The use of an AESSEAL CDPH double mechanical seal is saving more than €280,000 (almost $300,000) a year in energy costs for an alumina producer in the Republic of Ireland.

Metal and Glass-Working Case Studies

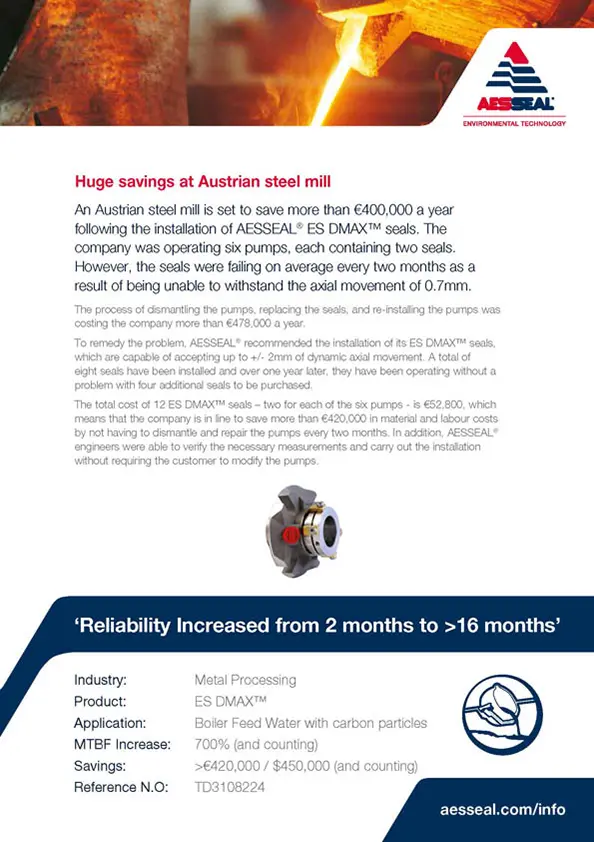

Huge savings at Austrian steel mill

An Austrian steel mill is set to save more than €400,000 a year following the installation of AESSEAL ES DMAX seals. The company was operating six pumps, each containing two seals.

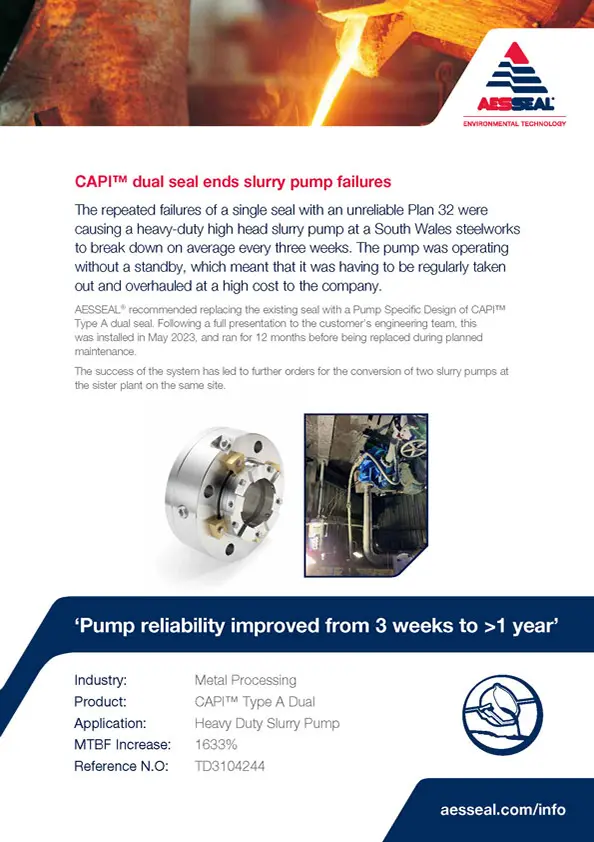

CAPI dual seal ends slurry pump failures

The repeated failures of a single seal with an unreliable Plan 32 were causing a heavy-duty high head slurry pump at a South Wales steelworks to break down on average every three weeks.

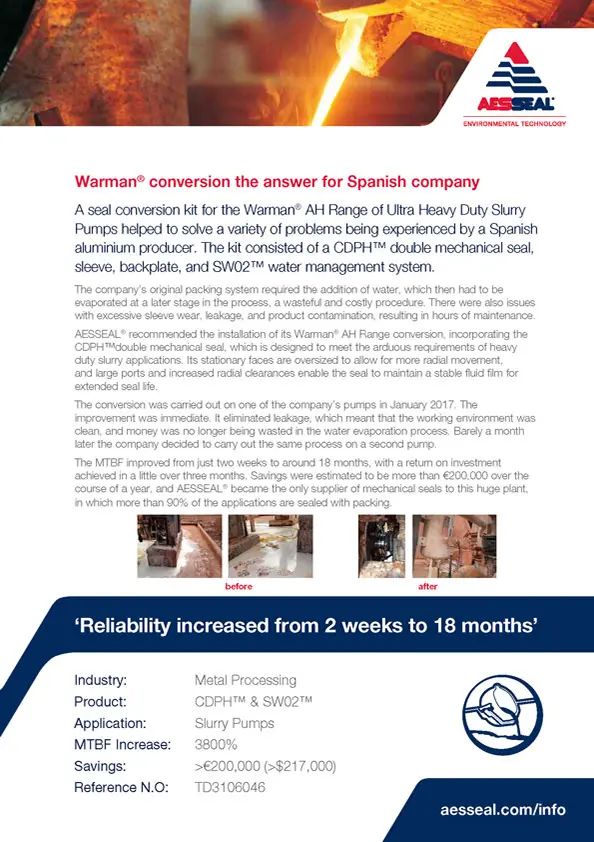

Warman conversion the answer for Spanish company

A seal conversion kit for the Warman® AH Range of Ultra Heavy Duty Slurry Pumps helped to solve a variety of problems being experienced by a Spanish aluminium producer.

LabTecta the remedy for lip seal failures

The lip seals in use at a north of England glass manufacturer were wearing out after just a few weeks

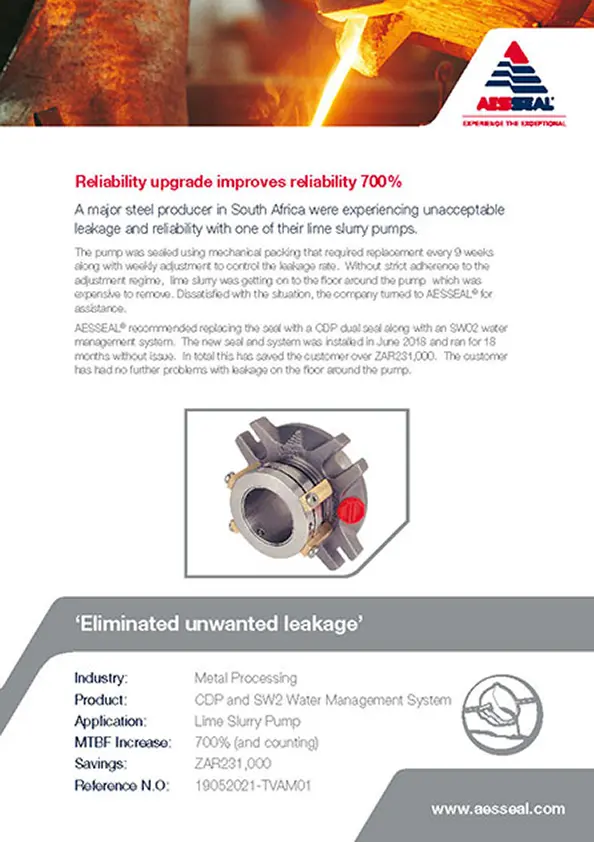

Reliability upgrade improves reliability 700%

A major steel producer in South Africa were experiencing unacceptable leakage and reliability with one of their lime slurry pumps.

Seal upgrade improves reliability and simplifies maintenance

A major integrated zinc / lead smelter company in Canada was unhappy with the performance of the existing mechanical seal.

Improved Safety and Reliability

A major manufacturer in the UK were having reliability issues with the seal on a critical Labour chemical pump used to pump caustic solution.

Zinc Smelting Plant Saves Thousands

Experiencing repeat leakage of a highly abrasive zinc oxide and sulphuric acid solution

AESSEAL upgrade solution leads to an 8 year failure free period

Upgrading from gland packing to a dual seal and system helps eliminate seal failure due to inconsistent water supply.