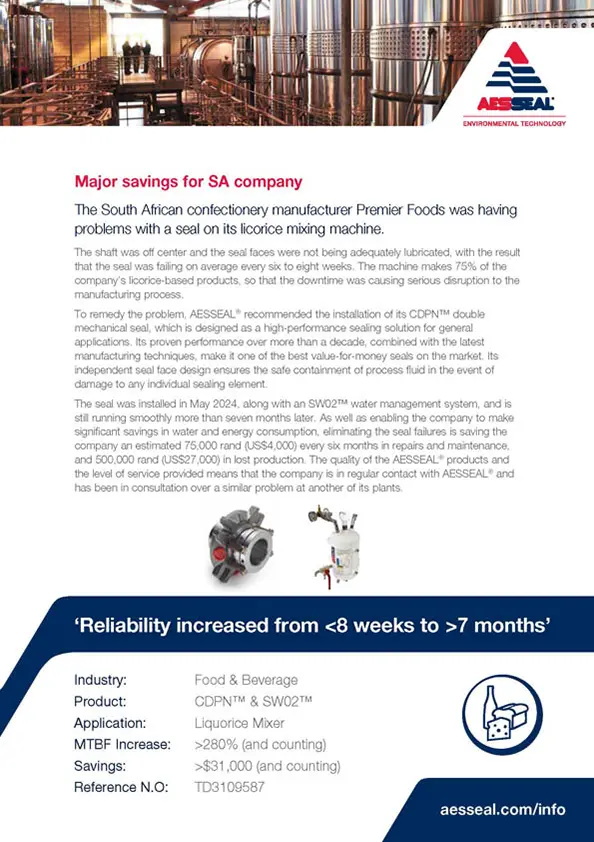

The South African confectionery manufacturer Premier Foods was having problems with a seal on its licorice mixing machine.

SA firm makes big savings with CDPN

Constant seal failures followed by downtime and loss of production were causing problems for the South African company Woodchem SA.

Major savings for SA company

A South African coal mining company is making significant savings following a decision to send its CDPH heavy duty slurry seals directly to AESSEAL for reconditioning.

DMSF seal the answer at South African plant

The installation of the AESSEAL DMSF seal and SW2 water management system at the Ford plant in Pretoria, South Africa, has improved the MTBF of a crucial seal from less than two weeks to more than two years.

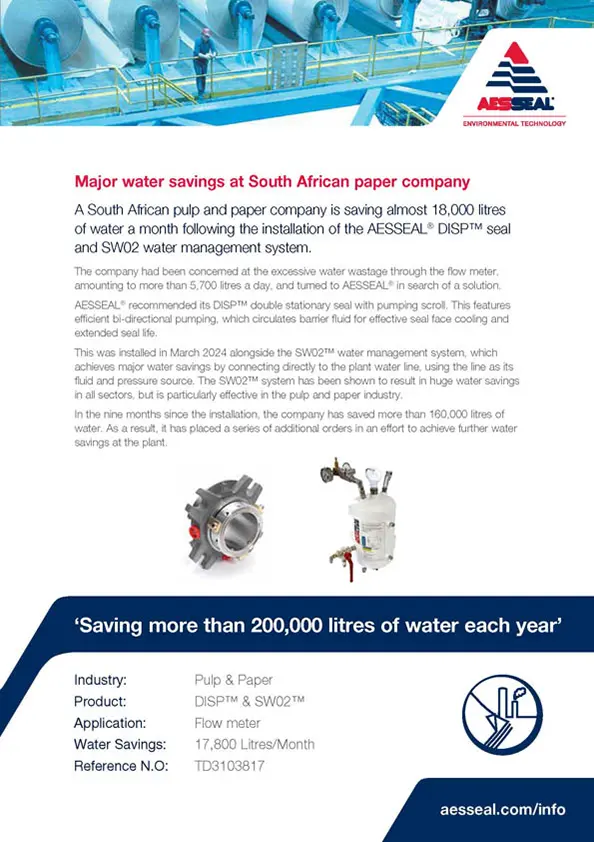

Major water savings at South African paper company

A South African pulp and paper company is saving almost 18,000 litres of water a month following the installation of the AESSEAL DISP seal and SW02 water management system.

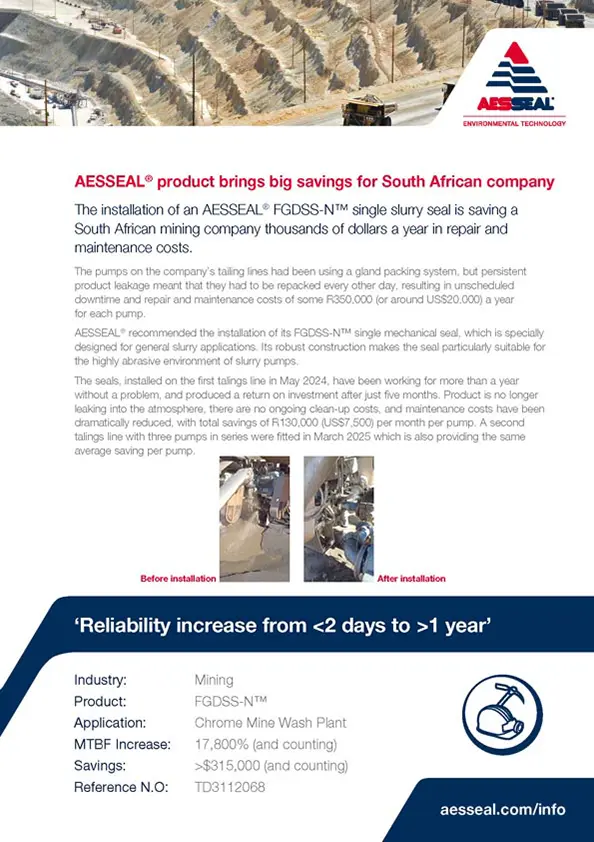

AESSEAL product brings big savings for South African company

The installation of an AESSEAL FGDSS-N single slurry seal is saving a South African mining company thousands of dollars a year in repair and maintenance costs.

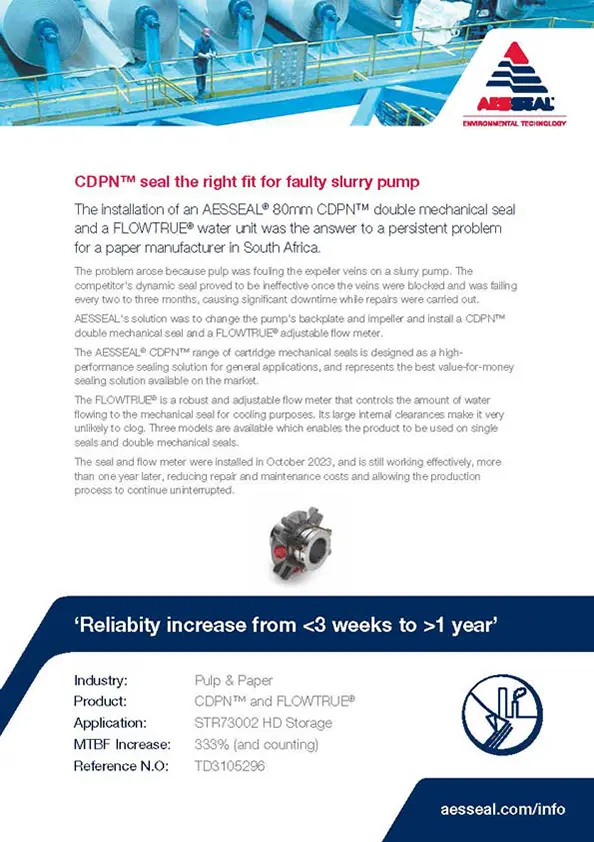

CDPN seal the right fit for faulty slurry pump

The installation of an AESSEAL® 80mm CDPN™ double mechanical seal and a FLOWTRUE® water unit was the answer to a persistent problem for a paper manufacturer in South Africa.

Major reliability improvement with CSSN seals

Installation of CSSN cartridge seal has resulted in a dramatic improvement in seal reliability for a South African chemical company.

CURC solves reliability problem for SA company

The persistent failure of a competitor’s cartridge seal was causing problems for the chemical processing company Investchem in Johannesburg.

AESSEAL is always available to help when needed

A South African mining company was continually being forced to halt operations at one of its plants when a competitor’s seal persistently failed at start-up.

AESSEAL product solves seal failure problem

The installation of an SISR seal with Plan 62 was the solution to the persistent seal failures being experienced by a South African chemical company.

DMSF seals halt water leakage

Premature seal failure was causing barrier water and product leakage in a South African chemical plant. This necessitated a plant shutdown while the seal was changed.

Fast delivery, reliable solutions.

During start-up of a new plant in South Africa, the customer had repeated problems with a mechanical seal that repeatedly failed. With start-up of the plant imminent, the customer required a reliable solution delivered quickly.

Improving reliability and reducing product loss for sugar Refinery

A South African based sugar refining plant was using gland packing on two screened juice pumps and two mixed juice pumps with a quench to drain seal support system.

Cleaner plant with AESSEAL gland packing

Gland Packing Style 745TP has resulted in a cleaner environment for a South African chemical company.

LabTecta the answer for SA chemical company

Constant motor failures on cooling tower motors were plaguing a South African chemical company.

Quality of service key to AESSEAL contract

The rapid response of the team for a replacement seal led to the award of a new contract from a South African chemical company.

Reduced maintenance after change to mechanical seal

A change from gland packing to AESSEAL Convertor II™ mechanical seal has helped a South African energy and chemical company.

Reliability upgrade improves Mean Time Between Failure by 5 times

Major chemical company SASOL were experiencing premature seal failure on one of its process pumps.

Reliability upgrade improves Mean Time Between Failure from 1 week to 8 months.

Major chemical company SASOL were experiencing premature seal failure on one of its process pumps.

LabTecta seals halt costly oil leaks

A South African company specialising in the production of animal feed was having constant problems with a leaking gearbox

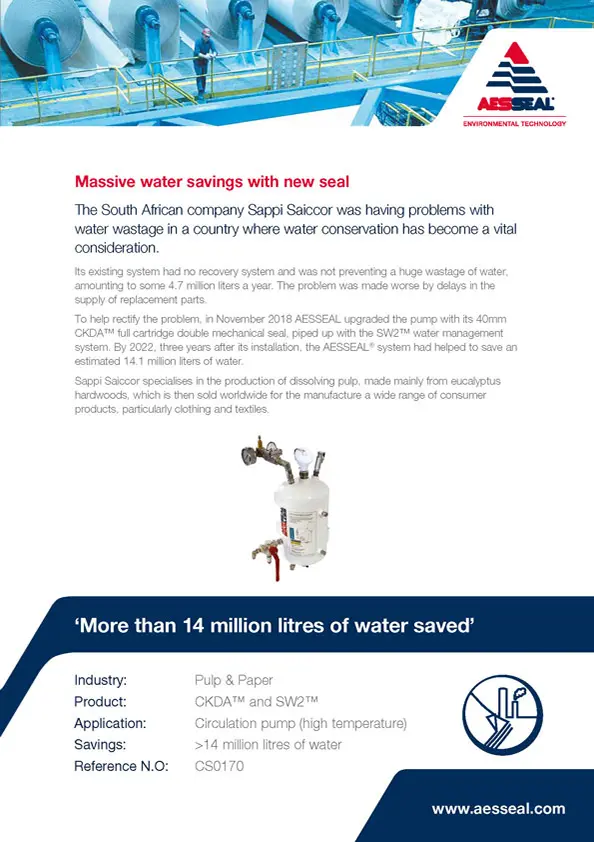

Massive water savings with new seal

The South African company Sappi Saiccor was having problems with water wastage.

Quality service and technical support for South African contract

lack of technical and service support led the South African company COFCO International to approach AESSEAL

A place of greater safety with AESSEAL SCMS

Shaft fretting and product leakage into the atmosphere were causing safety issues and problems of product contamination.

Trapezoidal Packing Improves Reliability

A paper producer in South Africa was having problems with packing on pumps leaking and damaging the pump shaft sleeve.

Water and cost savings with reliability upgrade

A beer producer in South Africa was being forced by the local government to save water around their facility.

ZAR84,000 Saving with reliability upgrade from packing

A vertically integrated chemical and mining company had a poor mean time between failure (MTBF) on a water pump on one of its mining facilities in South Africa.

Five times improvement in reliability

Experiencing poor reliability a mining facility in South Africa, a vertically integrated chemical and mining company turned to AESSEAL for assistance.

Mechanical seals runs an incredible 17 years without problems

Tongaat Hullett Sugar were un happy with the amount of maintenance required on the sealing of one of its pumps.

Mechanical Seal upgrade improve reliability and saves more than ZAR 580,000

A specialist mining company used gland packing in the feed pumps at their tailing processing facility.

Reliability upgrade improves reliability 700%

A major steel producer in South Africa were experiencing unacceptable leakage and reliability with one of their lime slurry pumps.

Reliability upgrade saves over ZAR200,000 in just 10 months of operation

A copper, zinc and lead mine in South Africa was experiencing reliability issues with three mine de-watering pumps.

Trapeziodal Packing improves reliability 3-fold

A phosphates and phosphoric acid producer in South Africa was having problems with the packing on its phosphoric acid pumps.

Over 20 million litres of water saved in 5 years for just 2 pumps

A latex producer in South Africa was consuming a large quantity of water in API Plan 54 seal support systems (quench to drain) in 2 pumps.

Dual Seal Upgrade saves over 17 million litres of water

A major sugar manufacturer at one of its alcohol manufacturing sites were looking to reduce the amount of water consumed on 19 critical pumps at one of its sites in South Africa.

Catalogue of issues lead to failures on power station valves

A South African power station were experiencing regular outages leading to expensive downtime along with poor emission control and high energy losses.

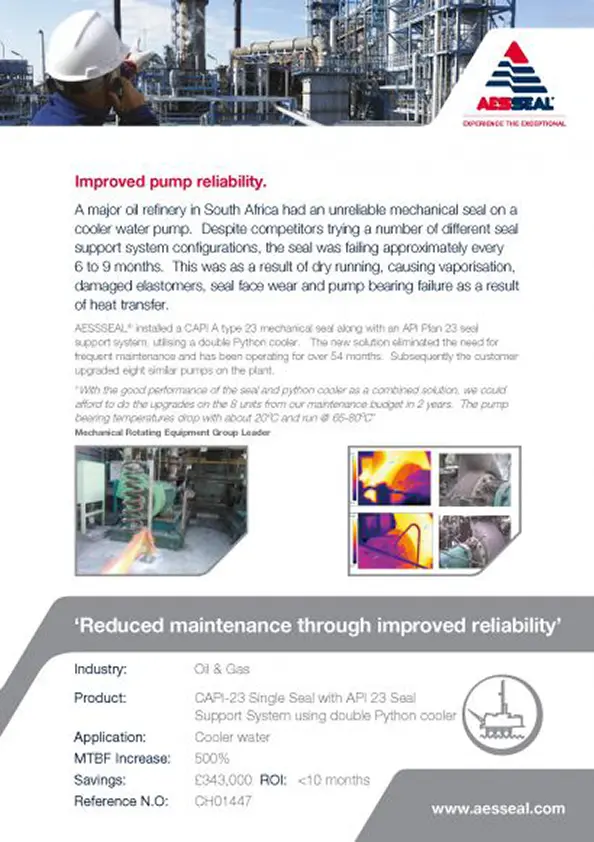

Improved pump reliability for oil refinery

A major oil refinery in South Africa had an unreliable mechanical seal on a cooler water pump. Despite competitors trying a number of different seal support system configurations, the seal was failing approximately every 6 to 9 months.

Huge Water Savings for Distillery

An alcohol distillation plant had historically used competitor single seals and previous engineers were not keen on the idea of changing to dual seals and systems.

Water Savings for South African Corn Miller

A South African corn miller had an evaportator pump that had poor reliability.

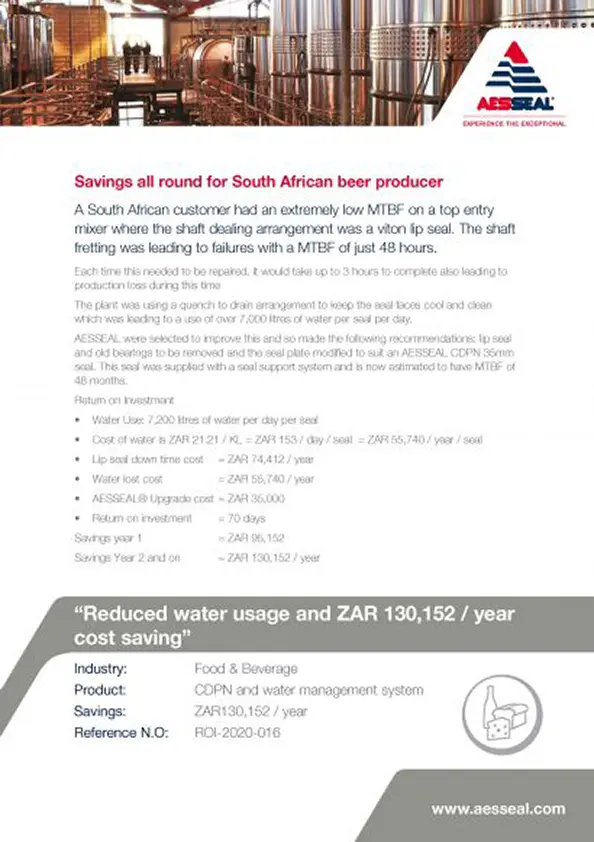

Savings all round for South African beer producer

A South African customer had an extremely low MTBF on a top entry mixer where the shaft dealing arrangement was a viton lip seal. The shaft fretting was leading to failures with a MTBF of just 48 hours.

Increased reliability saves over 1,500,000 ZAR

With an unreliable pump seal, major South African refinery turned to AESSEAL for assistance.

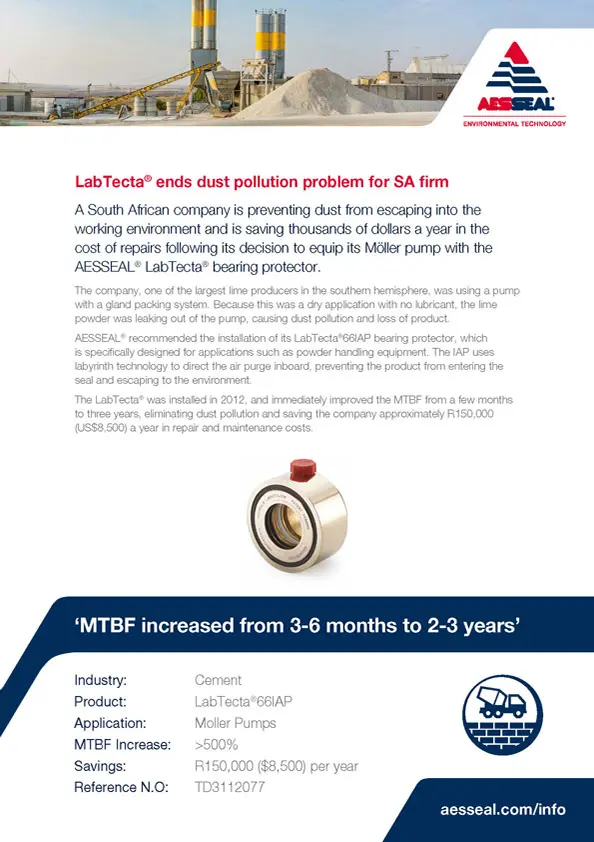

LabTecta ends dust pollution problem for SA firm

Preventing dust from escaping into the working environment and is saving thousands of dollars a year

Mondi Meets Sustainability Targets

AESSEAL water management systems cutting water usage at the plant by more than 60,000 kilolitres per month.

5 years without failure and a ZAR3.2million saving

Upgrade from gland packing to a CDPN seal increases MTBF despite pumping a highly abrasive mix of sand and seawater slurry.