Recommended Products in this Industry

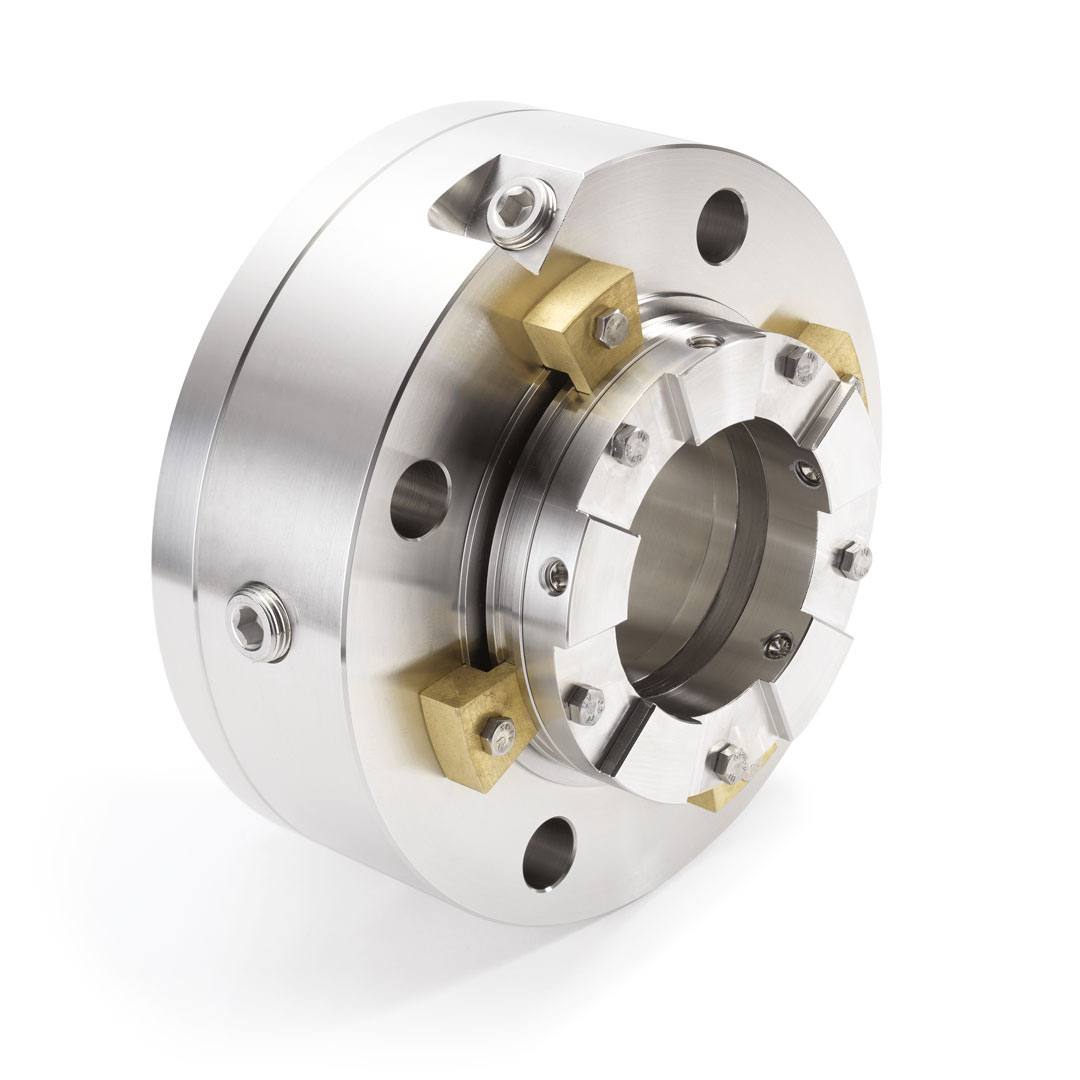

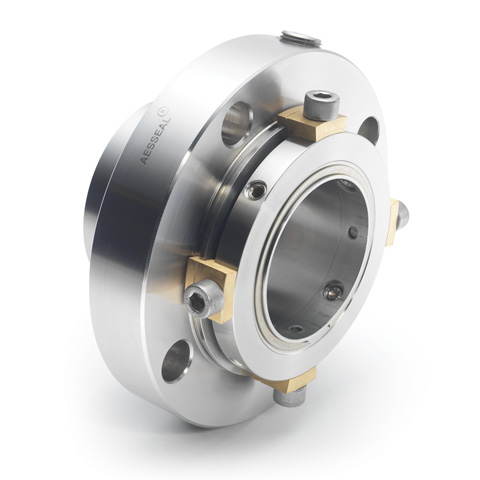

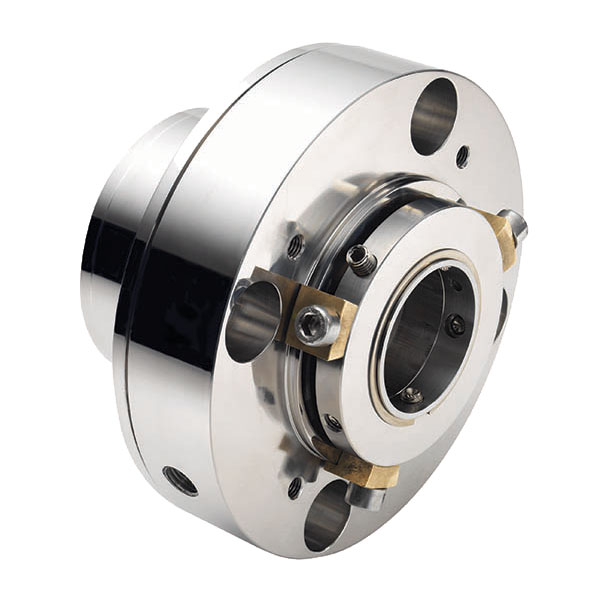

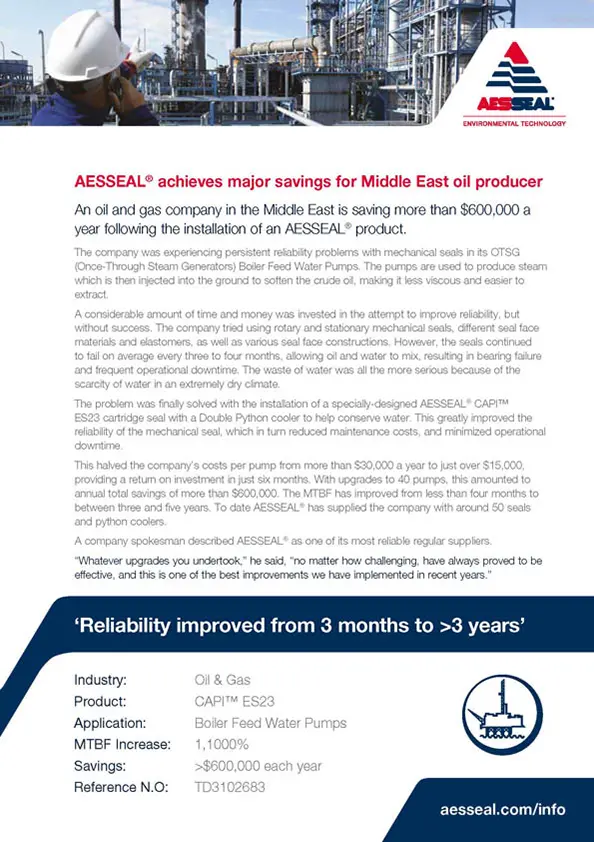

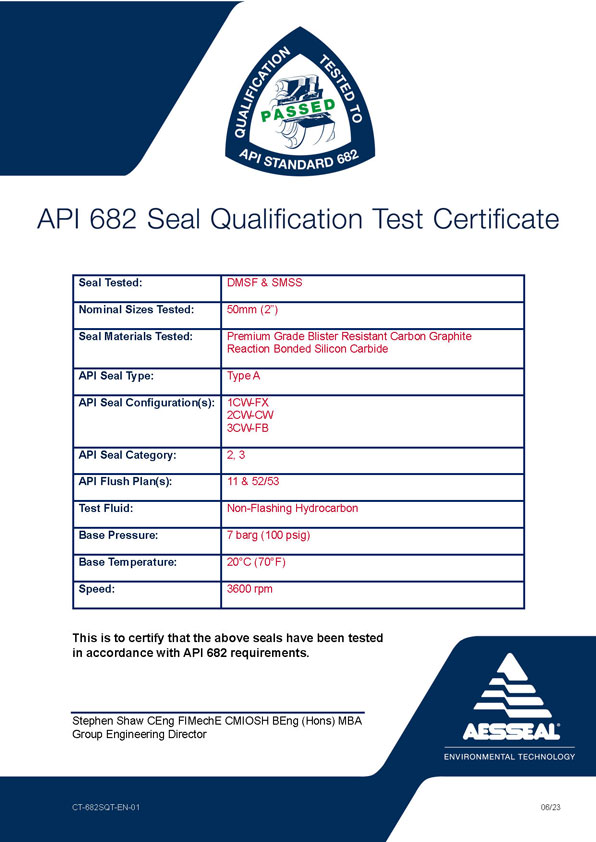

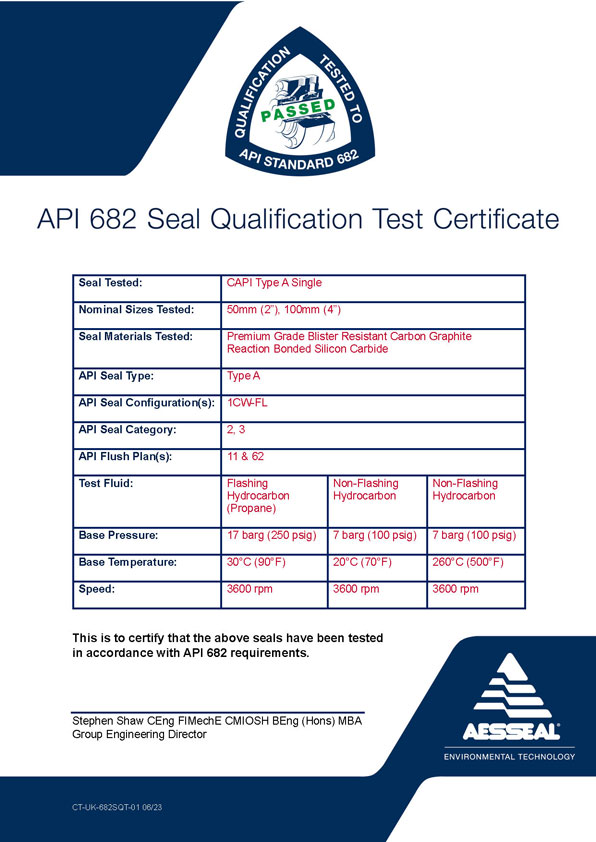

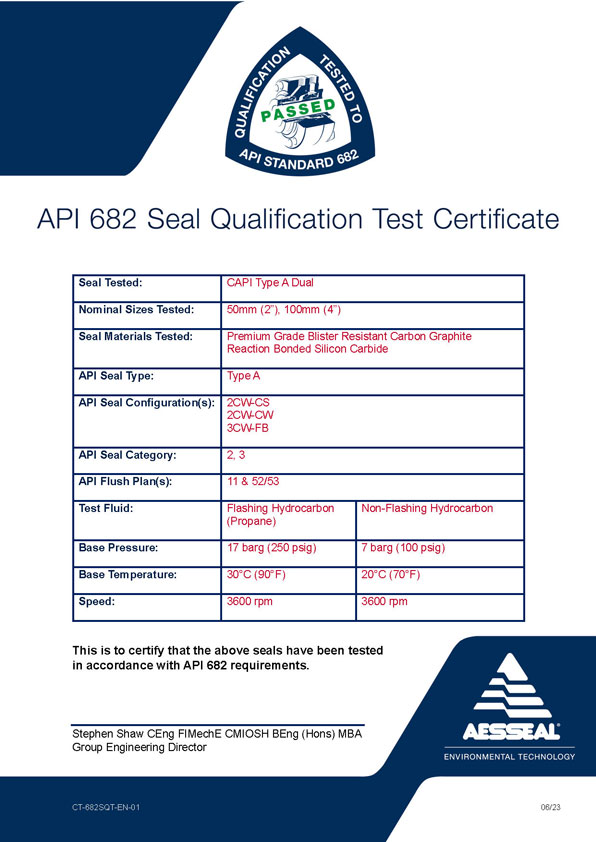

AESSEAL® have been providing API 682 compliant sealing solution to both end users and EPC companies in the oil and gas industry for many years.

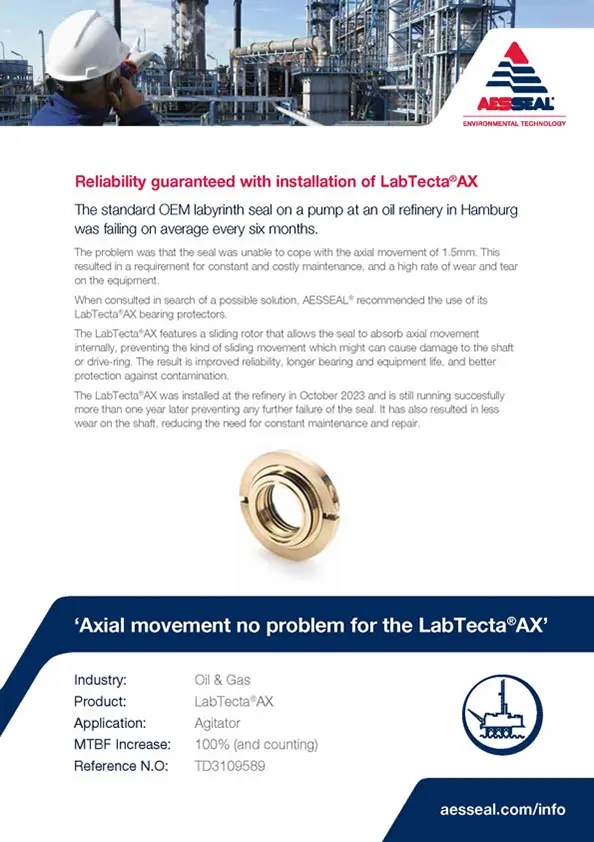

The solutions deliver improved reliability supported by one of the best customer service records in the industry.

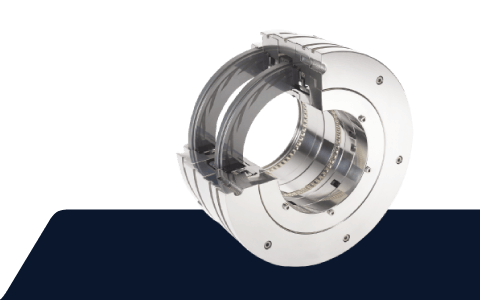

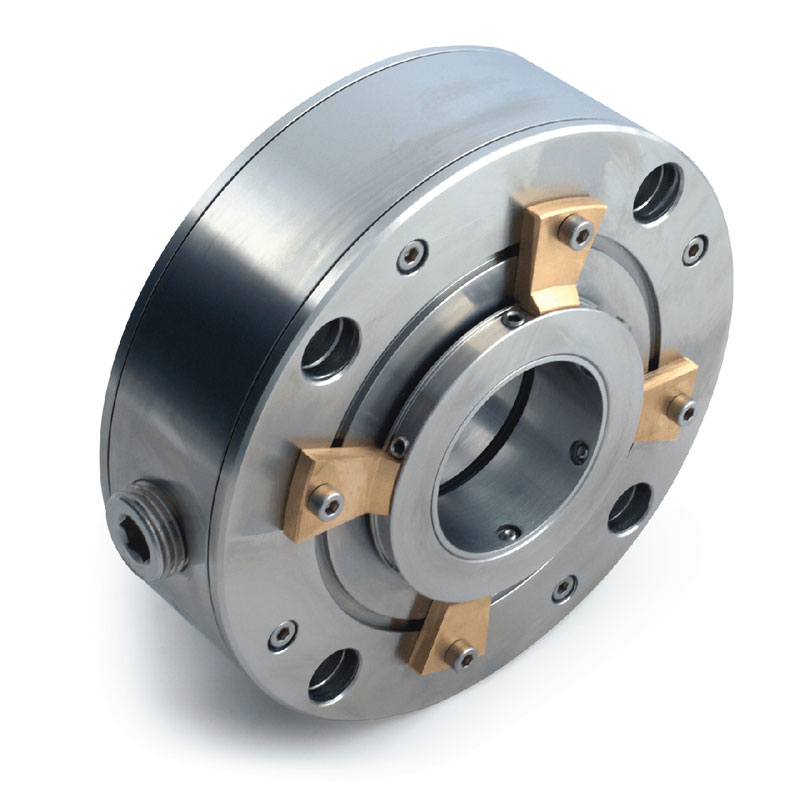

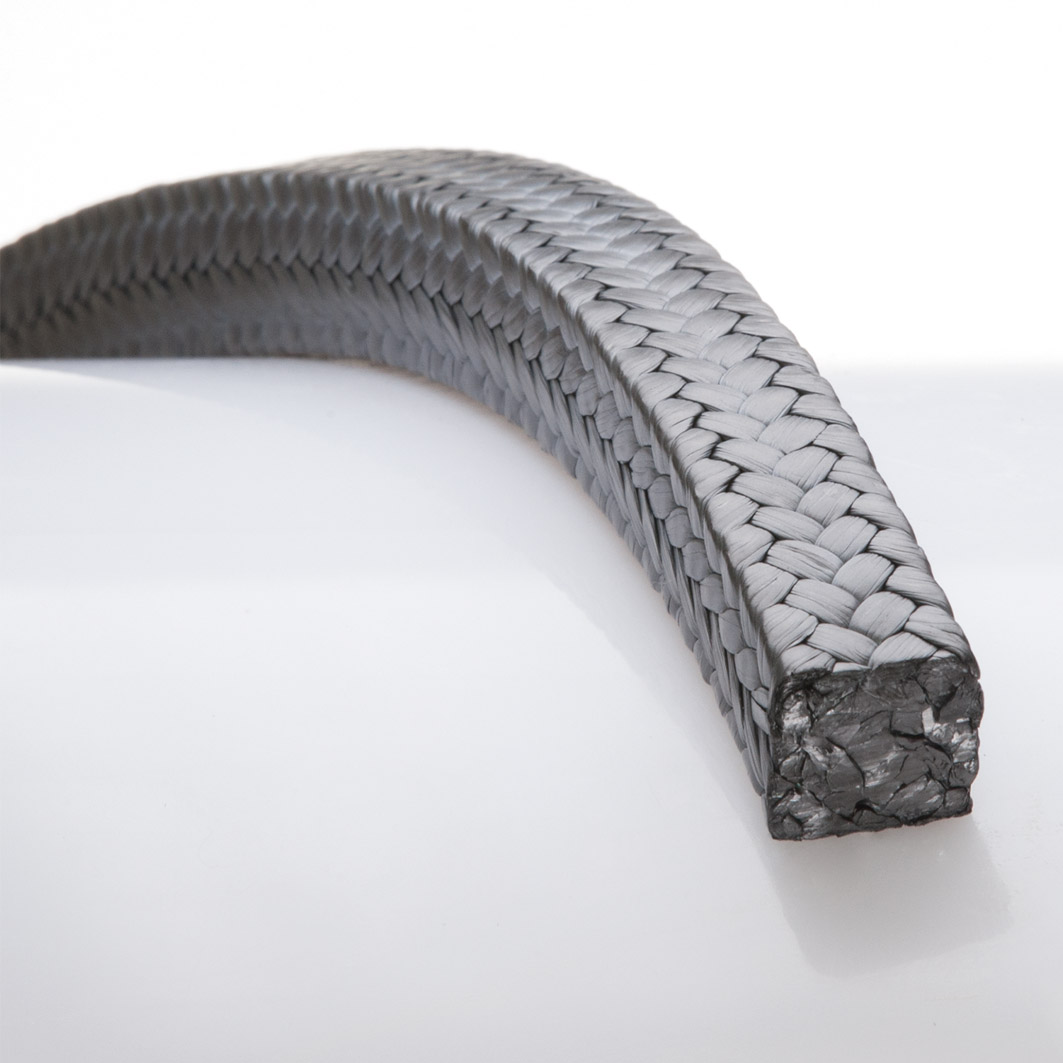

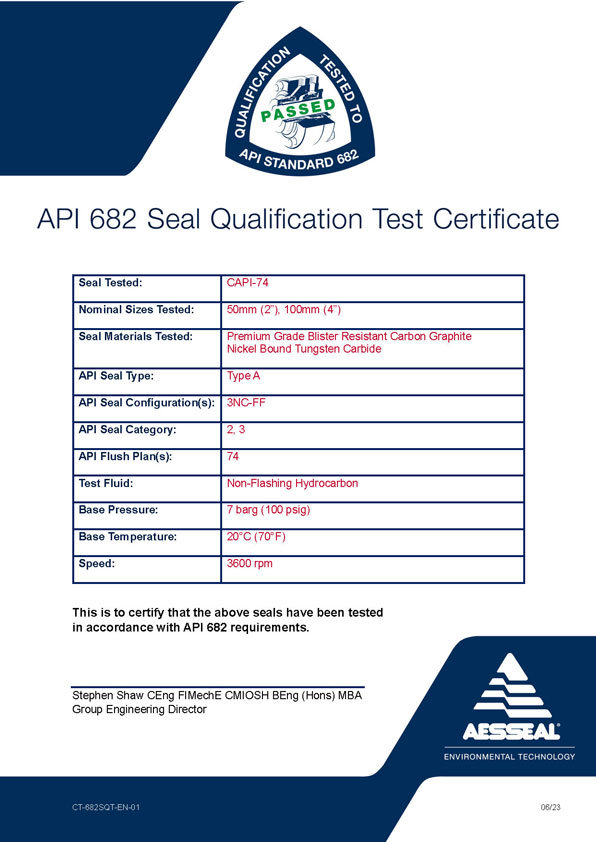

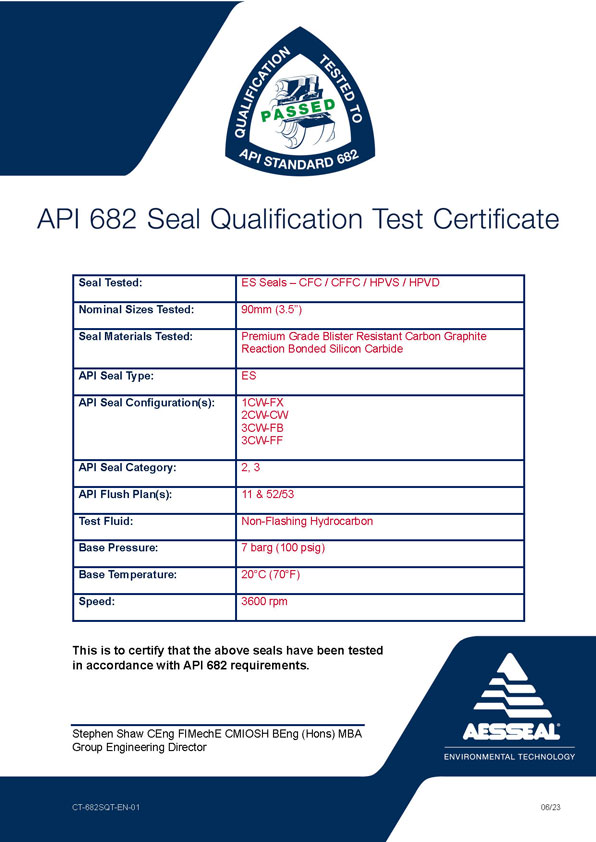

The CAPI™ range of seals is designed specifically for the oil and gas industry and design exist for many of the hundreds of pumps found. The unique CAPI-TXS range is designed to allow installation of dual seals in legacy pumps with smaller stuffing boxes, improving safety and reducing fugitive emissions without the need to modify the pump.

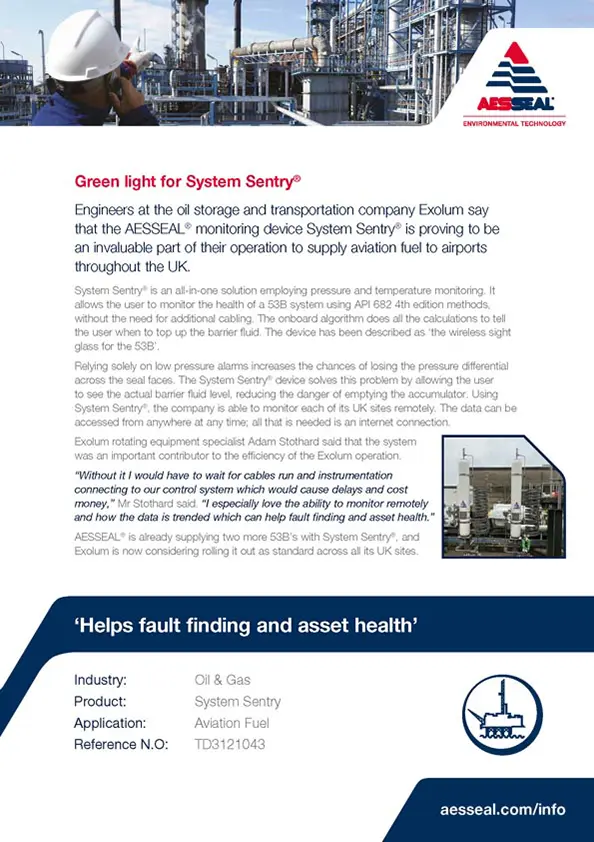

AESSEAL® offer a range of seal support systems suitable for use in the oil and gas industry. Our compression fit API53B system is particularly popular offering a range of options including the Python cooler, which offers superior cooling without the need for plant utility services. The modular construction ensures market leading product lead times.

API Plans

We have seal support solutions available for all API Piping Plans; Our API Piping Plan documentation show widely used standardized flushing piping arrangements.

Get access to the industry brochures

Industry Solutions

Downstream

Downstream is a term commonly used to refer to the refining of crude oil and the selling and distribution of natural gas and products derived from crude oil. As many as 2,300 different products can be processed through a refinery. Typically the refined products are used in:

- Fuels for vehicles

- Fuels for the generation of heat and power

- Raw materials for the petrochemical and chemical industries

- Speciality products such as lubricating oils, paraffin, waxes and bitumen

- Energy

Variation in product type, the available crude quality and requirements set by authorities mean that no two refineries are the same. To meet your specific needs the modular nature of our inventory means that we can quickly adapt our range to the application requirements of each refinery.

Petro Chemical

The petrochemical industry transforms crude oil and natural gas into products and raw materials. Petrochemical plants use the by-products from the refining process to produce every day products such as plastics, ethylene and fertilizers.

Due to the vast number of products produced by this industry there are many different plants and production processes. Whatever your processes, AESSEAL® prides itself on providing increased reliability solutions.

Upstream

Upstream is a term commonly used to refer to the search for, and recovery and production of, crude oil and natural gas. The sector is also known as the exploration and production (E&P) sector.