More Industry Related Content

With Pieta Engles

How did the contract come about?

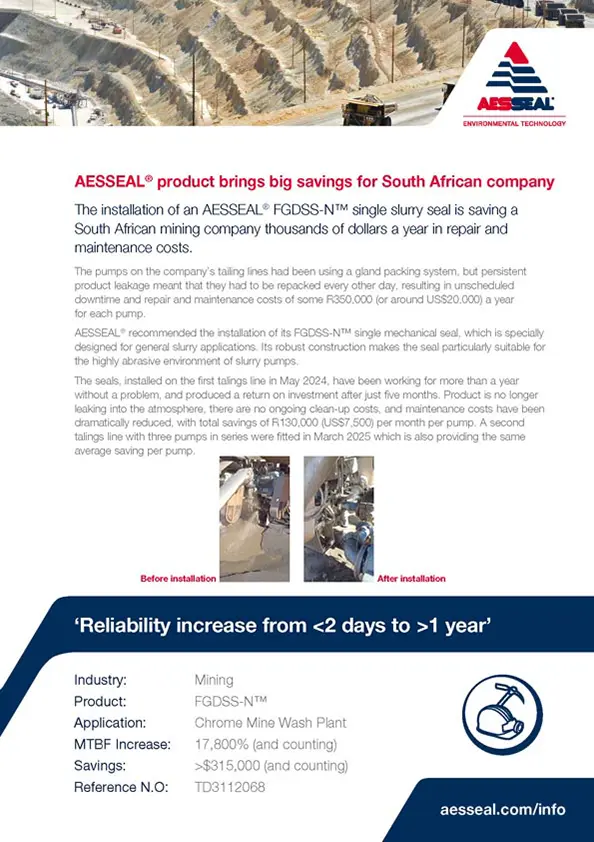

The six pumps on the company’s tailing lines had been using a gland packing system, but the stuffing box arrangement was proving very unreliable. Persistent product leakage meant that the pumps had to be repacked every other day, resulting in unscheduled downtime and repair and maintenance costs of some R350,000 (or around US$20,000) a year for each pump.

Was this an existing customer?

We were already supplying the company with bearing isolators and mechanical seals. Advances in technology meant that AES sales engineers were very confident about the reliability of the AESSEAL® FGDSS-NTM single slurry seal, which showed itself able to withstand the very high pressure and high specific gravities of slurry applications. Following the introduction of the product at a seminar in February 2024, the decision was taken to offer the seal as a possible solution to the uniquely demanding conditions to be found on tailing lines.

How did you convince the company that this seal was the right solution?

We formulated a strategic marketing plan which included an onsite investigation of the application, presentations accompanied by quotes and a prediction of the return on investment, which we calculated was only 90 days. The negotiations with the customer involved meetings with four departments, which alone meant about 48 hours spent driving to and from the plant, (around 4500 km in total). Three months after the initial approach we were given a trial order in May 2024 for installation on a single pump. Once that was received we were able to install and commission the seal in just two weeks.

What advantages did the AESSEAL® single slurry seal offer to the customer?

There was an immediate improvement in reliability, which meant lower labour costs, reduced maintenance, reduced inventory on spare parts, and lower energy consumption, all of which contributed to an increase in production efficiency. The proven effectiveness of the seal led to further orders, so that it has now been fitted to a total of five pumps. The first one has now been operating successfully for over à year, and we monitor all of them on a regular basis to ensure that they are working effectively.

Have you received feedback from the customer about their performance?

Yes. There is constant communication between the company and the distributing agent who visits the site every second week. There are currently negotiations in place to plan for the other installations. The customer has calculated the total cost saving on the first pump alone to be more than R760,000 (US$42,000). The success of this installation meant that we were able to approach other mining companies with a case study which showed the effectiveness of the AESSEAL® single slurry seal. One result is that our current quote values for this product have increased dramatically.