Having the best possible protection for your bearings pump is vital, and when deciding between a lip seal or labyrinth seal there are many aspects to consider.

These include power consumption, shaft damage, pressure and speed constraints, maintenance time, fluid leakage and contamination rates, lifecycle cost and return on investment.

Here we compare and contrast to help you make up your mind.

What are your bearing isolation options?

A lip seal is a dynamic shaft seal designed to prevent leakage between a rotating shaft and stationary housing. It consists of a flexible sealing element made of elastomeric materials such as nitrate rubber or silicone, and has a lip-shaped profile that maintains constant contact with the rotating shaft surface.

A labyrinth seal is a non-contacting seal that uses a tortuous path to restrict leakage between rotating and stationary components. It does not rely on contact with the shaft surface, instead creating a series of chambers and restrictions that make it difficult for the sealed fluid to escape.

Is it Cost Related:

For most businesses this is the main consideration and, while the initial outlay for lip seals is less than for labyrinth seals due to their simpler construction, they do have a much shorter life and require more maintenance.

Why is this?

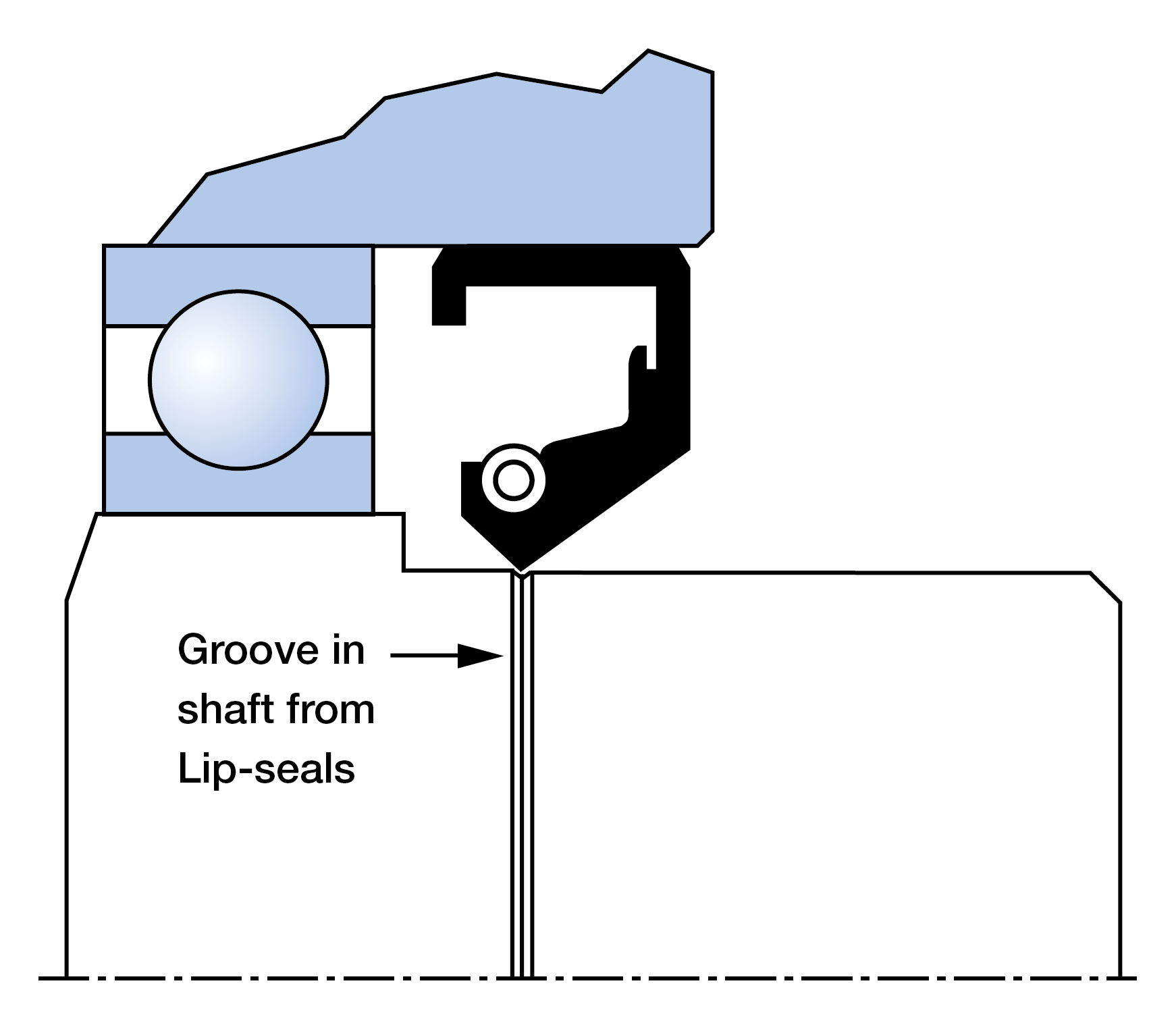

Shaft damage: Lip seals can only work through contact with the rotating shaft, which causes frictional wear, generates heat so uses more energy, damages the shafts and leads to extensive replacement costs.

Lip seals may last from a few thousand hours to tens of thousands (between 5,000 and 8,000 in moderate conditions), while labyrinth seals, due to being non-contactable, can often last the lifetime of the equipment (over 50,000 hours) as they do not wear and can even be fitted on a shaft previously damaged by a lip seal.

Shutdowns to replace a worn lip seal mean production is interrupted, equipment is shut down, and time and money spent replacing the bearings.

Fluid leakage and contamination:

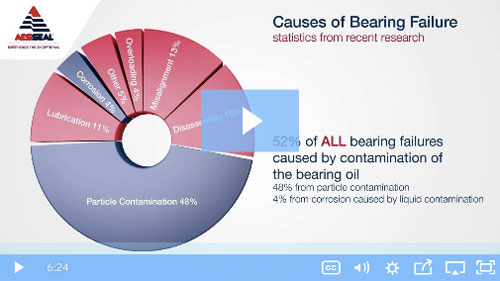

Lip seals require lubrication to reduce friction and wear at the sealing lip. They provide excellent exclusion of outside contaminants as long as the sealing lip remains intact, but seal leaking can allow ingress. Bearings fail because lubrication has been contaminated. Product and production are lost, and additional maintenance and parts costs incurred.

Labyrinth seals do not require lubrication and are highly resistant with their multiple teeth creating a tortuous path that effectively blocks contaminants. The LabTecta range of bearing protection is completely maintenance free and is IP66 rated, ensuring no leakage even when using a pressure washer in close proximity. Bearing seals prevent contaminants from reaching the inside of your parts while keeping lubricants from leaking out.

Power consumption:

Labyrinth seals use significantly less power than lip seals because they are non-contacting and produce virtually no friction. Lip seals, which rely on physical contact with the shaft to seal, generate considerable friction and heat, leading to substantial power loss. An average lip seal can consume around 147W of power, while a labyrinth seal uses virtually none.

To see how much you could save enter the amount of pumps you have on site in our calculator

Calculate SavingsPressure and speed ability:

High pressures can deform the flexible sealing lip, leading to immediate leakage or permanent failure. Problems worsen with insufficient lubrications, dirt caused by abrasive particles and excessive rotational speed. High speeds also intensify friction and heat, speeding up wear and compromising seal integrity.

High speeds can cause excessive heat generation and accelerated wear in lip seals. This is not the case with labyrinth seals.

Temperatures: Environmental limitations with temperature sensitivity can degrade the lip seal’s elastometric materials, resulting in seal hardening, cracking or losing its sealing force.

They are limited to temperatures below 250F (120C) while labyrinths can operate at much higher temperatures – typically almost twice as high.

Featured Case Study

A soda ash mine in the USA was using lip seals on a vertical turbine pump in the top discharge bowl to seal the oil lube on the pump line shaft. The pumps received infrequent maintenance and the lip seals were failing every three-four weeks causing a loss of bearing lubrication, two to three pump shaft failures a year and bearing oil was contaminating the nearby river.

The original lip seals with MO10 and SO70 component seals with tungsten carbide seal faces which eliminated leakage form the oil reservoir and improved the reliability of the pump. The plant then installed an identical system on another pump and estimate a $50,000 saving per pump per year – and no leakage into the river.

As a result of the success the plant has installed an identical system on another pump, and estimate that the upgrade has saved $50,000 per pump per year, whilst eliminating oil leakage into the river.

Read the full Study