Featured Case Studies

The case studies below showcase the very best of commitment to excellence at AESSEAL across our three core pillars:

- Exceptional Customer Service – putting customers first, every time.

- Advanced Technology – delivering innovation that drives results.

- Sustainable Solutions – engineering a better future for people and our planet.

LabTecta ends dust pollution problem for SA firm

Preventing dust from escaping into the working environment and is saving thousands of dollars a year

Seal upgrades save over US $3.4million in seven years

AESSEAL solves reliability problem for US paper company

Annual savings of over $2.6 million

CDSA seals brings huge savings for US company

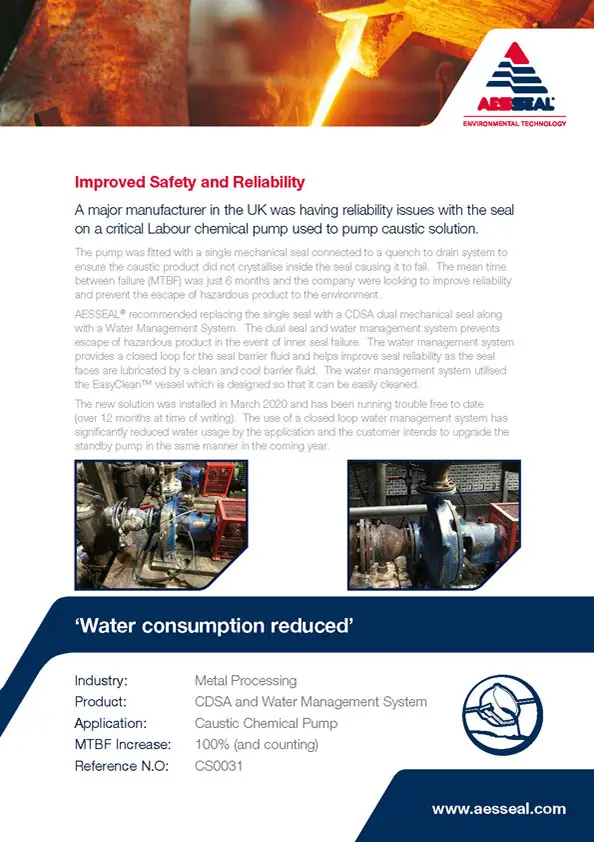

Improved Safety and Reliability

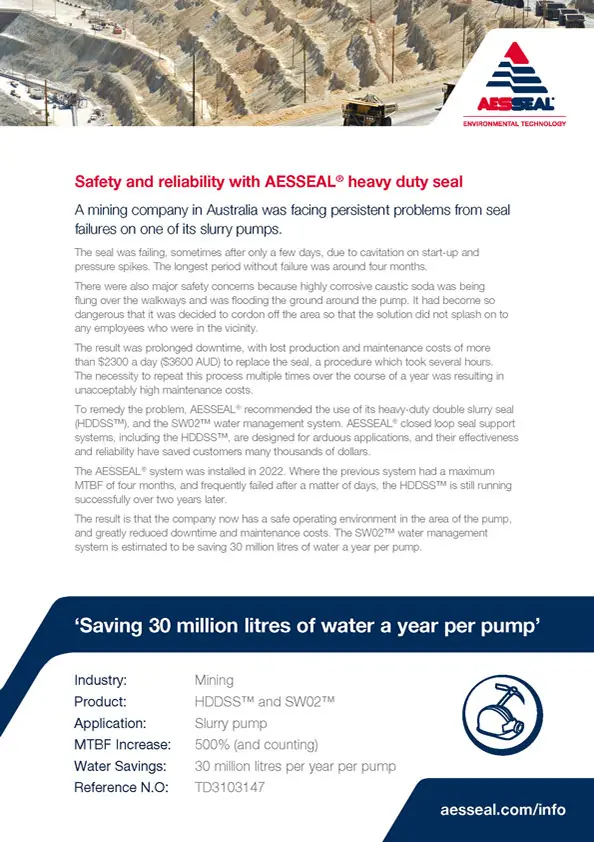

Safety and reliability with AESSEAL heavy duty seal

A mining company in Australia was facing persistent problems from seal failures on one of its slurry pumps.

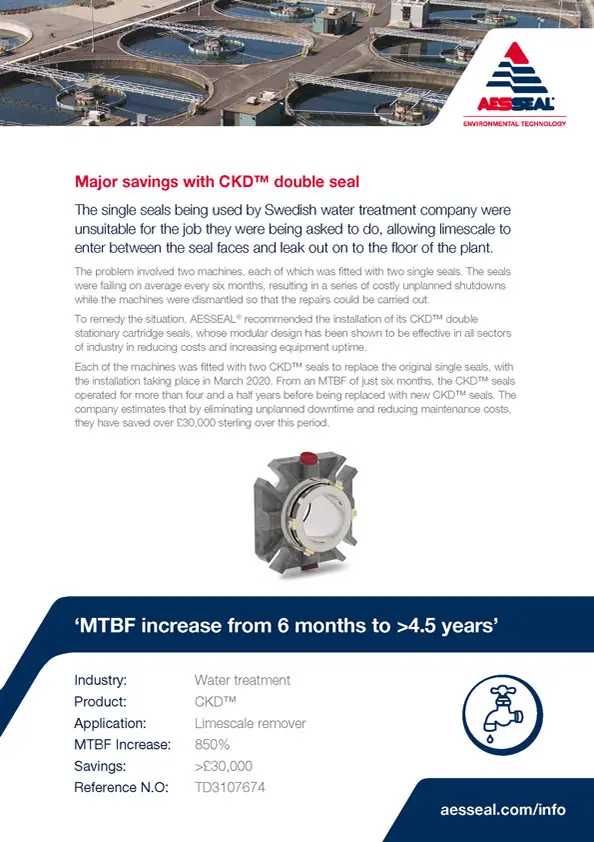

Major savings with CKD double seal

AESSEAL product removes risk of HFC emissions

DMSF seal the answer at South African plant

Rapid response impresses Saudi customer

Sourced and supplied a replacement seal in just two weeks for customer’s Oil and Gas operation in Saudi Arabi

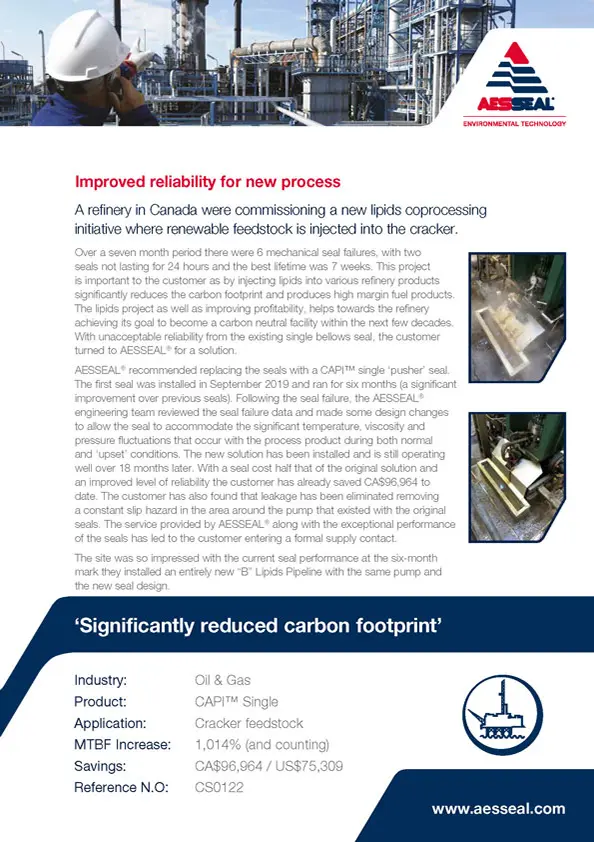

Improved reliability for new process

Rapid response saves the day for UK company

Change to packing saves Swiss company $millions

A chocolate producer in Switzerland has saved around ₣2.3 million ($2.6 million) over the past year following its decision to change to an AESSEAL pump packing system.

Fantastic seal life for notoriously difficult application

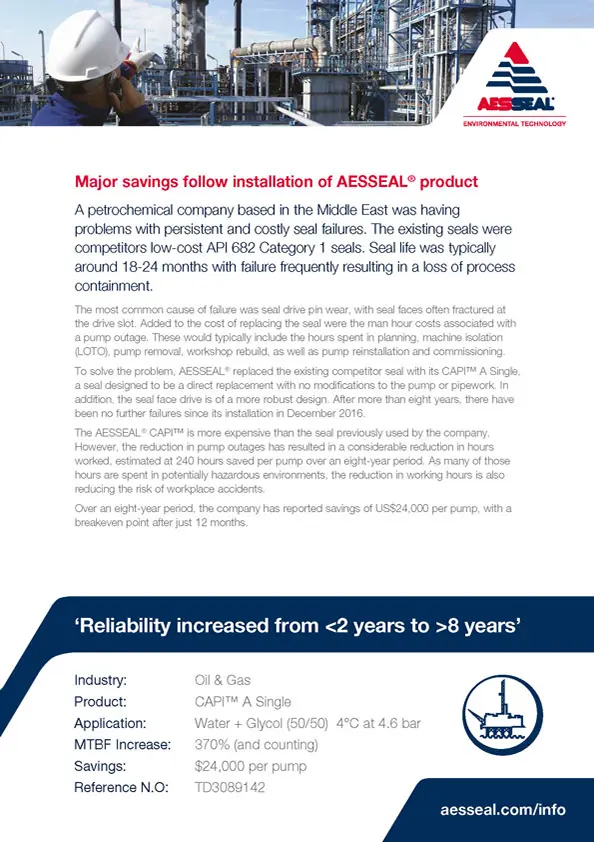

Major savings follow installation of AESSEAL product

A petrochemical company based in the Middle East was having problems with persistent and costly seal failures.

AESSEAL upgrade removes safety risk

FIDC ends costly leaks at US firm

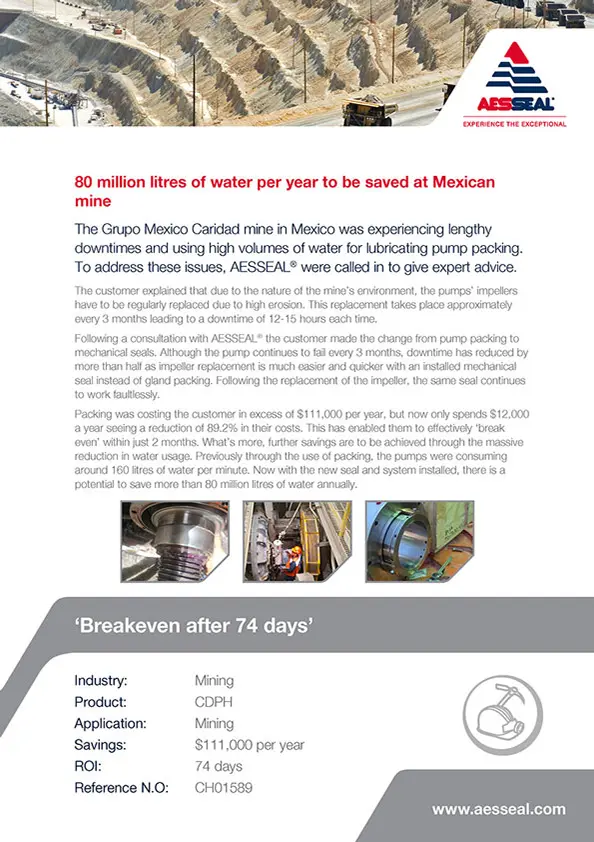

80 million litres of water per year to be saved at Mexican mine

Bitumen pump upgrade saves over £23,000 a year

Asphalt producer pump for road surfaces was gland packed and losing over 15 tonnes of bitumen.

Staying cool in Cardiff

Company makes huge savings with AESSEAL system

Dangerous oil leak problem solved by LabTecta FS

Navy reduces repair times and improves pump reliability

Reliability Improved For Waste Energy Company

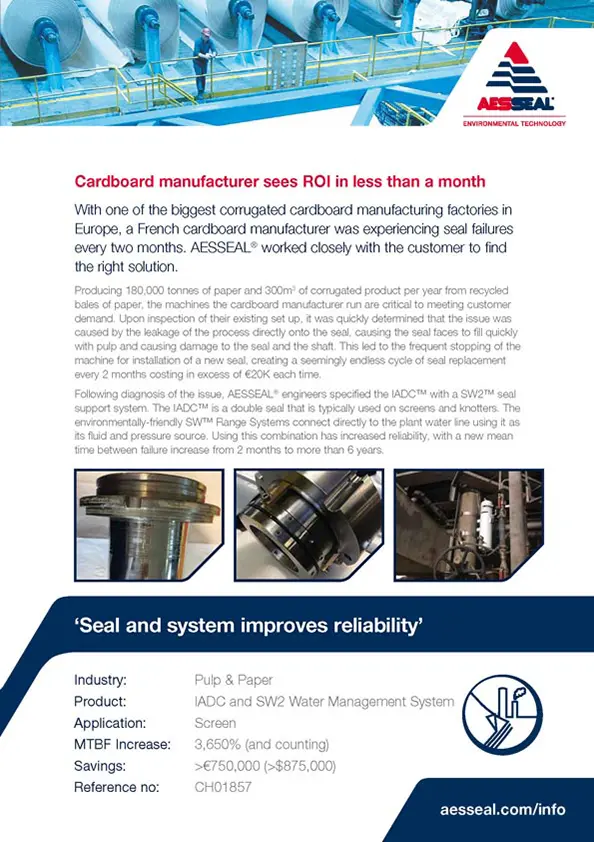

ROI In Less Than A Month

Chemical Producer Saves Over £1.7 Million in Plant Downtime

Upgrade will result in major savings for US company

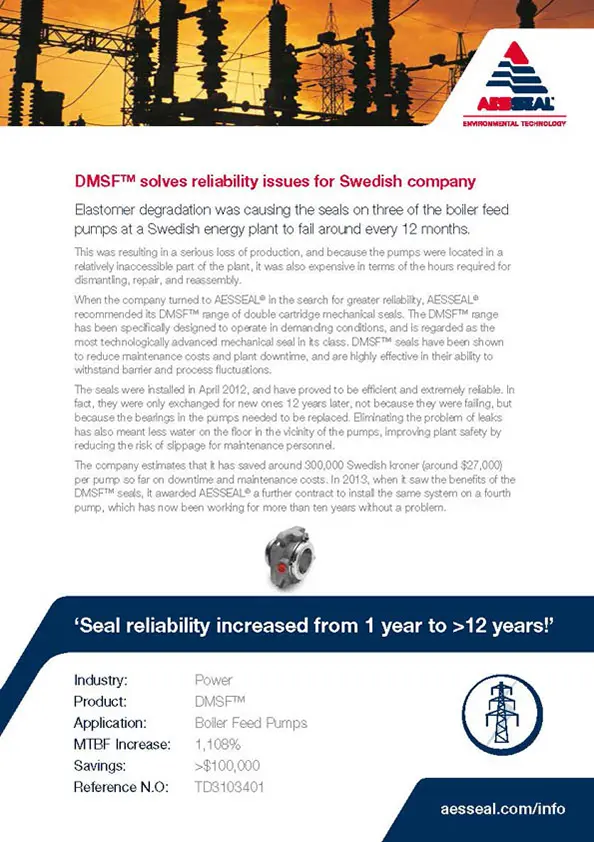

DMSF solves reliability issues for Swedish company

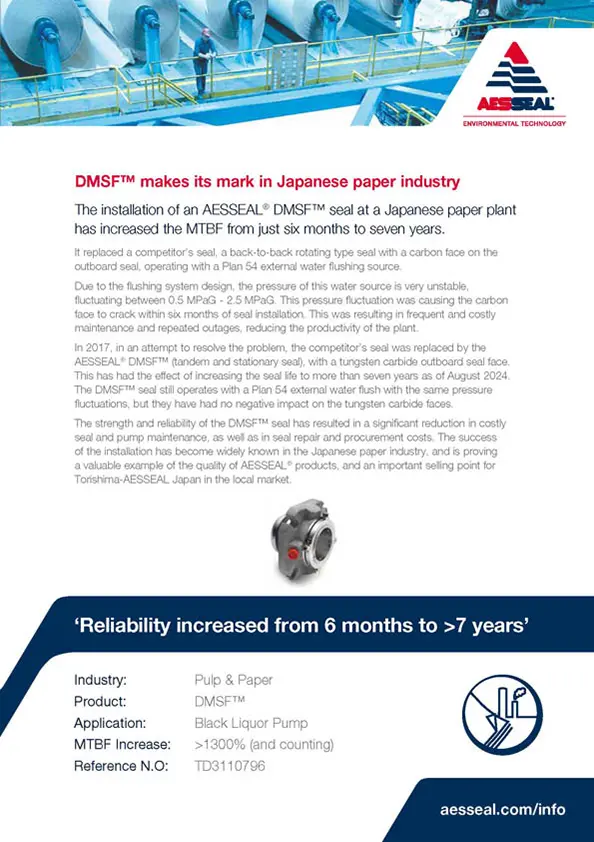

DMSF makes its mark in Japanese paper industry

AESSEAL helps UK firm to multi-million pound savings

CDPH & EasyClean boosts MTBF from four months to seven years

Full steam ahead for refinery after change to STS seals

DMSF seals end contamination problem for Spanish firm

Huge savings after LabTecta installation

DMSC saves Nestlé Purina £182k in just 10 months

AESSEAL product stops hot oil pump leakage

LabTecta saves €360,000 for Spanish company each year

Major savings for Algerian food producer

Mechanical seals runs an incredible 17 years without problems

Exceptional service saves thousands in lost revenue

AESSEAL were contacted by a power plant in the UK who were experiencing a major issue with their supply of mechanical seals.

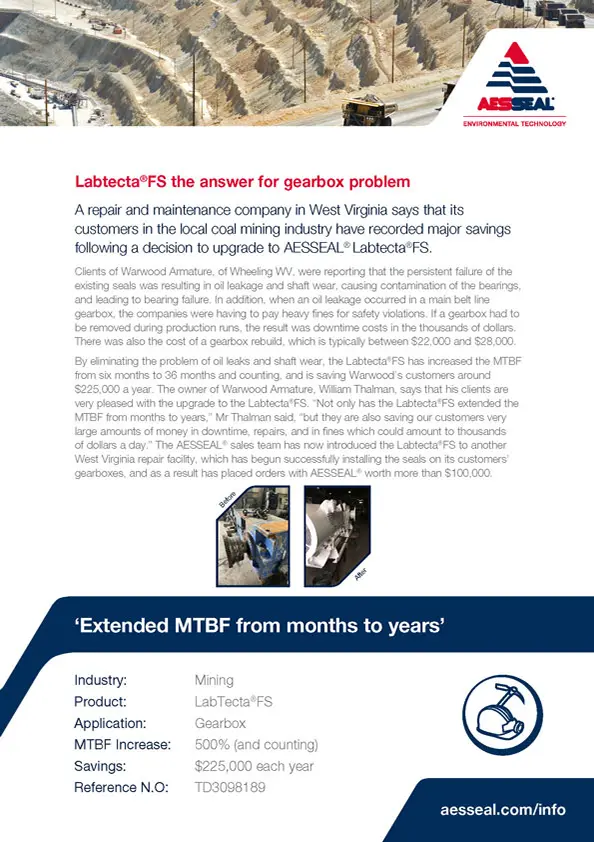

LabTecta FS the answer for gearbox problem