With one of the biggest corrugated cardboard manufacturing factories in Europe, a French cardboard manufacturer was experiencing seal failures every two months. AESSEAL® worked closely with the customer to find the right solution.

More Industry Related Content

By Alexandre Olivier

What was the main problem the company was facing?

The equipment had been fitted with a competitor’s single sealing solution for a long time and it was no longer working, with water leaking onto the seal and causing damage. The process pressure is three bar, which very quickly led to a build-up of pulp between the faces of the original single mechanical seal, which is lubricated by the process. There were clear signs of contact marks.

It was obviously a big operation – 180,000 tonnes of paper every year. How serious would the problem have become if a solution had not been found?

They were facing this issue on a regular basis and it was included in the maintenance plan, so they were throwing money out of the window.

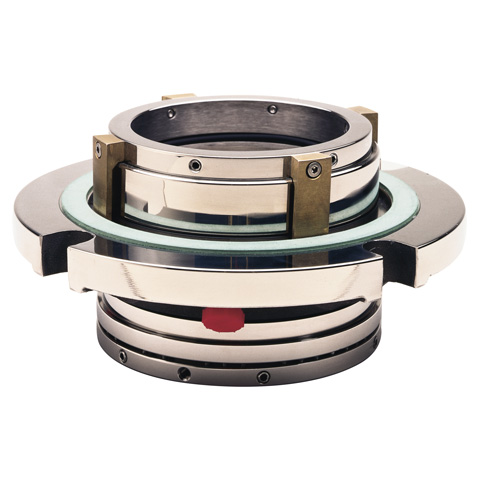

What made the IADC combined with a SW2 seal support system the ideal answer and was it obvious to you?

We made a decision as to what was needed in a short time and there has been no equipment failure since 2019. The IADC mechanical seal, which we fitted with a lubrication pot, is designed for use on screens and knotters, so was ideal for this situation, and we added a stainless steel filter with support to ensure good water quality without particles. The stuffing box also had to be modified to accommodate the inlet/outlet of the barrier fluid.

Was this an existing customer? Did AESSEAL receive any more orders as a result?

This was quite a new customer when we supplied them with this seal and they were delighted with the results. They are now a regular customer with around €100,000 orders turnover a year.

How much money did this save them?

With production stoppage time, replacing the equipment every two months and the cost of labour, it was costing them around €130,000 a year. They got a return on their investment in the first month and, based upon previous maintenance costs and savings from seal fitting, have now saved more than €750,000.