Fast Delivery Case Studies

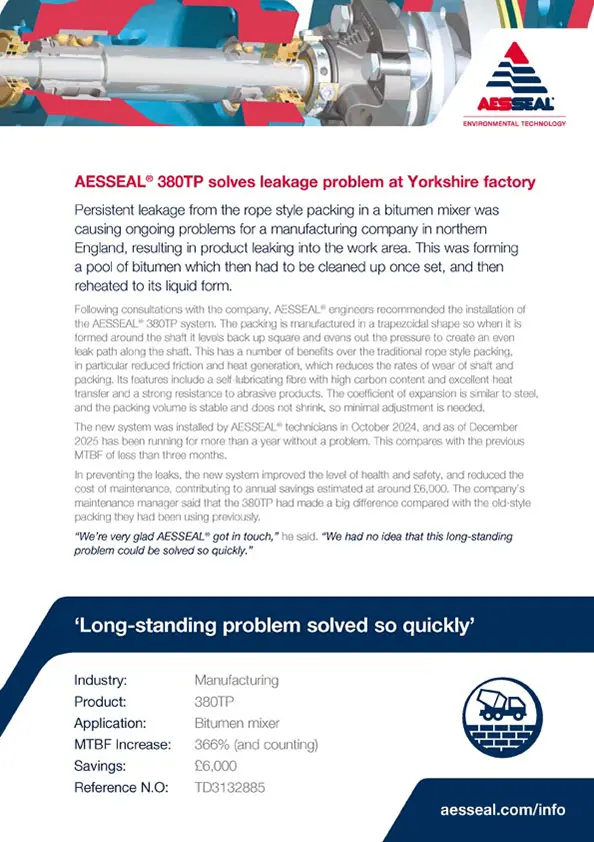

AESSEAL 380TP solves leakage problem at Yorkshire factory

Rapid response saves the day for UK company

AESSEAL quick response cuts delivery times

Fast response the key in Polish contract

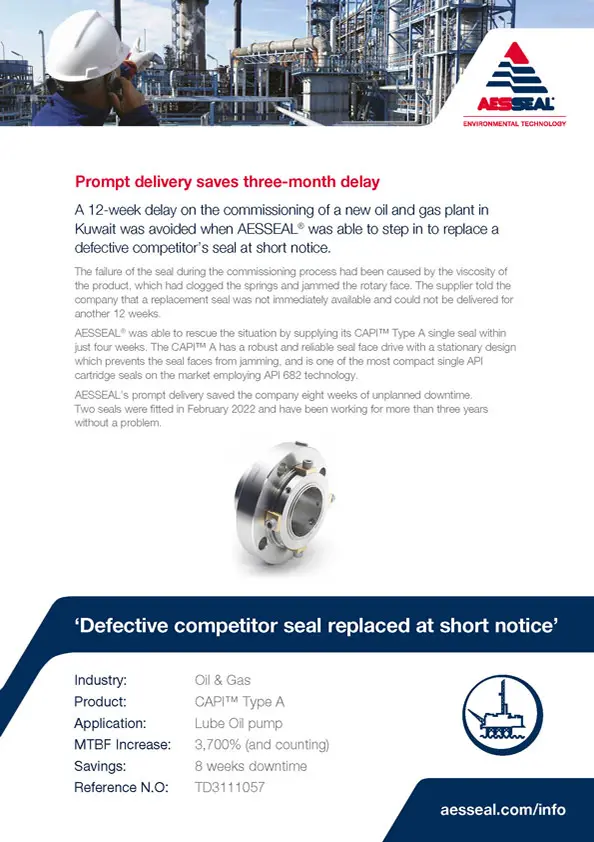

Prompt delivery saves three-month delay

Rapid response impresses Saudi customer

Sourced and supplied a replacement seal in just two weeks for customer’s Oil and Gas operation in Saudi Arabi

CURC solves reliability problem for SA company

Style 343 a lasting solution for Gulf power company

Problems with gland packing prompted a power and desalination plant in the Middle East to turn to AESSEAL.

Improved reliability for Flygt pump

A water utility company in the United Arab Emirates were dissatisfied with the performance of the mechanical seals in its Flygt pump.

Exceptional service saves thousands in lost revenue

AESSEAL were contacted by a power plant in the UK who were experiencing a major issue with their supply of mechanical seals.

STS steam seal updates UK Ethylene plant

UK oil refinery close to shutting down following labyrinth seal failure

New approach for slurry pumps reduces water usage by 95%

Price and lead time more than halved

Fast delivery, reliable solutions.

Quality of service key to AESSEAL contract

Eliminating over 61 million gallons of water from 26 evaporator pumps

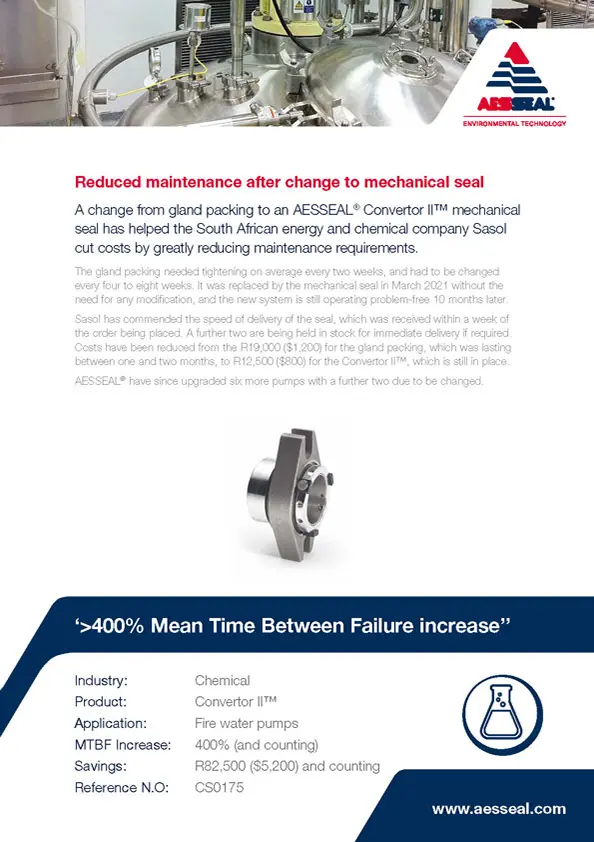

Reduced maintenance after change to mechanical seal

Reliability upgrade saves over ZAR200,000 in just 10 months of operation

Reliable solution for high pressure, high temperature agitator application

Navy reduces repair times and improves pump reliability

Chemical Producer Saves Over £1.7 Million in Plant Downtime

Unbeatable lead times on bearing protection