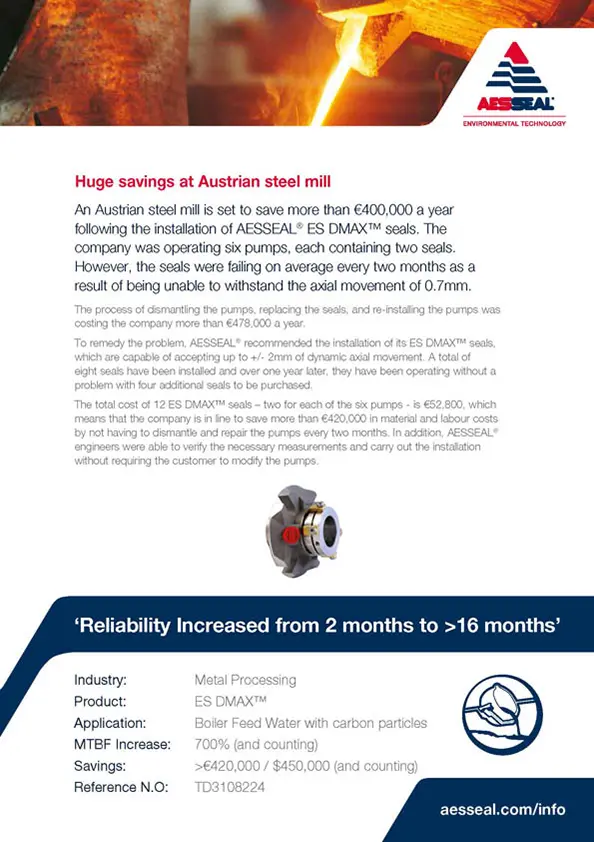

Case Ref

TD3108224

Country

Austria

An Austrian steel mill is set to save more than €400,000 a year following the installation of AESSEAL® ES DMAX™ seals. The company was operating six pumps, each containing two seals. However, the seals were failing on average every two months as a result of being unable to withstand the axial movement of 0.7mm.

More Industry Related Content