Case Ref

TD3107678

Country

Sweden

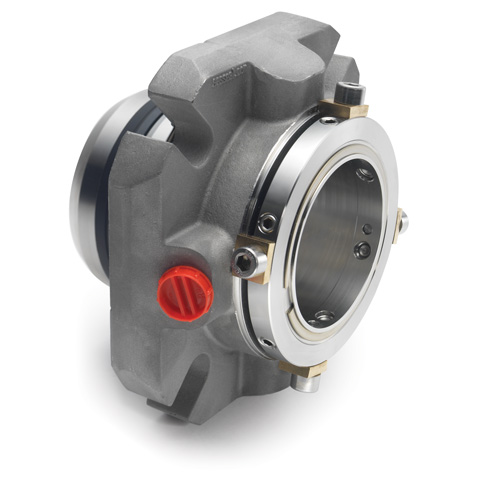

A pulp and paper company in Sweden was having problems with the persistent failure of the seal on a hot boiler application. Ineffective cooling of the sealing water and the inability of the elastomers to cope with the high temperatures meant that the seal was failing every three to four months.

More Industry Related Content