Case Ref

TD3132883

Country

United Kingdom

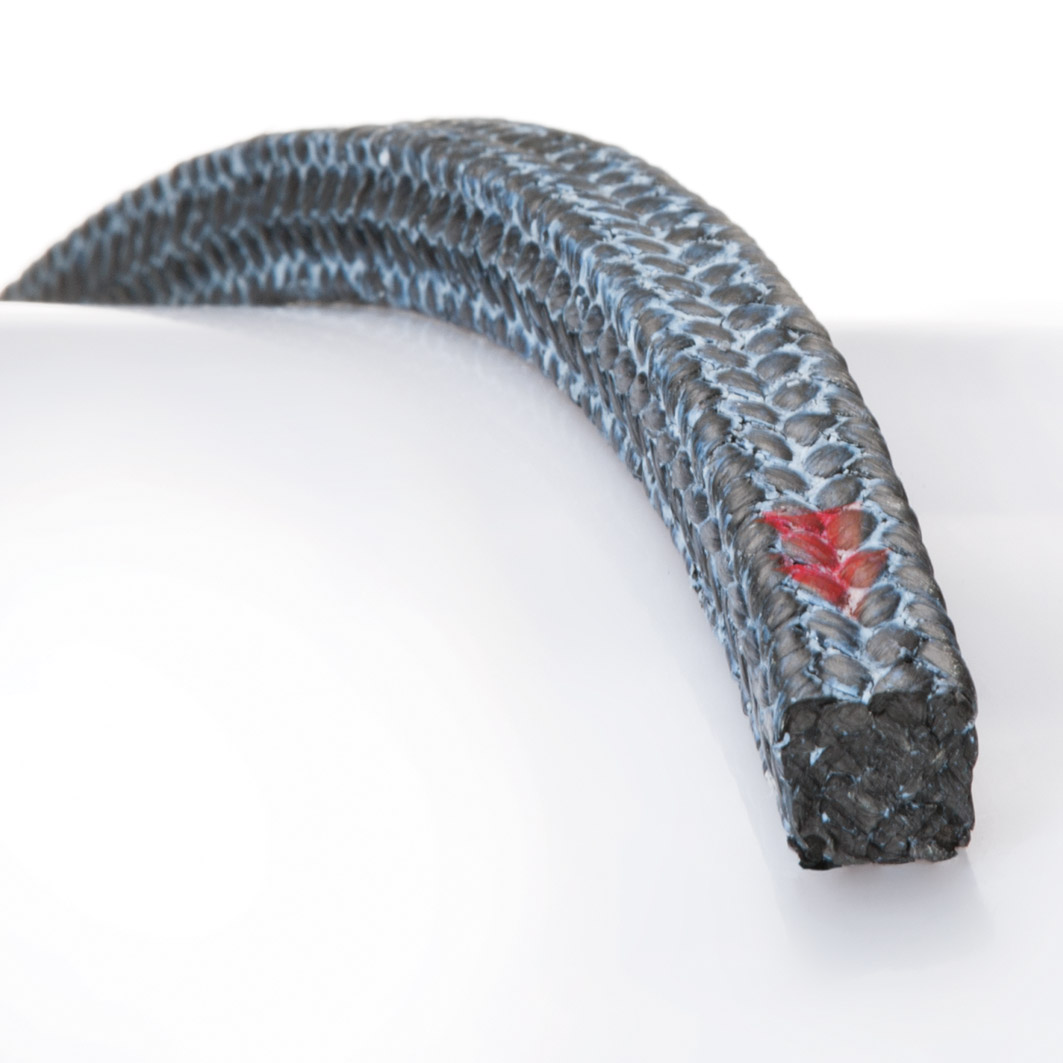

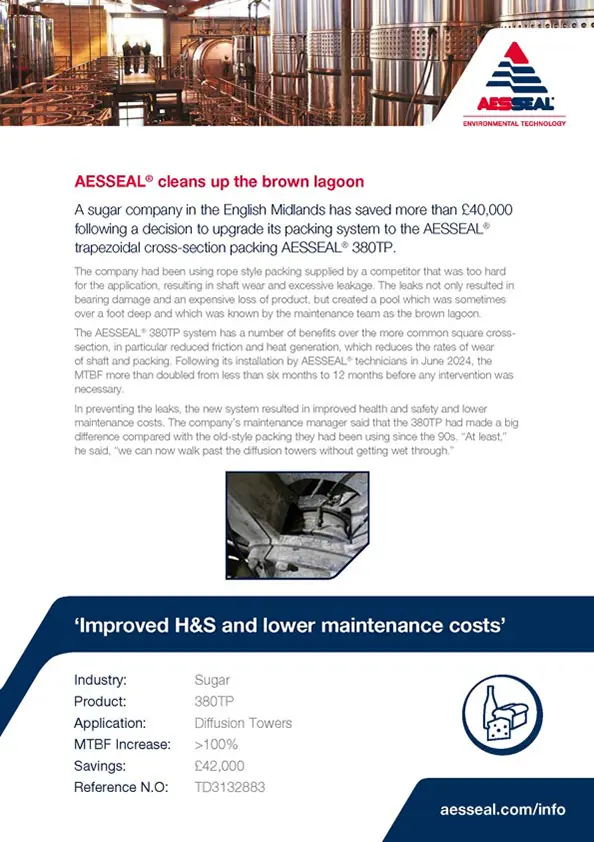

A sugar company in the English Midlands has saved more than £40,000 following a decision to upgrade its packing system to the AESSEAL® trapezoidal cross-section packing AESSEAL® 380TP.

More Industry Related Content