More Industry Related Content

With Kaleb Dyer

How did the contract come about?

The company has a contract with AESSEAL® for the supply of seals and systems. As part of the contract we carry out regular inspections of the equipment and report on its performance. In the course of these inspections we noticed that seals in the monomers area had grooved faces, so we stuck a borescope in the top of a pot and found that the internals were seriously degrading. Pieces of the degraded pot were flaking off and getting into the barrier fluid and damaging the seal faces.

What are seal pots, and what is their function in this application?

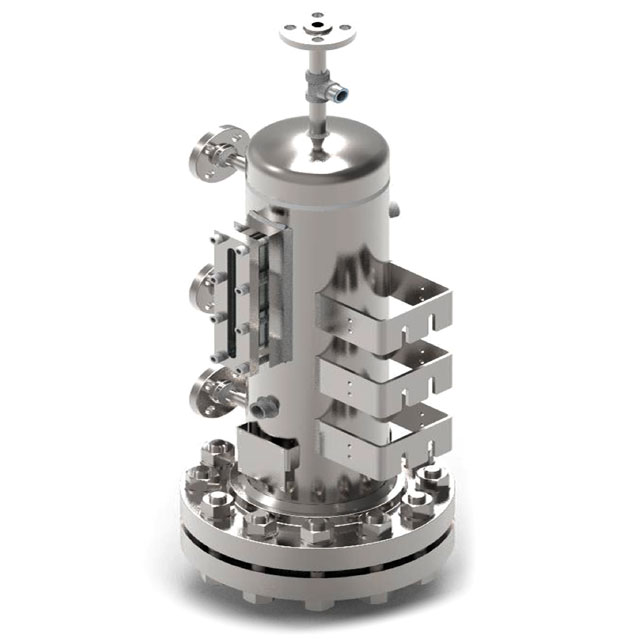

Seal pots house pressurized barrier fluid which provides lubrication to dual seal faces. The process fluid in petrochemical plants reaches a very high temperature. It also contains solids, so another fluid is required to lubricate the seal faces. In this case, contamination was being caused by a combination of seal pot/oil top-up header degradation and the abrasive action of solids from the process. The barrier fluid going to the seal would filter through these solids before reaching the seal faces, resulting in wear and premature seal failures.

Why were the pots degrading? Was it just their age?

Their age and the fact that they were carbon steel (no one makes a carbon steel pot anymore). They weren’t being replaced because once a seal pot is installed it generally won’t be removed unless it’s damaged or unless upgrades are needed. These pots weren’t damaged on the outside, and the rust and degradation on the inside was only evident once we carried out the inspection.

How did you convince the company that the AESSEAL system was the right solution?

It was a collaborative effort with their maintenance and operations team. The customer helped us design the port locations on the pot and they accepted our recommendation that the best option to solve the problem was the installation of our specially designed AES-12FV systems and stainless steel in-line filters. The new flanged seal pots, in conjunction with the in-line filters, help to provide cool, clean fluid to the seal.

How long did it take to get a decision?

We had been trying for years, but once we had shown them the extent of the degradation of the seal pot internals that was enough to get the ball rolling. Even so, it was a slow process, ultimately taking three years (between July 2020 and September 2023). A dedicated team could have done the job in a matter of a month or so, but we were only able to make progress when their pipefitters were free from other projects.

Can you describe briefly what it involved?

They started by replacing the oil header, reservoir, and pump. They would demo one seal pot and stand at a time and install a new pot, stand, and filter. It wasn’t a particularly complex process. The main problem, and the reason it took so long, was that the pipefitters were constantly being called away for other jobs.

What have been the benefits of the new system?

They now have a system which greatly reduces the risk that seals will fail as a result of contaminated barrier fluid. Before we began this process, they had between 25 and 30 seal failures in just three years. During the first half of this year they had four, and these were all bearing or pump-related and not outright seal failures. The AESSEAL system is saving them a lot of money, and it has opened the door for negotiations on possible contracts at other company sites.