Description

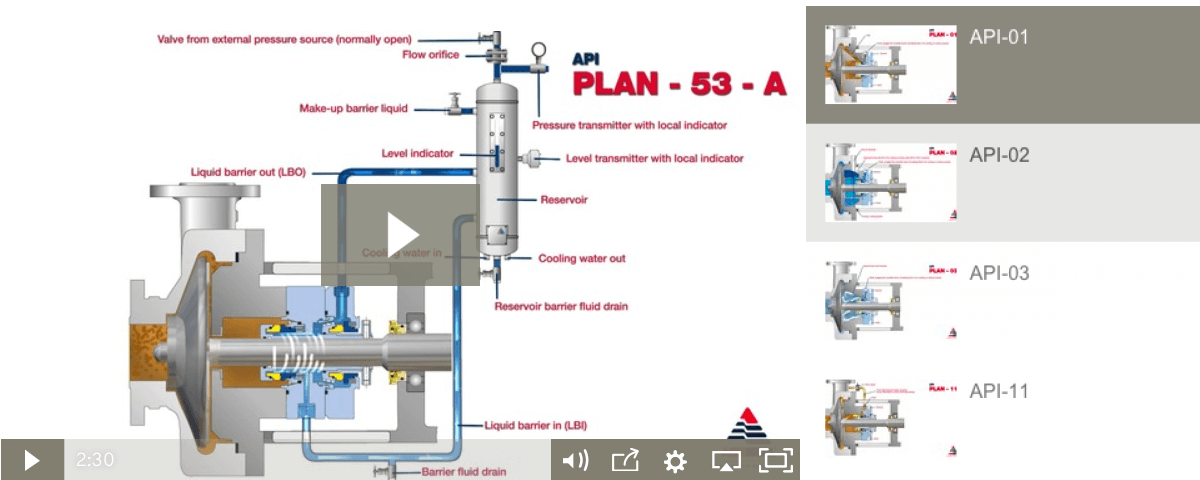

Leakage of condensate from inboard seal of a dual containment seal is directed to a liquid collector.

Features

- Can be used with Plan 72 with buffer gas or with Plan 71 without buffer gas systems.

- Collection can be redirected to process fluid by using separate pumping device.

- Can be used in single containment seal also.

- Test connection is provided to check the inner seal by closing the block isolation valve while pump is in operation and noting the time / pressure build-up relationship in the collector.

Use

- Duties with condensing leakages.

- Hazardous, toxic fluids.

- May also be used for non-condensing leakages. In such cases, the collector can help in collecting condensate from the vapour recovery system.

Caution

- Ensure that collection system is located below the seal drain with sloping pipelines.

- Drain port should be at bottom of containment seal to allow the leakage to flow to the collection system.

- Collection system should always be vented releasing vapors of process liquid to vapour recovery system.

- Valves that are installed should be accessible to operator relative to ground clearance and other obstructions.

- A flow control orifice is required to create back pressure on collection system and to have effective condensation of vapors.

- Pressure switch should be set at a gauge pressure of 0.7 bar.