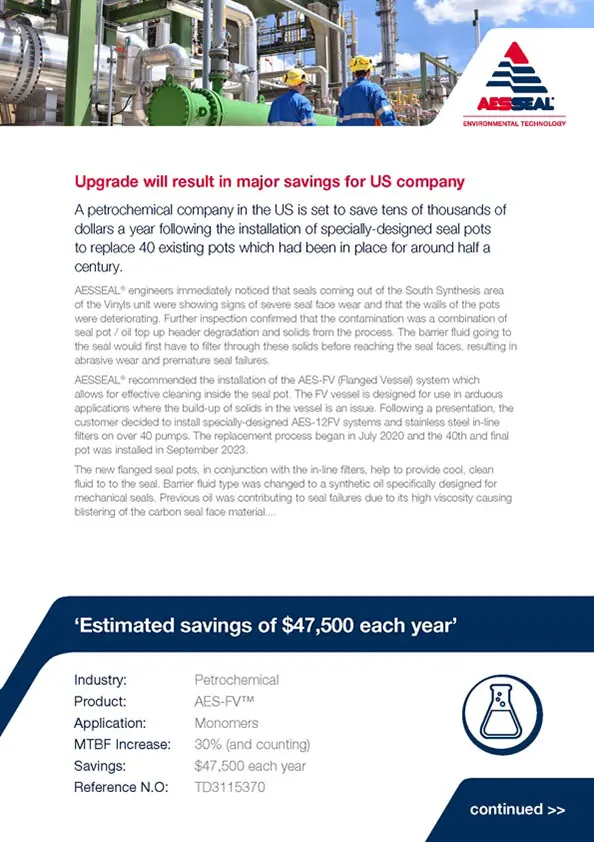

A US petrochemical company is set to save tens of thousands of dollars a year following the installation of specially-designed seal pots to replace 40 existing pots which had been in place for around half a century.

Custom Design Case Studies

Superior AESSEAL product and service seals the deal

A company in Ireland specializing in the production of innovative coats, paints, and specialty materials requested the assistance of AESSEAL Ireland to repurpose a stainless steel Chemineer GTN agitator and wet double seal to accommodate a new product.

CAPI-TXS the answer for legacy quench oil pumps

The single seals on three BB2 hot quench oil pumps at a petrochemical plant in the north of England were regularly failing due to poor face lubrication by the product.

AESSEAL product removes risk of HFC emissions

A specially designed double seal from AESSEAL has enabled an Italian drinks company to avoid the risk of major financial penalties which could have resulted from the release into the atmosphere of highly damaging HFC (hydrofluorocarbon) gases.

AESSEAL ES the choice for easy installation

During a dry dock service at an Abu Dhabi port, the customer specializing in dredging and maritime services approached AESSEAL Marine plc with an ongoing issue. Their existing single component seal involved a complex installation process which often proved difficult to carry out correctly.

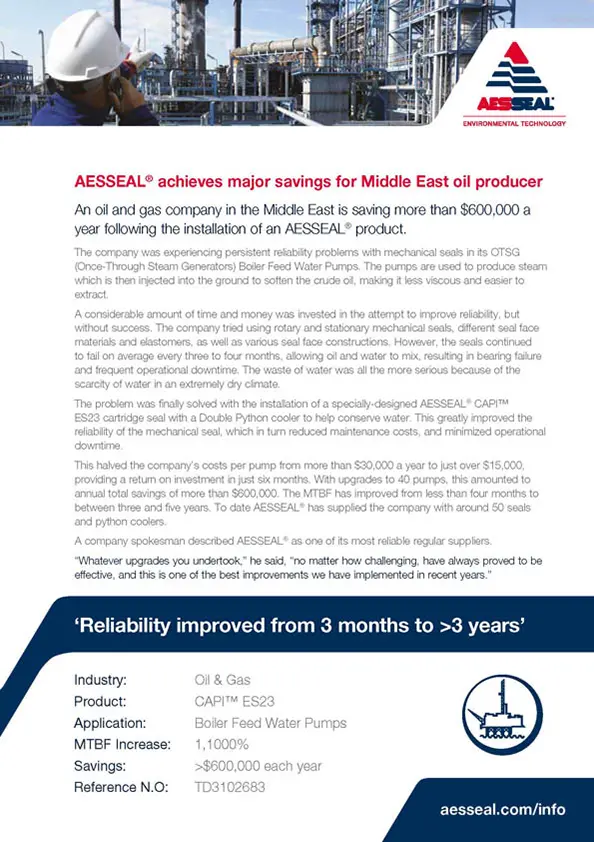

AESSEAL achieves major savings for Middle East oil producer

An oil and gas company in the Middle East is saving more than $600,000 a year following the installation of an AESSEAL product.

Company makes huge savings with AESSEAL system

A water company in the Middle East has saved almost a quarter of a million dollars following the installation of an AESSEAL bearing protector.

UK oil refinery close to shutting down following labyrinth seal failure

At an oil refinery a labyrinth seal failed and it was not possible to get a replacement, they called on AESSEAL for help.

Improved reliability for new process

A refinery in Canada were commissioning a new lipids coprocessing initiative where renewable feedstock is injected into the cracker.

New seal design the difference at US firm

Reliability problems leading to significant downtime and high maintenance costs at pulp and paper company.

Reduced downtime, improved safety

Using gland packing to seal an Armstrong – Chemtec crystalliser.

Reliability upgrade eliminates unscheduled downtime

An oil refinery in the USA was experiencing excessive seal failures with some even leaking straight from start up.

Tailored seal solution cuts costs and operational downtime

A global food and beverage manufacturer in Poland, was experiencing problems with a fan fume pumping toxic fumes as a by-product of the distilling process.

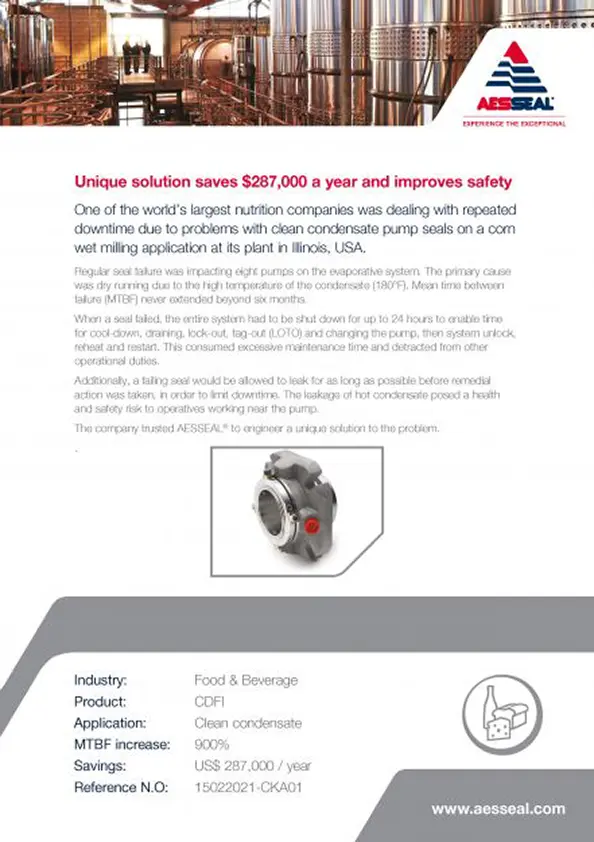

Unique solution saves $287,000 a year and improves safety

One of the world’s largest nutrition companies was dealing with repeated downtime due to problems with clean condensate pump seals on a corn wet milling application at its plant in Illinois, USA.

Improving reliability, increasing efficiency

A leading refinery in the UK was having trouble with seal leakage from existing carbon box technology on their 150#, 600# steam turbines.

Eliminating a $225,000 maintenance bill

A leading food processor was experiencing problems sealing two Nash Vacuum pumps