Japan

LabTecta puts a stop to eight-year oil leaks

DMSF makes its mark in Japanese paper industry

Saudi Arabia

CURC solves leakage problem for Saudi company

Rapid response impresses Saudi customer

Sourced and supplied a replacement seal in just two weeks for customer’s Oil and Gas operation in Saudi Arabi

AESSEAL repair saves thousands for Saudi company

DMSF ends leakage problem for Saudi firm

Czechia

RDSX the answer for Czech chemical company

Egypt

Reliability Restored at Egyptian Sugar Refinery

Cairo company turns to LabTecta OP

The installation of the LabTecta OP bearing protection system at the Egyptian food production company NCMP (National Company for Maize Products) resulted in an immediate and dramatic improvement in reliability.

Ireland

Superior AESSEAL product and service seals the deal

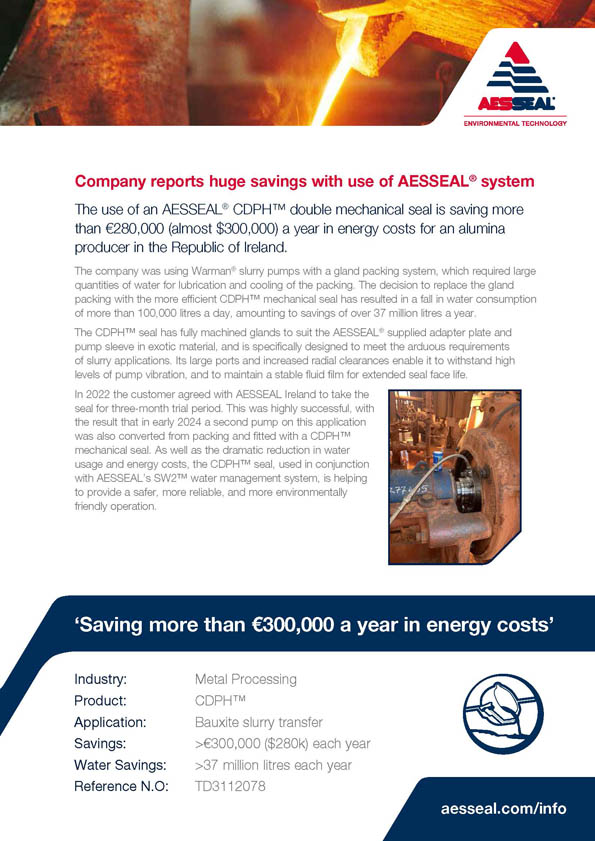

Company reports huge savings with use of AESSEAL system

CDSA makes for safer workplace

Upgrading component seals with M0FCA plug-in seals

One of the largest dairies in Ireland is upgrading from industry standard component type seals to AESSEAL M0FCA unitized plug-in seals after a successful 4 and a half year trial.

LabTecta upgrade increases MTBF rate by over 2000%

Botswana

AESSEAL quick response cuts delivery times

CDPH brings big savings for Botswana company

Saving over 1 billion gallons of water

Sweden

DMSF solves reliability issues for Swedish company

AESSEAL product improves reliability at Swedish plant

Swedish plant makes savings with DMSF

Major savings with CKD double seal

Kuwait

Prompt delivery saves three-month delay

Belgium

Lower balance temperature and correct alignment the key to longer seal life

STS seal and LabTecta ST ends steam leak hazard

Austria

Huge savings at Austrian steel mill

Italy

AESSEAL product removes risk of HFC emissions

Energy Savings for Italian Corn Miller

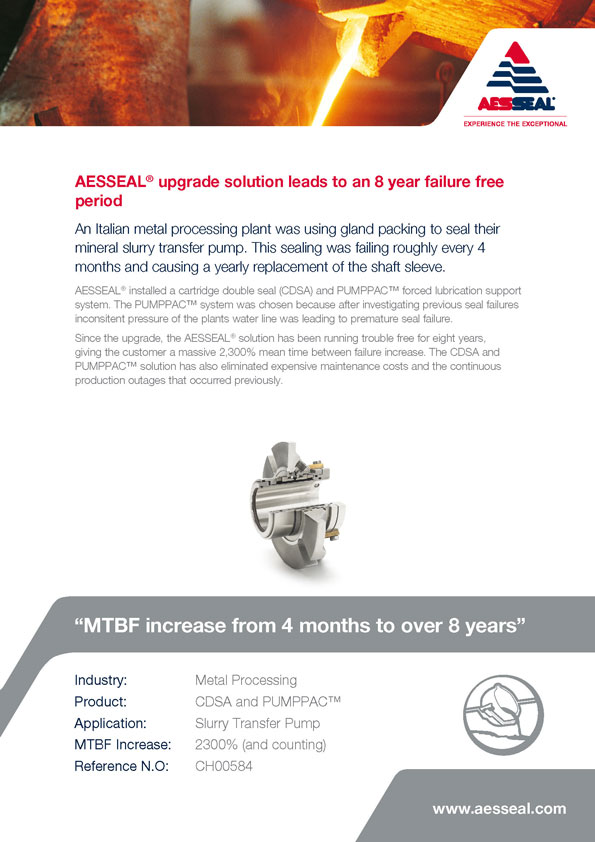

AESSEAL upgrade solution leads to an 8 year failure free period

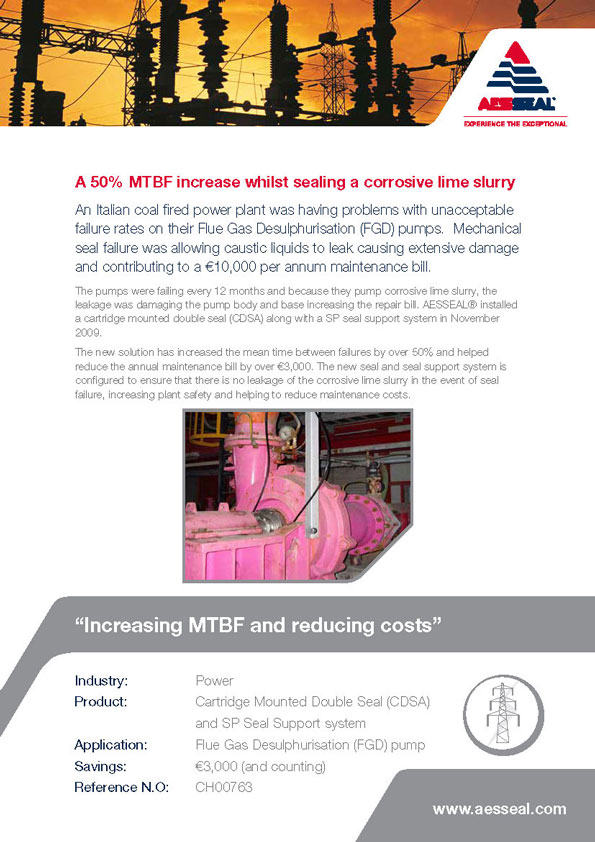

A 50% MTBF increase whilst sealing a corrosive lime slurry

AESSEAL help a Polyethylene plant save €144,000 in 30 months

Portugal

LabTecta reduces repair costs for Portuguese mining company

AESSEAL packing guarantees highest food quality

Denmark

CDPH & EasyClean boosts MTBF from four months to seven years

Improved reliability and reduced water consumption

Algeria

Major savings for Algerian food producer

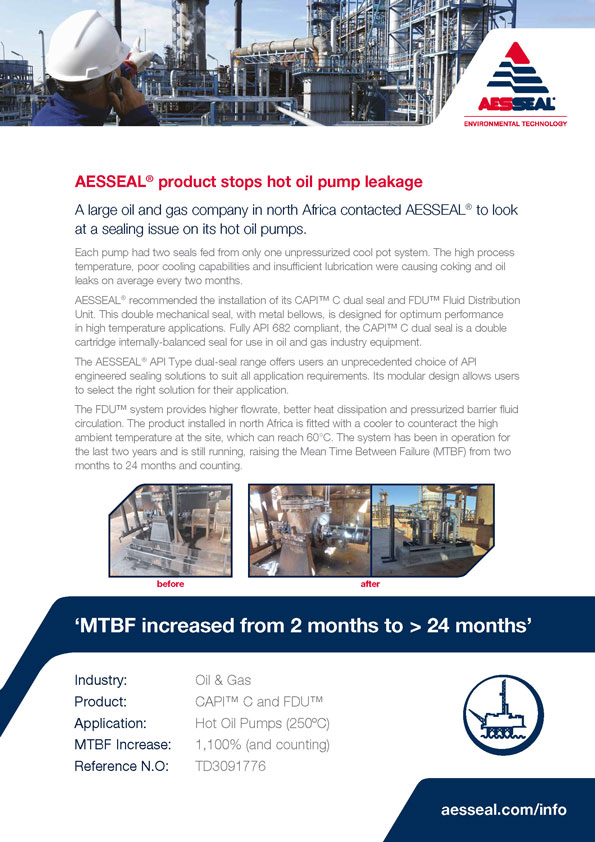

AESSEAL product stops hot oil pump leakage

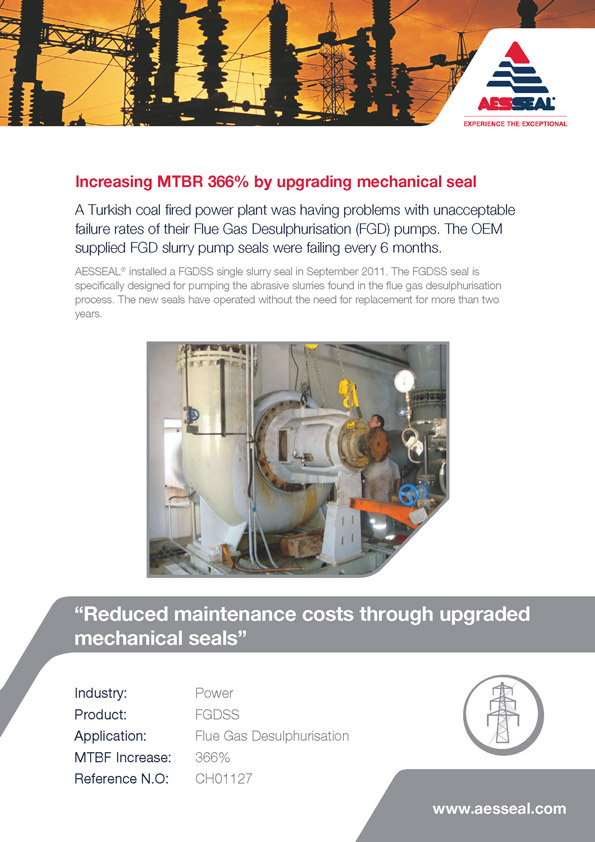

Türkiye

AESSEAL LabTecta the answer for Turkish company

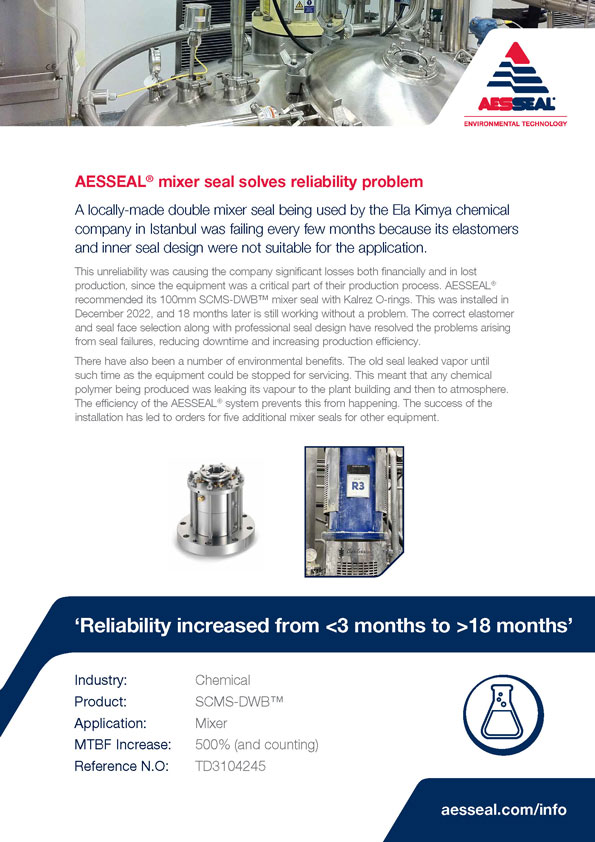

AESSEAL mixer seal solves reliability problem

A locally-made double mixer seal being used by the Ela Kimya chemical company in Istanbul was failing every few months because its elastomers and inner seal design were not suitable for the application.

Autoclave specialist chooses AESSEAL for reliability and customer service

A Turkish phosphate fertiliser was established following a requirement for Turkey to produce most its own phosphate fertiliser.

Increasing MTBR 366% by upgrading

Switzerland

Change to packing saves Swiss company $millions

A chocolate producer in Switzerland has saved around ₣2.3 million ($2.6 million) over the past year following its decision to change to an AESSEAL pump packing system.

Oman

AESSEAL achieves major savings for Middle East oil producer

An oil and gas company in the Middle East is saving more than $600,000 a year following the installation of an AESSEAL product.

Company makes huge savings with AESSEAL system

6 times improvement in MTBF for Upstream water injection pump

Qatar

Style 343 a lasting solution for Gulf power company

Problems with gland packing prompted a power and desalination plant in the Middle East to turn to AESSEAL® in search of a solution.

Seal upgrades save over US $3.4million in seven years

Seal upgrade improves pump availability

Finland

RDSX the seal of choice for Finnish company

Congo - Kinshasa

New approach for slurry pumps reduces water usage by 95%

Namibia

AESSEAL system eases cost pressures for African company

Huge water savings for uranium mine

South Korea

Salt water spray contamination eliminated by bearing protection

Brazil

Offshore oil and gas company calls in AESSEAL for bearing protection

India

LabTecta protection system extends bearing life

OEM Company praises AESSEAL design

New orders follow success of AESSEAL installation

Mexico

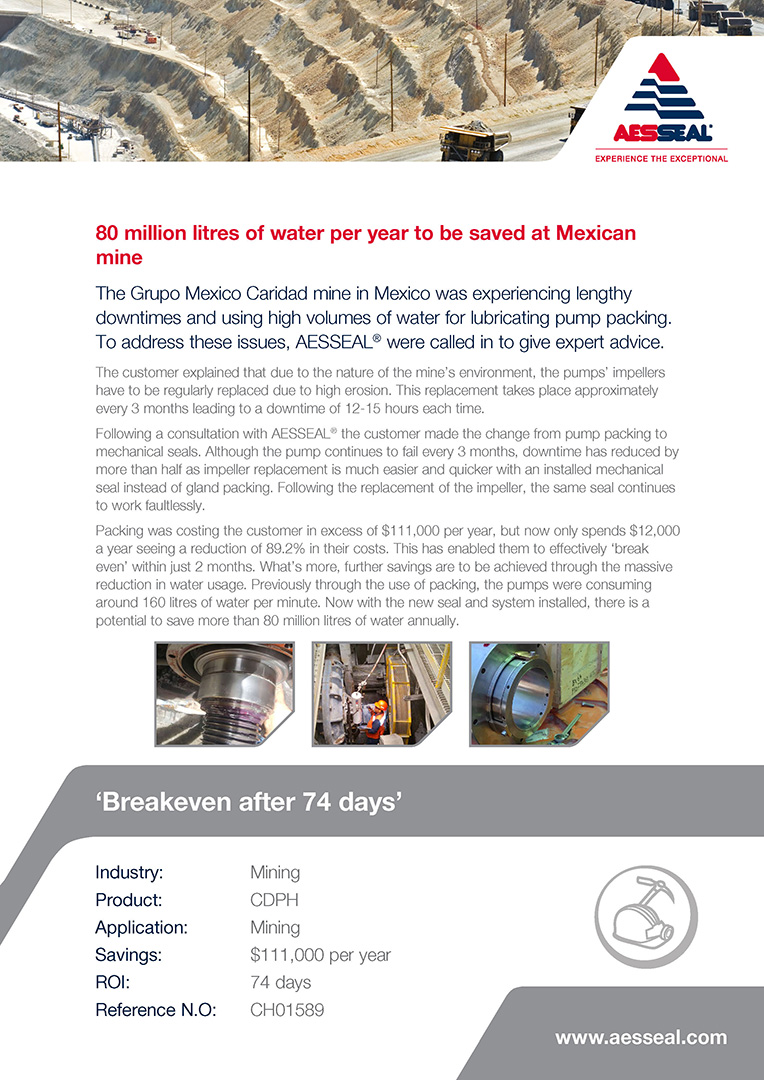

80 million litres of water per year to be saved at Mexican mine

Netherlands

Bearing protection increases mean time between failure

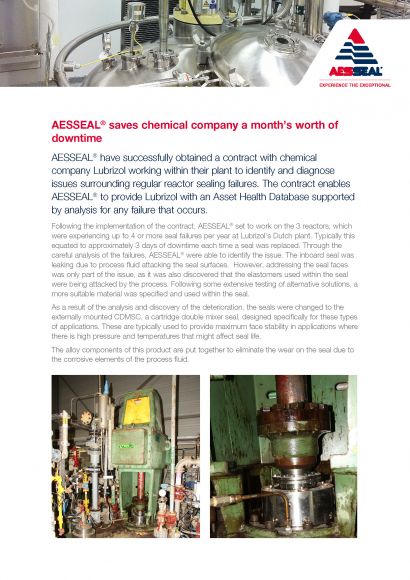

Chemical company saves a months worth of downtime

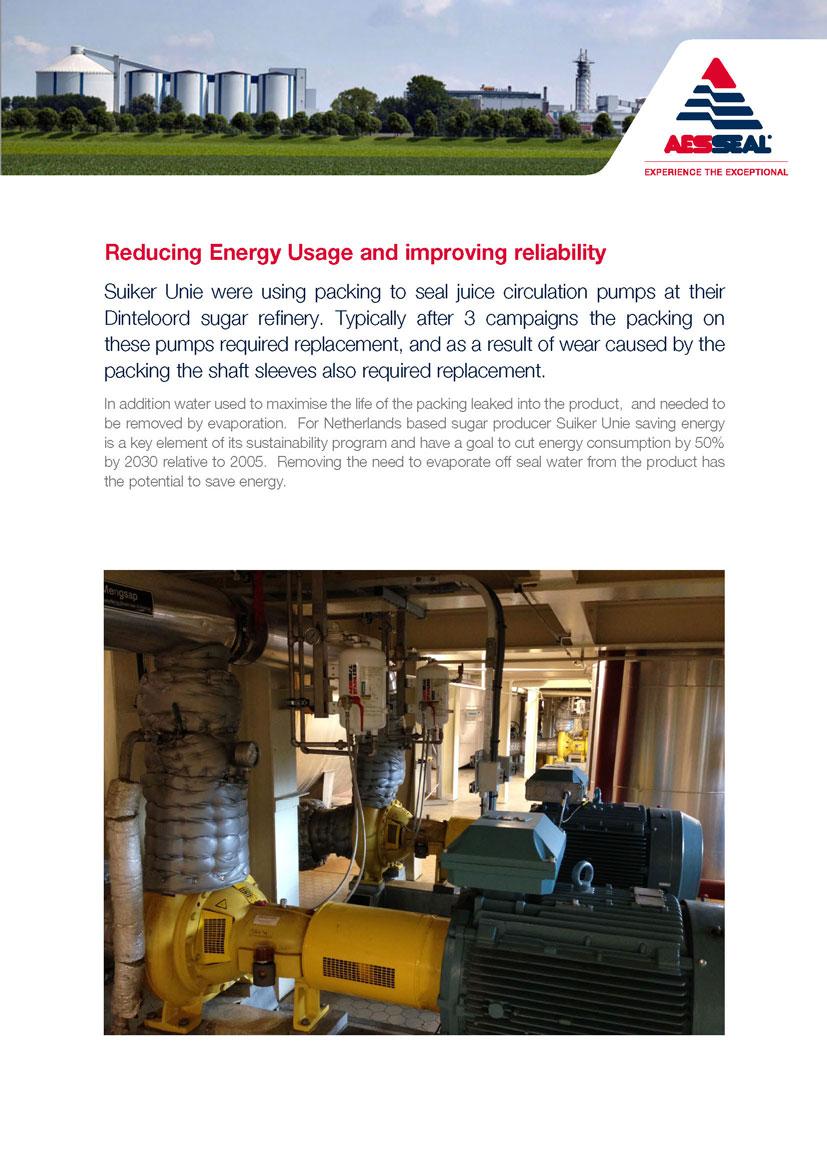

Reducing Energy Usage and Improving Reliability

Argentina

Bearings saved with LabTecta bearing protector

Malaysia

Eliminating unplanned maintenance with API Plan 32