Case Ref

CH01447

Country

South Africa

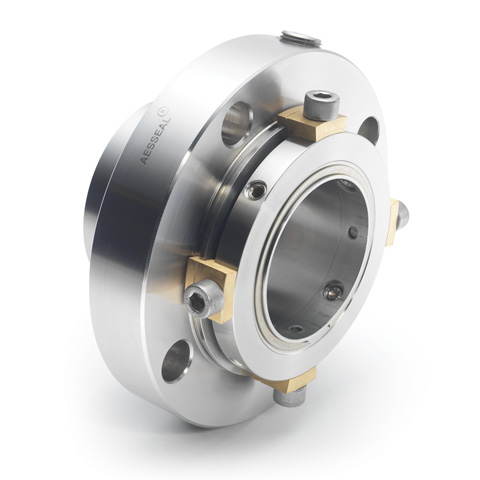

A major oil refinery in South Africa had an unreliable mechanical seal on a cooler water pump. Despite competitors trying a number of different seal support system configurations, the seal was failing approximately every 6 to 9 months. This was as a result of dry running, causing vaporisation, damaged elastomers, seal face wear and pump bearing failure as a result of heat transfer.

More Industry Related Content

More API Related Content