More Industry Related Content

By Fred Osborn

What was the main problem the company was facing and how long had they been struggling to find a solution?

It culminated when the split seal on the agitator failed dramatically due to a lance that fell from the soot blowers and got caught in the propeller of the agitator, bending the shaft and the seal subsequently failed.

Was the DMSC double cartridge mechanical seal solution, FLOWTRUE meter and SW2 water management system combination an obvious solution or did it take a long time to decide what was needed?

It was obvious from previous experience at their sister mill.

How serious would the problem have become if a solution had not been found?

It would have severely hampered their production.

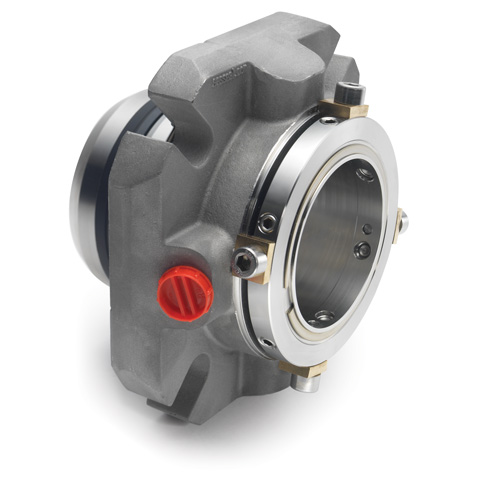

What made it ideal for the conditions the machinery was operating in?

A close clearance bushing to stabilize the shaft, a FlowTrue, W2, and a DMSC.

Was this an existing customer? Did they approach AESSEAL and how pleased were they with the work?

It was an existing customer and they were ecstatic that we solved the problem.

How much money will this have saved them and has AESSEAL received any more orders as a result?

The boiler has not shut down due to seal issues since these were installed. Orders for both agitators were provided along with spares for them.