More Industry Related Content

With Fredrik Sternvad

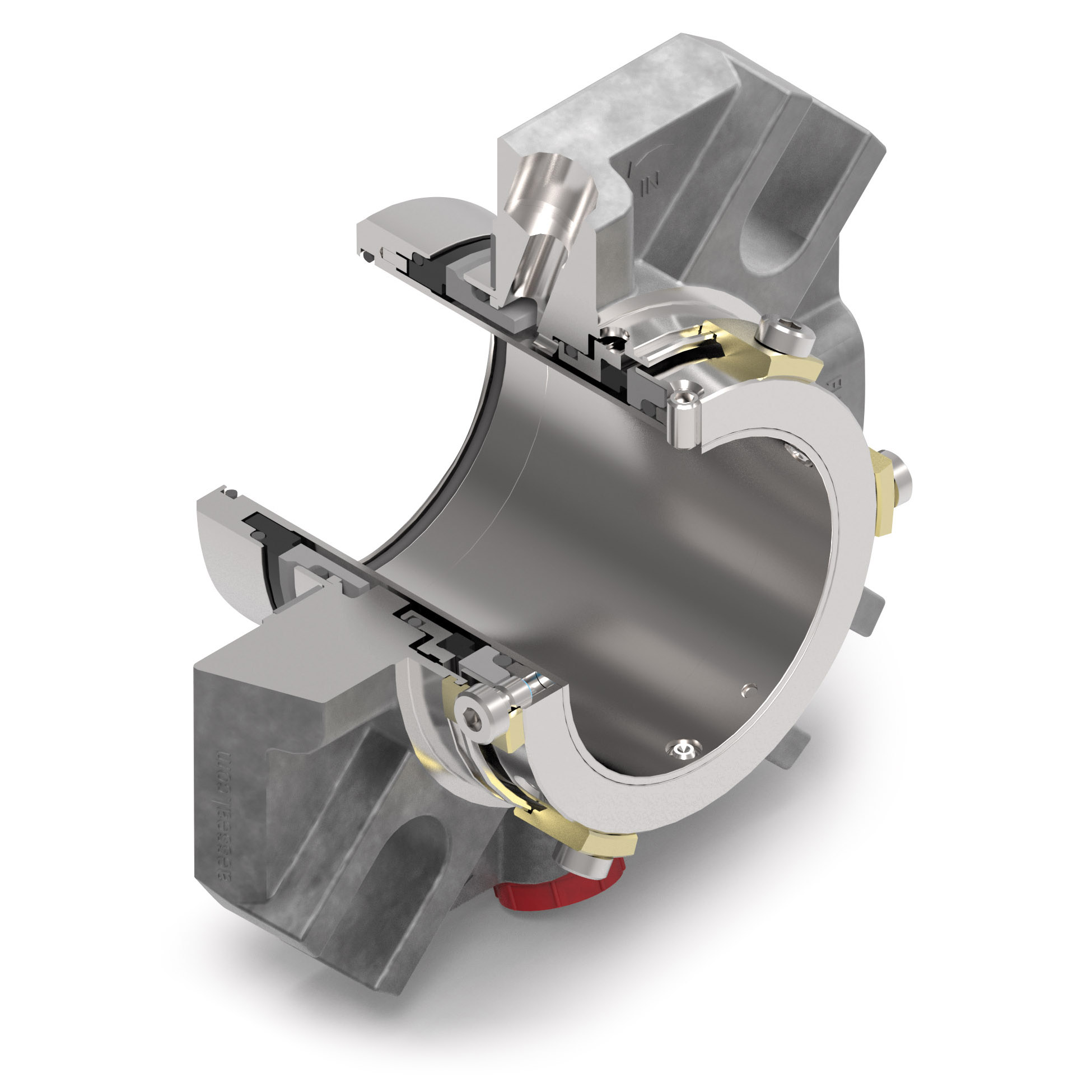

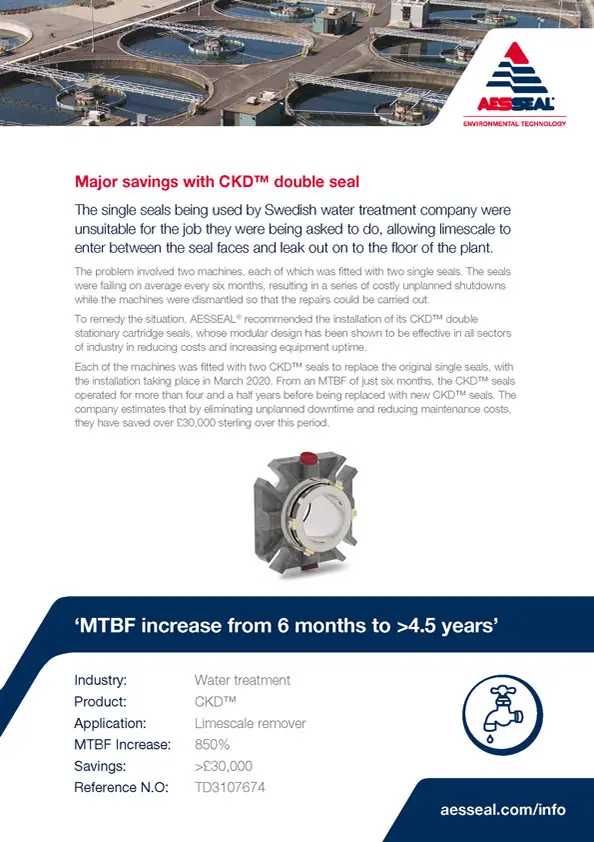

Single seals were leaking onto the floor of a Swedish water treatment plant as they were overwhelmed by limescale. Failure was routine and costly, until AESSEAL stepped in. AESSEAL Sweden’s technical sales manager Fredrik Sternvad talks us through the process.

What was the main problem the company was facing and how long had they been struggling to find a solution?

The main problem was leakage and the fast current shutdowns. The word I got from the customer was years.

Why were the seals overwhelmed and leaking?

The seals were not flushed and the limescale water was not sufficient. The limescale was packed inside the seals, getting the springs etc “bound up”.

How long did it did them to dismantle their machines each time there was a breakdown?

It took two people around one working day.

Was the solution instant?

Yes.

What would have happened if the CKD seals hadn’t been installed?

I guess the customer would have kept on running the expensive seals they were using, with leakage and all.

Was this an existing customer? Did they approach AESSEAL and how pleased were they with the work?

Yes, they had purchased some component seals from us earlier. They did approach us to have a look at this application. The customer is really happy, especially the maintenance personnel, that earlier had to wash all the floors and parts of the machine in time and out of time.

How much money will this have saved them and has AESSEAL received any more orders as a result?

I would think about $40K over the period, all in all. Yes, we have received further orders for CRCO seals.