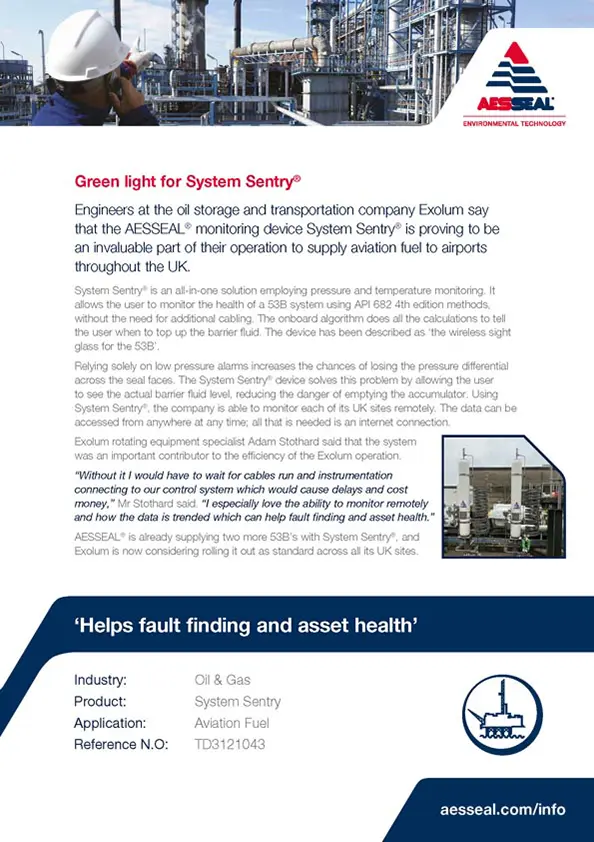

Engineers at the oil storage and transportation company Exolum say that the AESSEAL monitoring device System Sentry is proving to be an invaluable part of their operation to supply aviation fuel to airports throughout the UK.

Energy Savings Case Studies

Polish plant benefits from LabTecta protection

A chemical plant in Poland has saved 12,000 złotys (about US$3,000) over the past 12 months after it fitted a LabTecta bearing protector to a faulty seal.

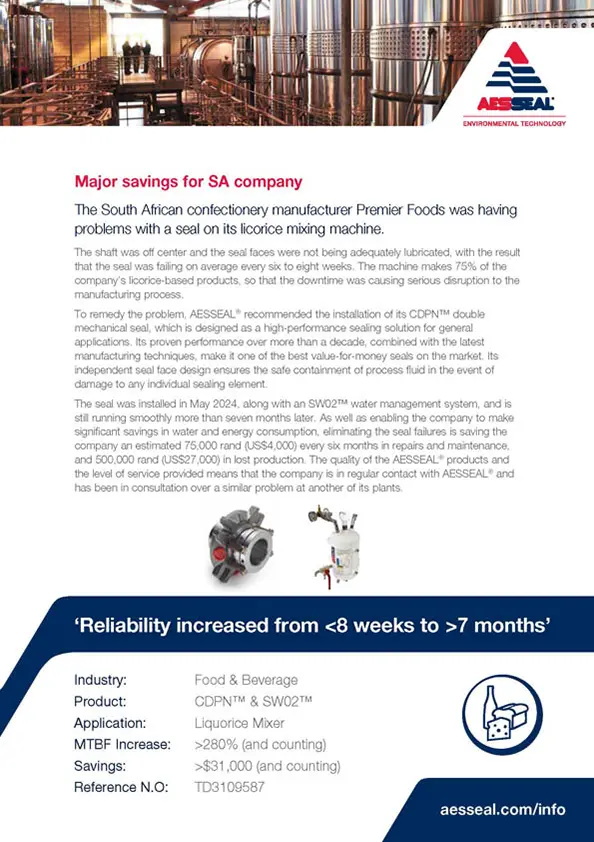

Major savings for SA company

The South African confectionery manufacturer Premier Foods was having problems with a seal on its licorice mixing machine.

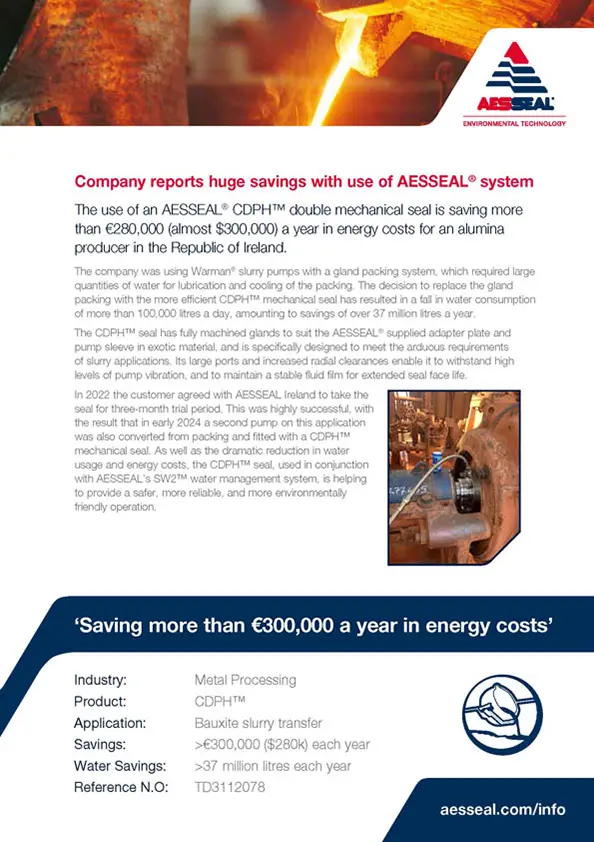

Company reports huge savings with use of AESSEAL system

The use of an AESSEAL CDPH double mechanical seal is saving more than €280,000 (almost $300,000) a year in energy costs for an alumina producer in the Republic of Ireland.

CDPH brings big savings for Botswana company

The replacement of a graphite packing system on a cyclone feed pump with the more efficient AESSEAL CDPH double mechanical seal.

CDSA provides major savings for German company

A German paper and packaging plant has reported significant savings and improved reliability following the installation of CDSA double cartridge mechanical seals.

System Sentry proves its worth in INEOS field trial

Engineers at the petrochemicals manufacturer INEOS have given the seal of approval to the AESSEAL® monitoring device System Sentry® following a field trial at the company’s plant in Hull in the east of England.

CDM reliability the answer for seal failures

A corrugated packaging plant in northern France was experiencing persistent seal failures, on average every two months.

Seal failures solved at US company

The installation of double cartridge mechanical seals and a water management system has solved a persistent and costly problem at a US paper mill

Leakage problem solved with STS

A global energy company was facing significant losses as a result of damage to the steam turbine housing at one of its ethylene plants.

STS steam seal updates UK Ethylene plant

AESSEAL stepped in when a mission critical general purpose steam turbine at a UK Ethylene production facility developed leaks and the original OEM seal housing was no longer available. We updated the 40-year-old turbine with a modern non contacting STS mechanical seal within two weeks.

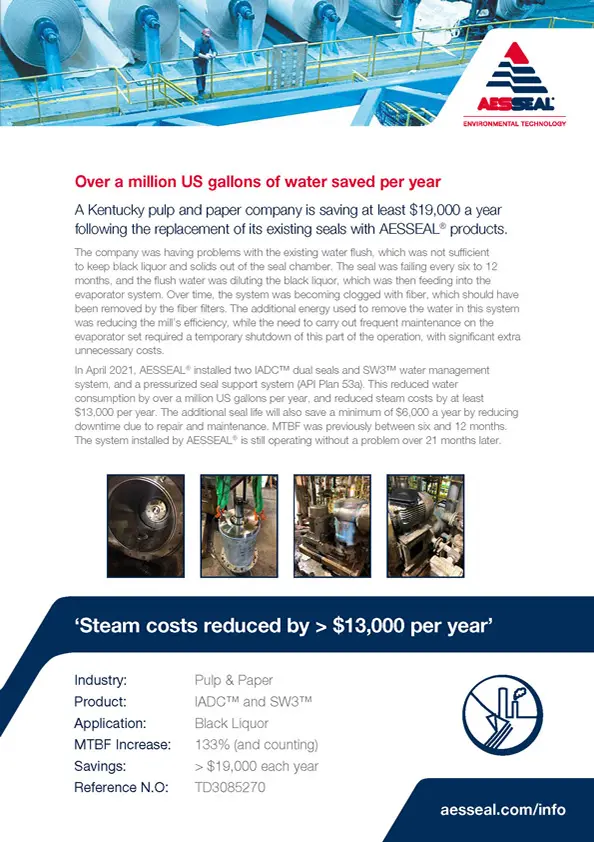

Over a million US gallons of water saved

A Kentucky pulp and paper company is saving at least $19,000 a year following the replacement of its existing seals with AESSEAL products.

Full steam ahead for refinery after change to STS seals

An oil and gas refinery in northern England was experiencing poor reliability of its steam turbine.

Efficient seal support system reduces energy costs

A chemicals manufacturer in the USA was concerned about high energy associated with the sealing of a hot glycol pump.

Eliminating over 61 million gallons of water from 26 evaporator pumps

Evaporator steam use reduced by 103,000klbs a year by eliminating over 61 million gallons of water from 26 evaporator pumps

Reliability Improved For Waste Energy Company

Enfinium were disappointed with the support provided by their pump OEM

Seal upgrade saves cornmill $280,000 in repairs and downtime

Cargill Corn Milling Inc was experiencing leakage on the seals of a boiler feed pump at its plant in Iowa, USA.

Replacing lip seals improves reliability and saves energy

A major nutrition product producer was having problems with bearing reliability on one of its incline screw conveyors on one of its UK production facilities.

Catalogue of issues lead to failures on power station valves

A South African power station were experiencing regular outages leading to expensive downtime along with poor emission control and high energy losses.

Energy Savings for Italian Corn Miller

An Italian corn miller used Clean In Place (CIP) water to cool and lubricate thier mechanical seals. This water cannot be drained to the plant depuration system but must be recirculated into the system loop with a high cost in energy in order to reheat and evaporate.

Paper producer saves more than one million Dollars per year

A leading North American producer of Pulp and Paper recognise the importance of operating their business in a sustainable way.

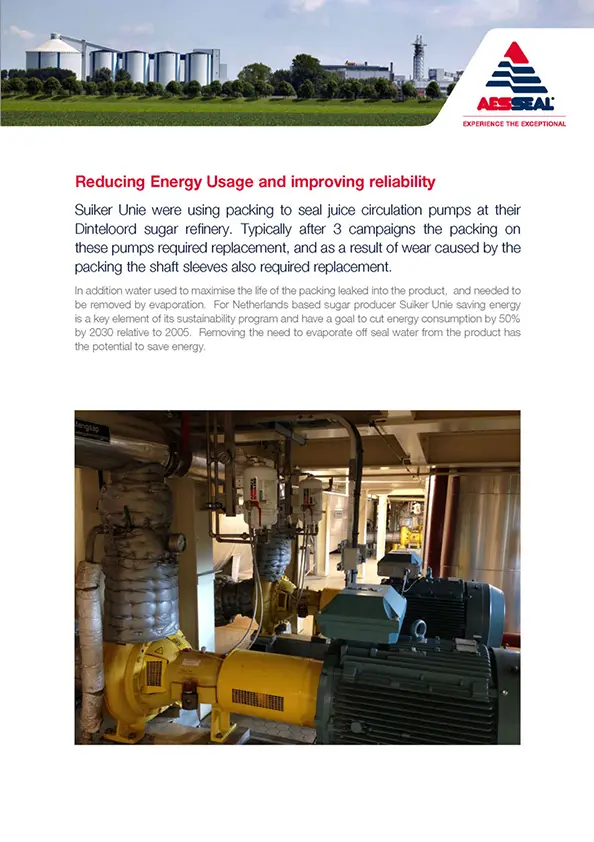

Reducing Energy Usage and Improving Reliability

Suiker Unie were using packing to seal juice circulation pumps at their Dinteloord sugar refinery.

Eliminating a $225,000 maintenance bill

A leading food processor was experiencing problems sealing two Nash Vacuum pumps

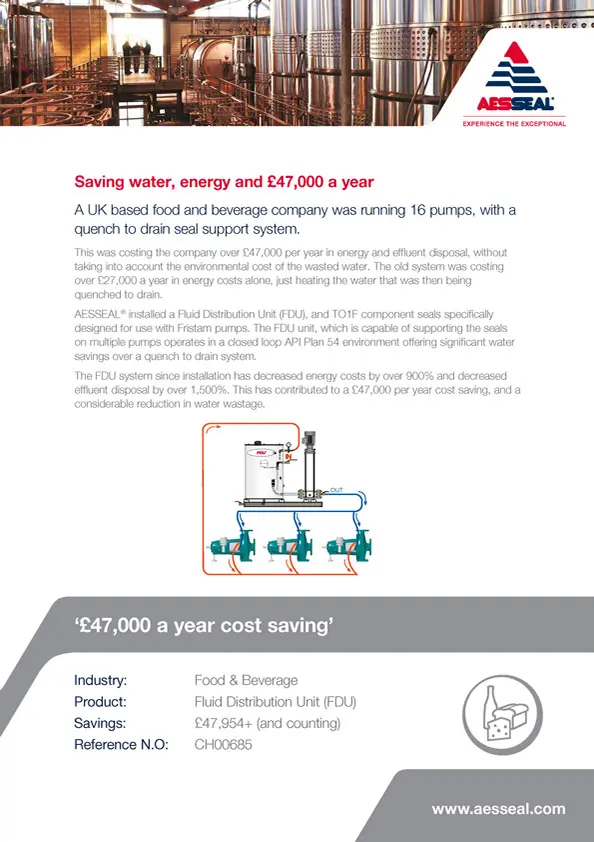

Saving water, energy and money for a food manufacturer

16 pumps, with a quench to drain seal support system.

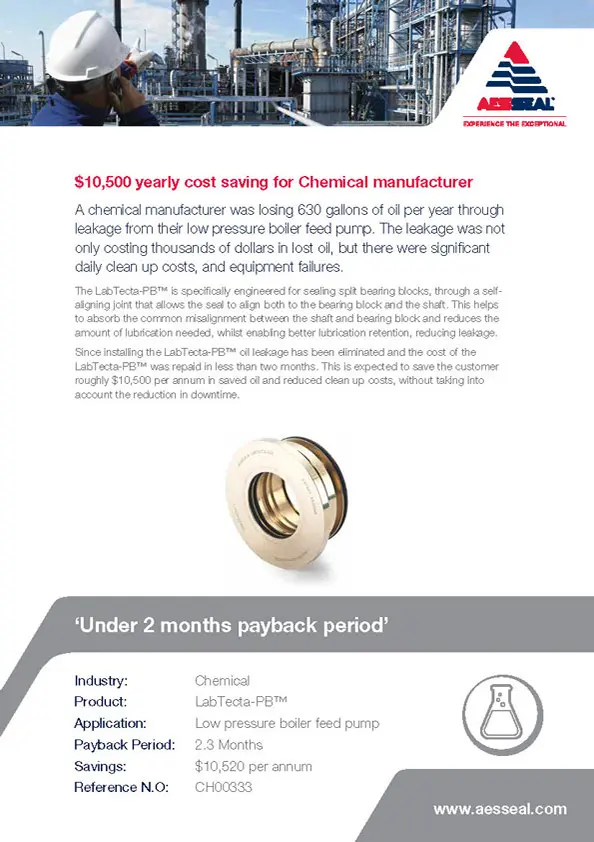

$10,500 yearly cost saving for Chemical manufacturer

Eliminating oil leakage from a boiler feed pump with a LabTecta-PB™ that is specifically designed for sealing split bearing blocks.