The repeated failure of seals on heater drainage pumps was causing problems for a power generation company in Botswana.

Training Advice Case Studies

Major savings for SA company

A South African coal mining company is making significant savings following a decision to send its CDPH heavy duty slurry seals directly to AESSEAL for reconditioning.

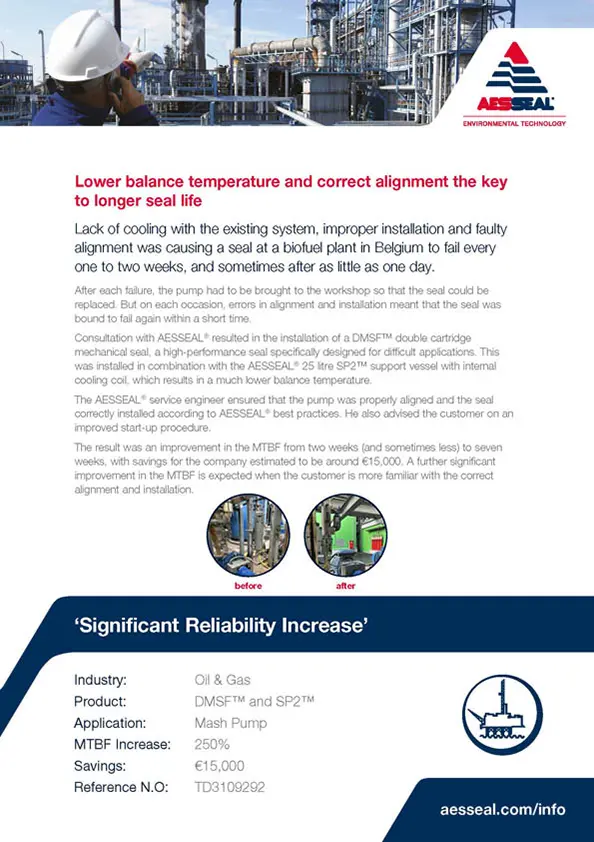

Lower balance temperature and correct alignment the key to longer seal life

Lack of cooling with the existing system, improper installation and faulty alignment was causing a seal at a biofuel plant in Belgium to fail every one to two weeks, and sometimes after as little as one day.

Seal still giving perfect service after more than ten years

An AESSEAL RDS split seal installed at a US paper mill in January 2014 is still in full operation more than ten years later.

AESSEAL repair saves thousands for Saudi company

A Saudi Arabian chemical company has saved thousands of dollars in repair costs following an intervention by AESSEAL engineers.

Spanish company cuts costs with CURC

An automotive manufacturing company in north-western Spain was unhappy with the service from its seals supplier, whose products were failing after less than six months, causing chemicals to leak into the work environment.

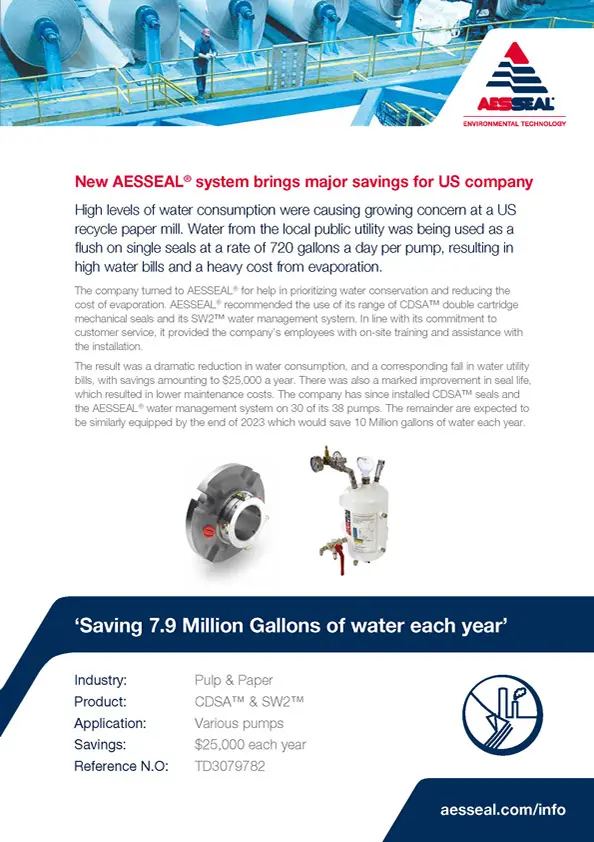

New AESSEAL system brings major savings for US company

High levels of water consumption were causing growing concern at a US recycle paper mill. Water from the local public utility was being used as a flush on single seals at a rate of 720 gallons a day per pump, resulting in high water bills and a heavy cost from evaporation.

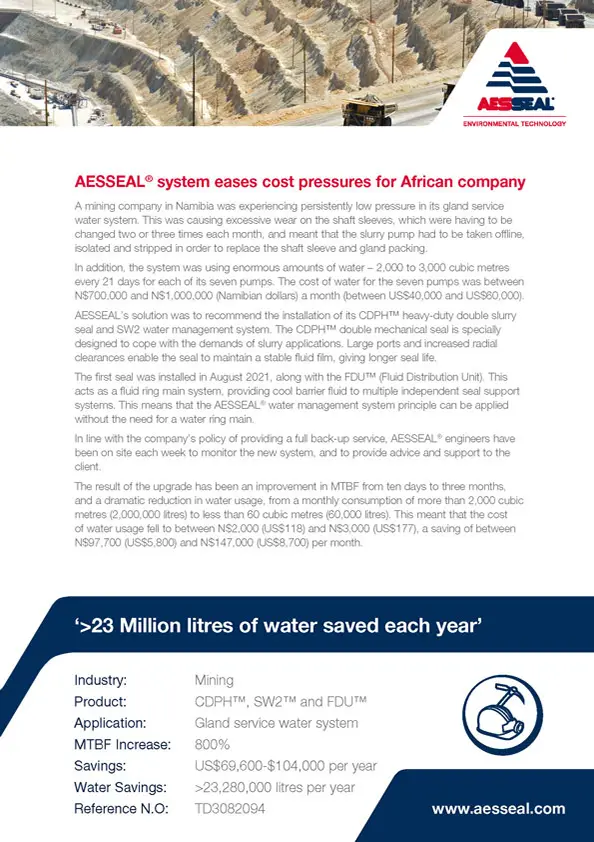

AESSEAL system eases cost pressures for African company

A mining company in Namibia was experiencing persistently low pressure in its gland service water system. This was causing excessive wear on the shaft sleeves.

Quality service and technical support for South African contract

lack of technical and service support led the South African company COFCO International to approach AESSEAL

Massive water savings with improved reliability

A Bio Products manufacturer was concerned about the water used by the sealing systems at one of its manufacturing facility in the USA.

Catalogue of issues lead to failures on power station valves

A South African power station were experiencing regular outages leading to expensive downtime along with poor emission control and high energy losses.

Training and support leads to reliability

Ongoing reliability issues with their pulp agitator mechanical seals led Australian pulp and paper manufacturer to turn to AESSEAL® for assistance.