Case Ref

TD3132885

Country

United Kingdom

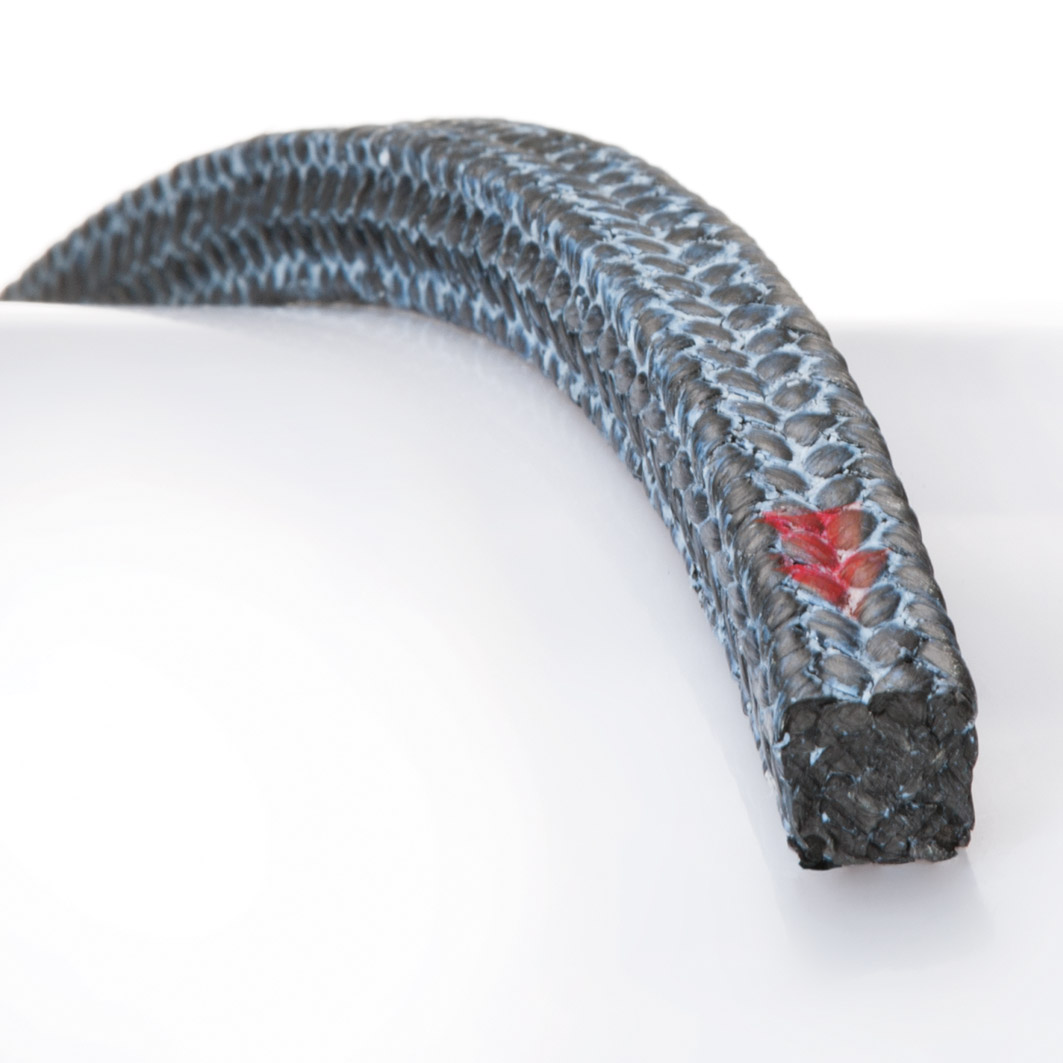

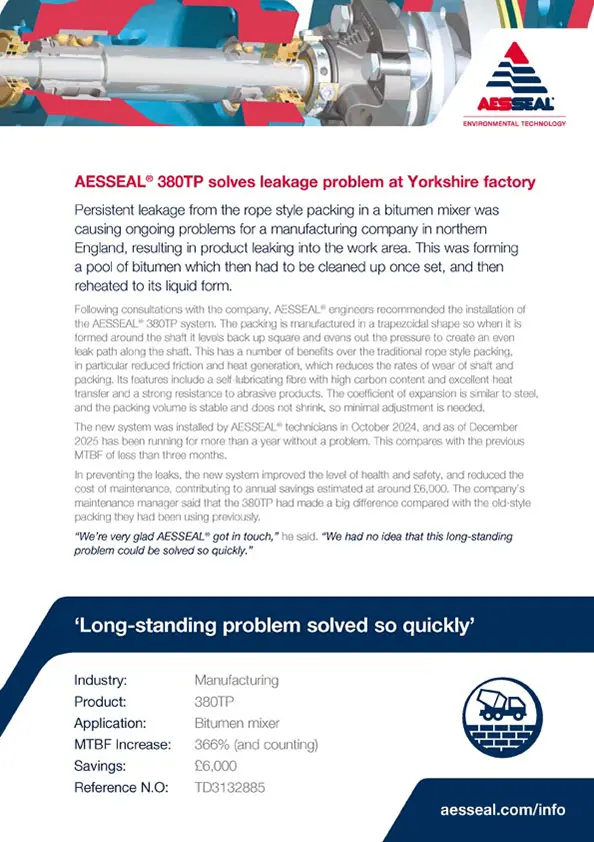

Persistent leakage from the rope style packing in a bitumen mixer was causing ongoing problems for a manufacturing company in northern England, resulting in product leaking into the work area. This was forming a pool of bitumen which then had to be cleaned up once set, and then reheated to its liquid form.

More Industry Related Content