Case Ref

2292-2297

Country

United Kingdom

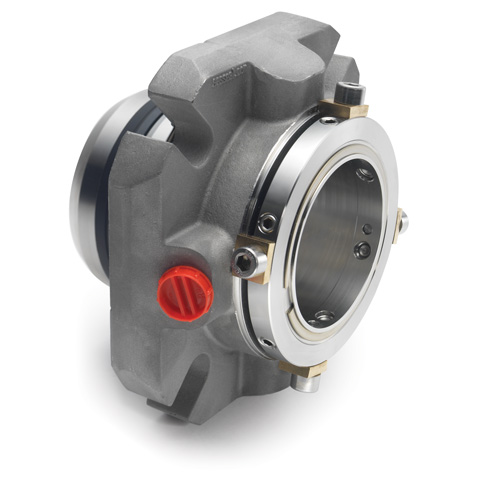

Between 2002 and 2003 AESSEAL® worked with a major UK Chemical company to improve reliability and reduce the amount of water used by its sealing solution on its nylon production site.

More Industry Related Content