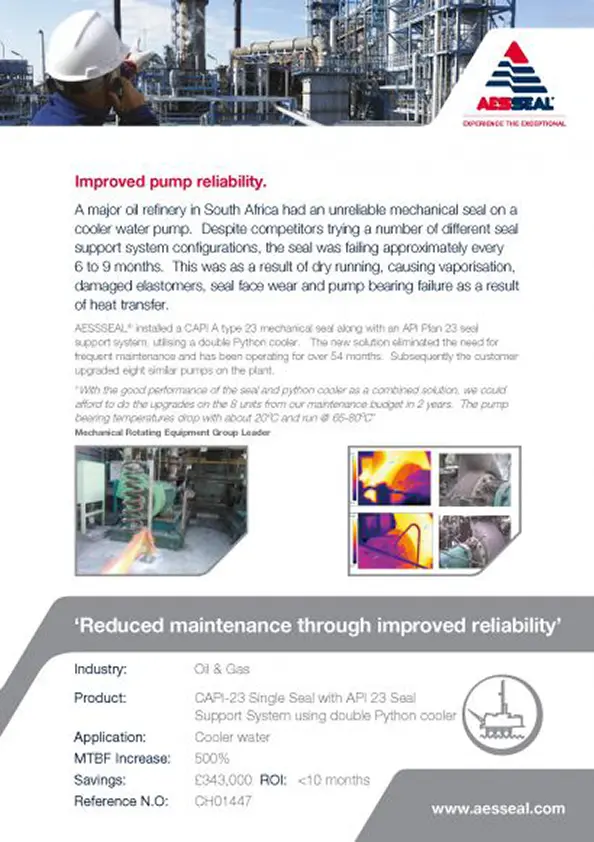

Description

Product recirculation from seal chamber to heat exchanger and back to seal chamber.

Features

- Circulation is maintained by pumping ring.

- In idle condition heat transfer is maintained by thermosyphon effect and in running condition by a pumping ring.

- Lower product stabilization temperature is achieved.

- Establishes required margin between fluid vapour pressure and seal chamber pressure.

Use

- In hot and clean services e.g. in boiler feed water and hot hydrocarbon services.

Caution

- Maintain maximum 0.5m horizontal distance from seal chamber to heat exchanger.

- Vent valve required at highest point of piping system.

- Ensure that pump has a close clearance throat bush.

- Ensure that the seal outlet connection is in the top half of the gland.

- Ensure that the cooler is mounted above the pump centre line.

- Vent the system fully before start up.