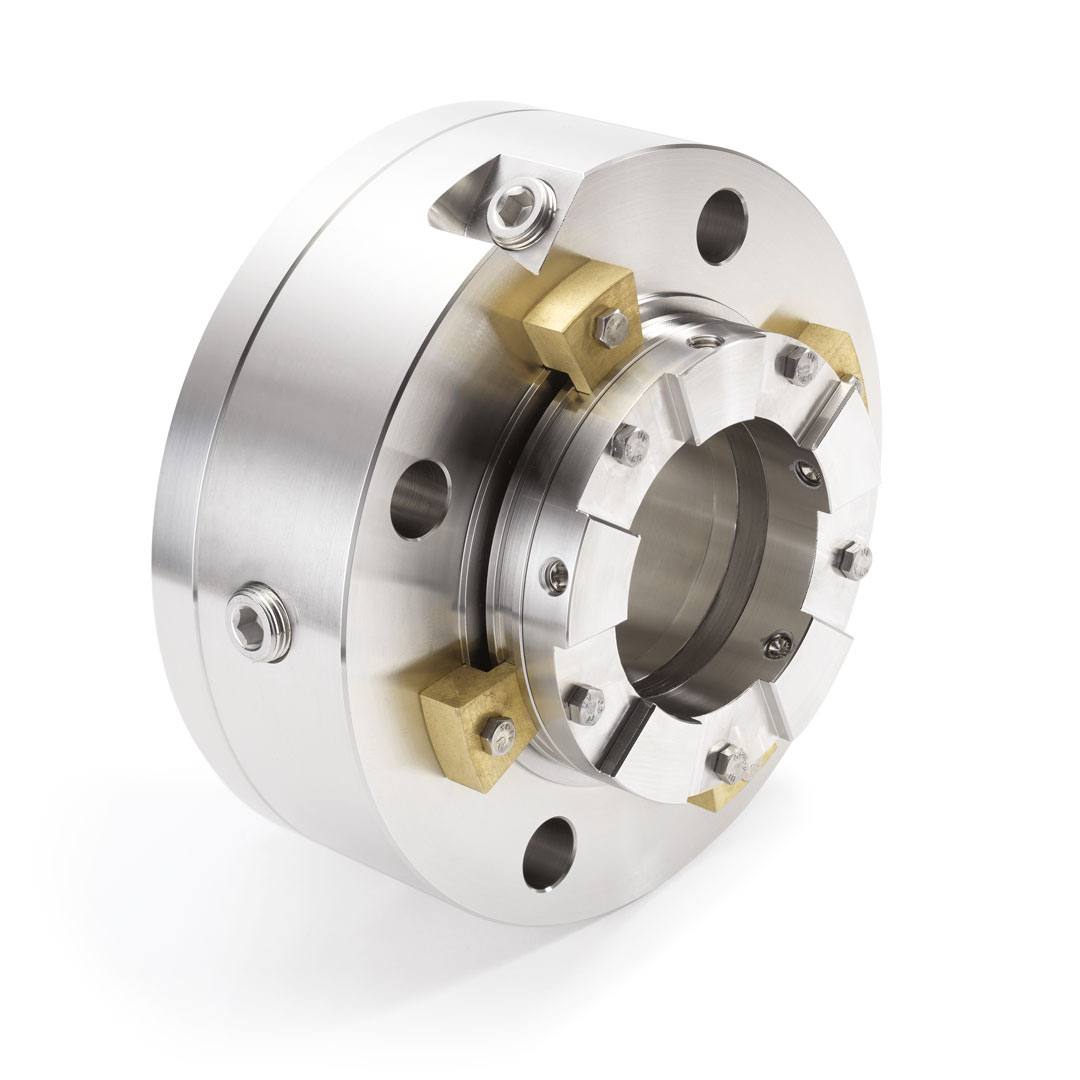

A containment seal is a secondary seal designed to capture normal leakage from a primary seal and to prevent the leakage of process fluid in the event of a primary seal failure.

The American Petroleum Industry (API) Standard 682 4th Edition defines a Containment Seal as;

A version of an outer seal used in Arrangement 2 and that normally operates in a vapor (gas buffer or no buffer) but will seal the process fluid for a limited time in the event of an inner seal failure.

Containment Seal History

Containment seals were brought to market in 1923 and evolved hugely prior to the emergence of tandem or dual seals.

Contrary to belief, all mechanical seals leak to some extent so accurate piping plans and awareness of the risks associated with improper practices are vital to ensure maximum safety and reliability in leakage management.

The different designs

Various designs have their own problems and dangers, so the correct seal must be selected and properly installed.

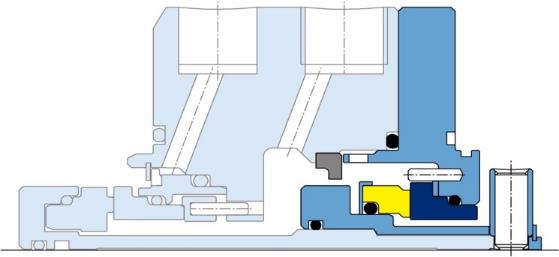

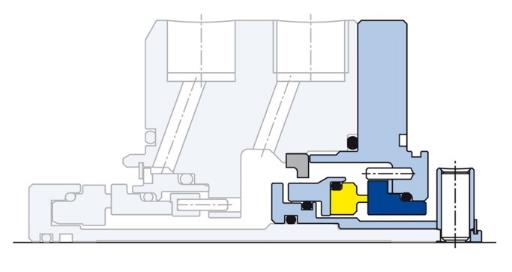

Why, when all seals should supposedly operate continuously for 25,000 running hours, aren’t they all the same? Contacting containment seals utilize self-lubricating carbon while non-contacting containment seals aim to eliminate wear and heat generation. However, the latter can experience significant leakage, with rates much higher than their contacting counterparts, which can have severe implications on emissions.

Containment Seal History

Containment seals were brought to market in 1923 and evolved hugely prior to the emergence of tandem or dual seals.

Contrary to belief, all mechanical seals leak to some extent so accurate piping plans and awareness of the risks associated with improper practices are vital to ensure maximum safety and reliability in leakage management.

The different designs

Various designs have their own problems and dangers, so the correct seal must be selected and properly installed.

Why, when all seals should supposedly operate continuously for 25,000 running hours, aren’t they all the same?

Contacting containment seals utilize self-lubricating carbon while non-contacting containment seals aim to eliminate wear and heat generation. However, the latter can experience significant leakage, with rates much higher than their contacting counterparts, which can have severe implications on emissions.

Perceptions within the industry

The industry perceives containment seals as dual seals. While many believe they offer the same reliability as traditional dual pressurized seals, data shows a higher failure rate for containment seals. Constant monitoring of these seals must take place, as operators may not be aware of failures until it’s too late.

Operational bad practice

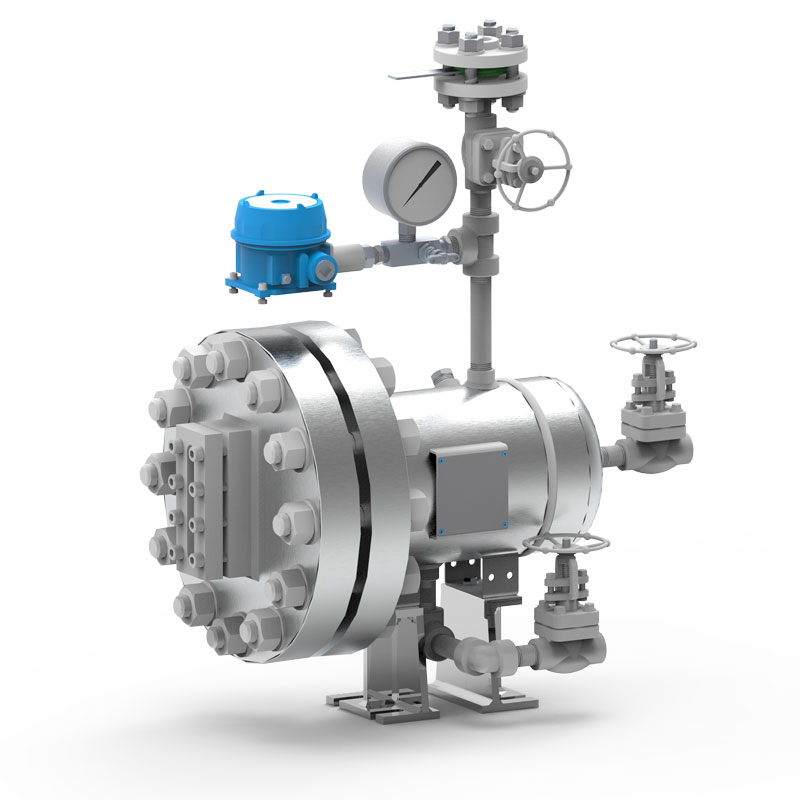

There are various misconceptions surrounding containment seals and their design flaws. The seals, which predate API Standard 682, often lack proper drainage and gas buffer provisions, leading to flooding and increased leakage rates. Seals must be connected to a flare and a drain, as failures in these systems can result in significant emissions. API Plan 76 systems are needed for installations to ensure effective monitoring and operation.

Safety considerations

There are safety concerns surrounding containment seals, which are often misapplied and unsupported. Inboard seals often exceed recommended running hours, and there is a lack of industry guidelines for integrity testing. Significant failure rates have been reported, prompting some operators to replace containment seals with dual pressurized seals. Proper monitoring and testing will help prevent catastrophic failures and better practices will enable many incidents to be avoided. Knowledge of operational safety risks associated with fluid containment is vital.

Total life costs

The popularity of containment seals is driven by their low purchase cost, although installation and ongoing costs are often overlooked. The practicality of utilities and the level of instrumentation are also frequently ignored factors. The belief that a plan fifty-three b is the most expensive solution for a standard fifty millimeters dual seal upgrade from a single seal is a misconception. Periodic testing for the integrity of containment seals is a must.

Safety risk assessments

A risk assessment paper from AESSEAL is available to help improve plant safety and reliability. There are safety risk assessments related to containment seals so it is important that seal conditions are monitored during operation. Current regulations are limited and there is a need for better testing and compliance measures.

For further guidance on containment seals please see our Whitepapers