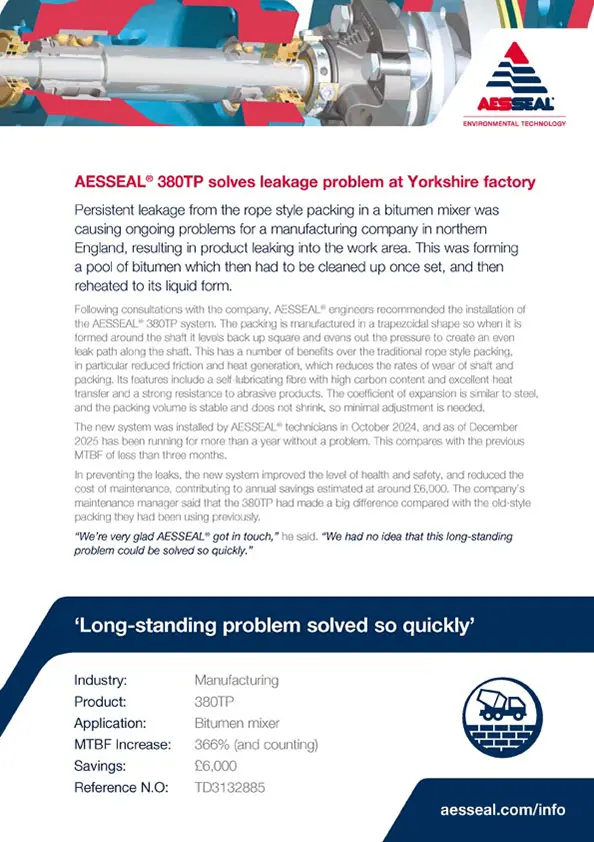

AESSEAL 380TP solves leakage problem at Yorkshire factory

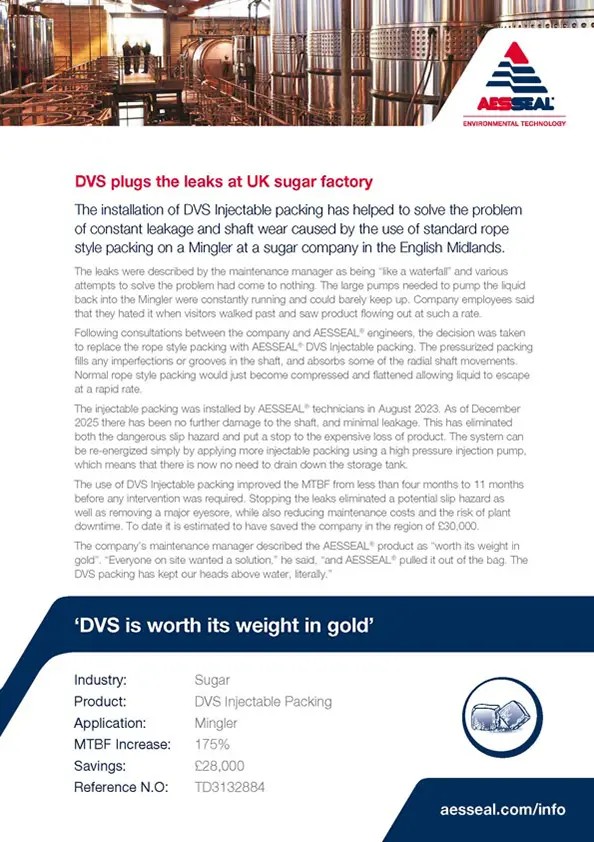

DVS plugs the leaks at UK sugar factory

Improved reliability with AESSEAL packing system

Green light for System Sentry

DVS Injectable packing solves leakage problem at Scottish plant

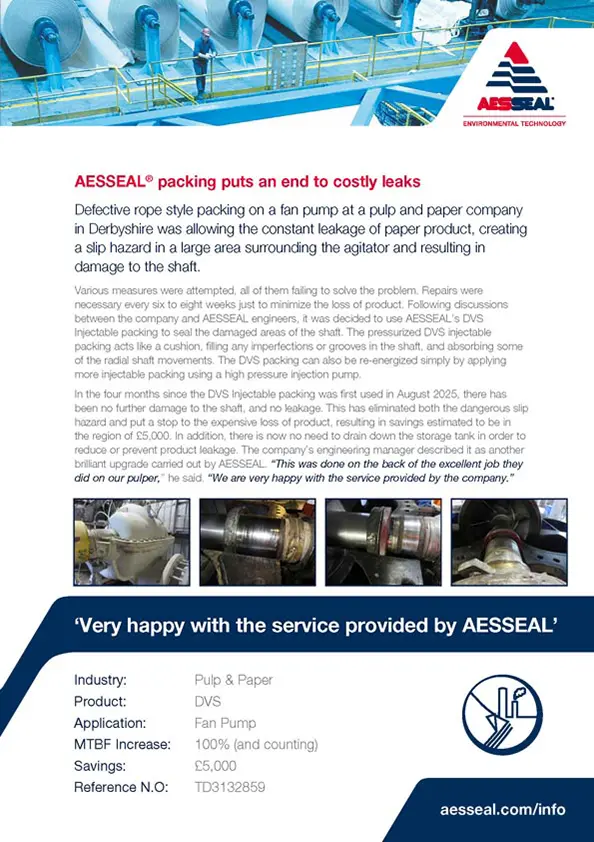

AESSEAL packing puts an end to costly leaks

AESSEAL cleans up the brown lagoon

A sugar company in the English Midlands has saved more than £40,000 following a decision to upgrade its packing system to the AESSEAL® trapezoidal cross-section packing AESSEAL® 380TP.

Rapid response saves the day for UK company

DVS saves thousands for UK firm

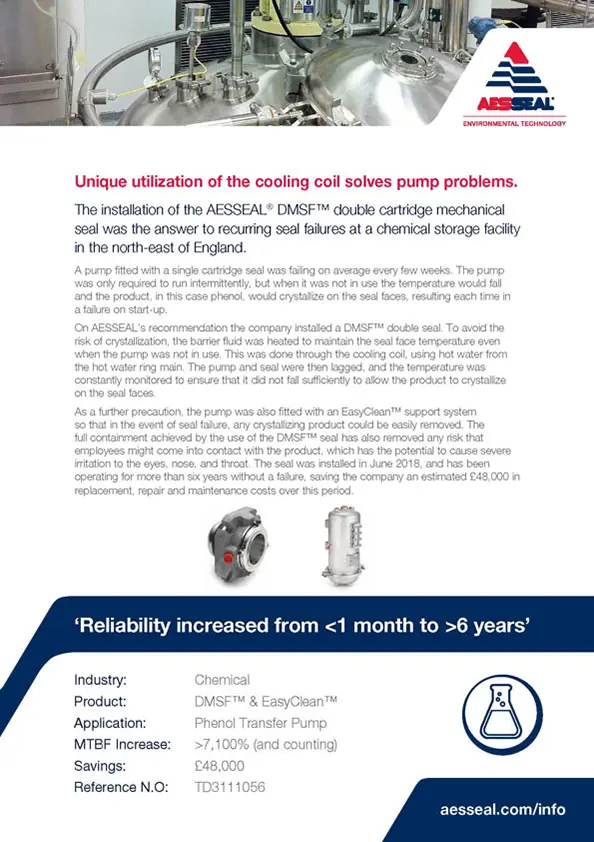

Unique utilization of the cooling coil solves pump problems.

CAPI-TXS the answer for legacy quench oil pumps

FIDC cleans up at salt plant

Staying cool in Cardiff

AESSEAL upgrade solves bearing failure problem

System Sentry proves its worth in INEOS field trial

Engineers at the petrochemicals manufacturer INEOS have given the seal of approval to the AESSEAL® monitoring device System Sentry® following a field trial at the company’s plant in Hull in the east of England.

CAPI dual seal ends slurry pump failures

The repeated failures of a single seal with an unreliable Plan 32 were causing a heavy-duty high head slurry pump at a South Wales steelworks to break down on average every three weeks.

AES-Elast the answer to seal selection problem

Employees at William Grant’s Scottish whisky distillery in Girvan, Ayshire, were having difficulty selecting the correct mechanical seals for specific applications.

LabTecta the remedy for lip seal failures

The lip seals in use at a north of England glass manufacturer were wearing out after just a few weeks

Bitumen pump upgrade saves over £23,000 a year

Asphalt producer pump for road surfaces was gland packed and losing over 15 tonnes of bitumen.

Standard of service makes AESSEAL a clear winner

The seal on a pump at a chemical plant in the east of England was burning out on average every two weeks due to dry running, resulting in some four hours of downtime each time it failed.

Exceptional service saves thousands in lost revenue

AESSEAL were contacted by a power plant in the UK who were experiencing a major issue with their supply of mechanical seals.

Improved Reliability for difficult application

A power plant in the UK were having frequent failures of the mechanical seal on a water circulating pump.

Sweet solution for sugar producer

Upgrade solves contamination problem

Leakage problem solved with STS

STS steam seal updates UK Ethylene plant

Huge savings after LabTecta installation

AESSEAL helps UK firm to multi-million pound savings

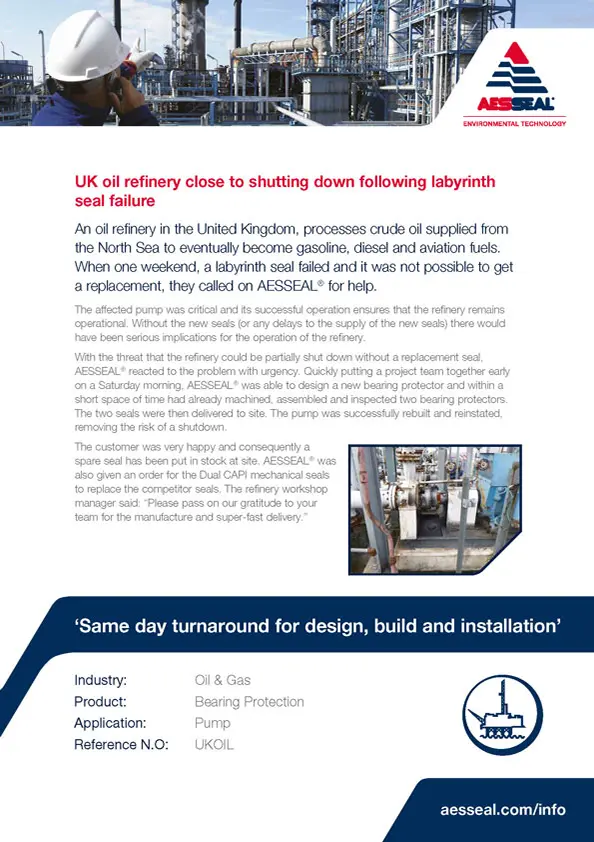

UK oil refinery close to shutting down following labyrinth seal failure

Full steam ahead for refinery after change to STS seals

LabTecta delivers reliability improvement

FDA compliant elastomer increases reliability

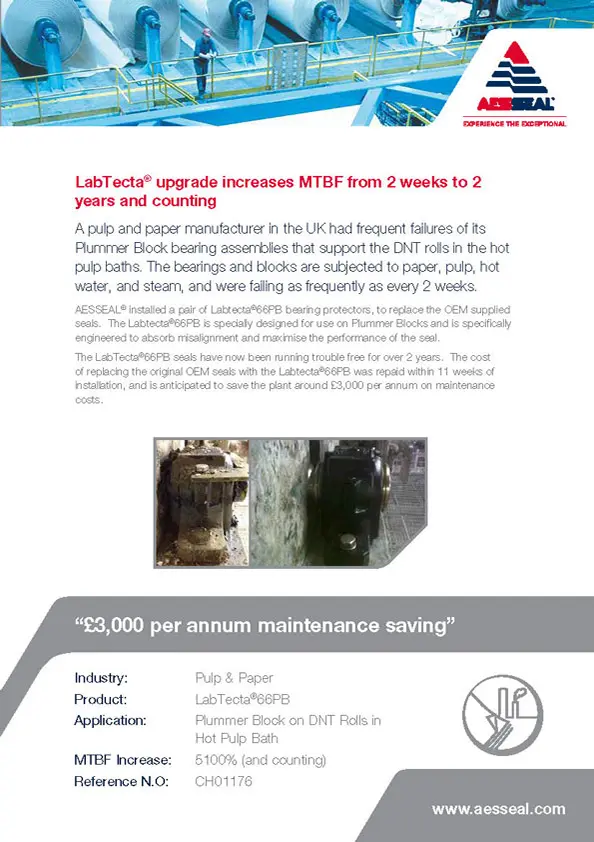

LabTecta upgrade increases MTBF from 2 weeks to 2 years and counting

Increased reliability with AESSEAL bearing protection

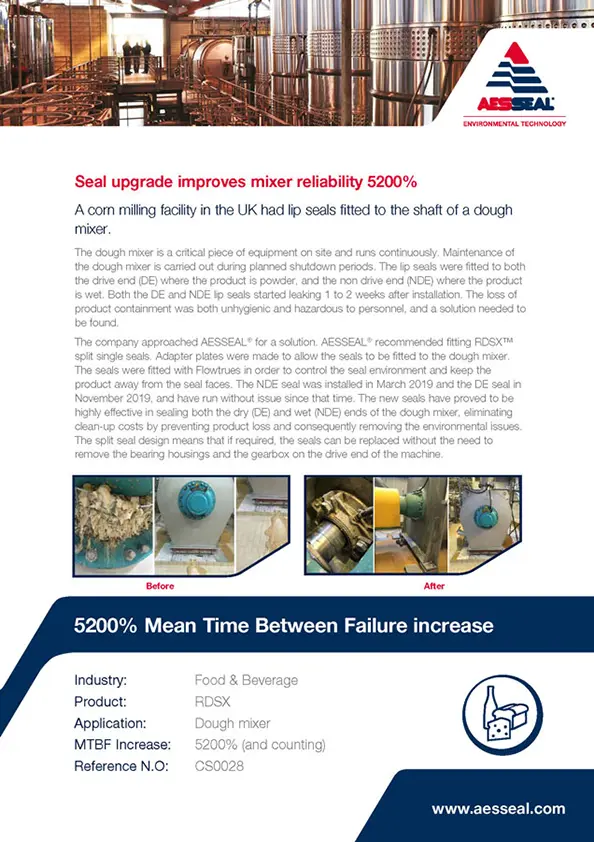

Seal upgrade improves mixer reliability 5200%

Reliability Improved For Waste Energy Company

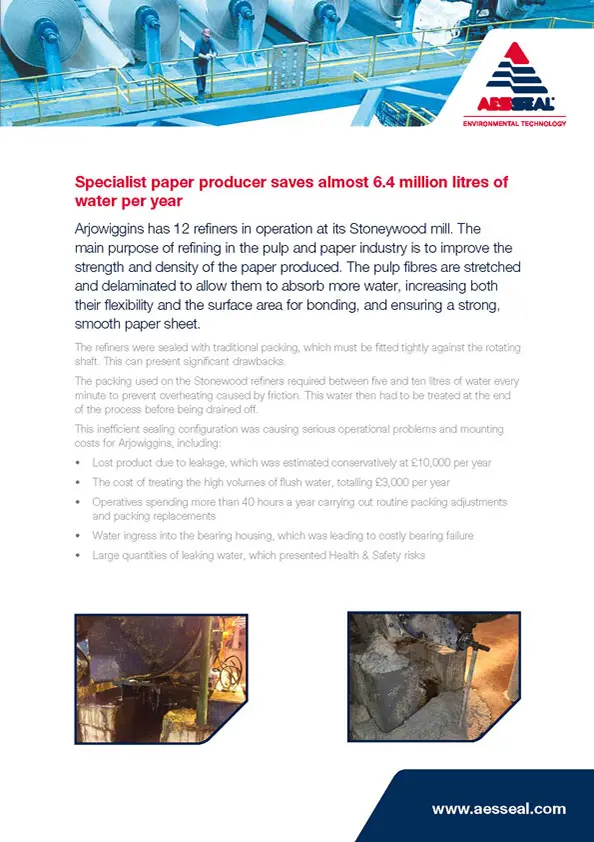

Specialist paper producer saves almost 6.4 million litres of water per year

Reliable solution for high pressure, high temperature agitator application

Navy reduces repair times and improves pump reliability

Mean time between failure doubles

Trialling different solutions to improve MTBF

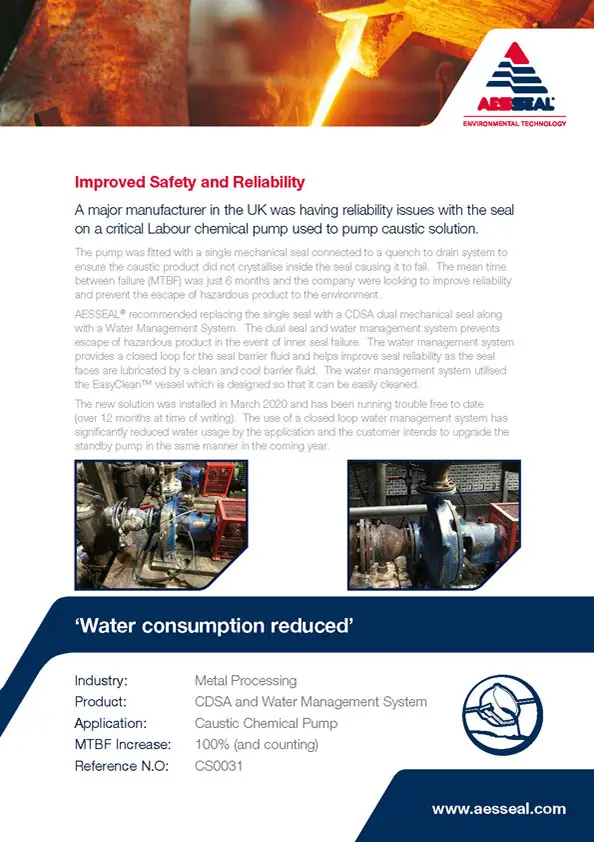

Improved Safety and Reliability

Chemical Producer Saves Over £1.7 Million in Plant Downtime

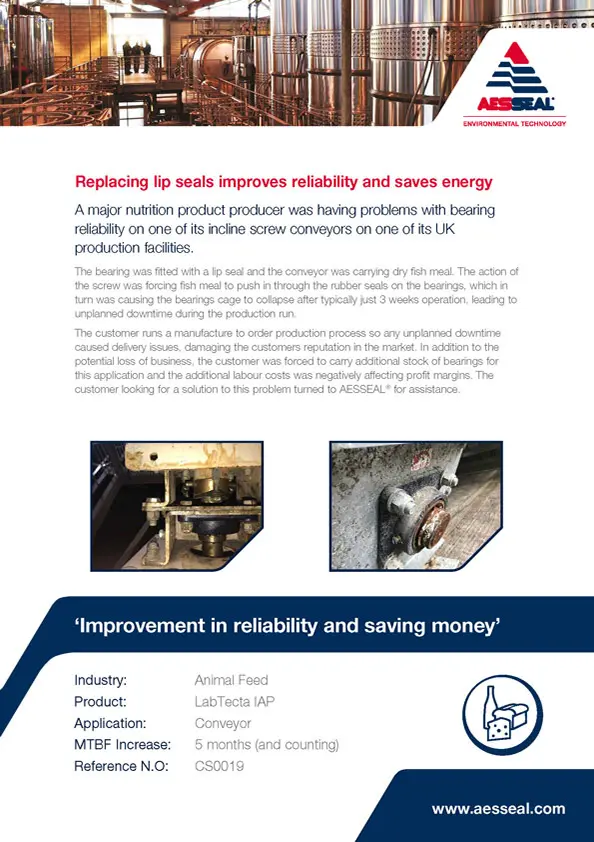

Replacing lip seals improves reliability and saves energy

Chemical company saves £9,400 and 17,000m3 of water a year

UK pulp and paper mill upgrade lip seals for bearing protection

Improving reliability, increasing efficiency

A £40,000 repair saving over 10 years

£137,830 saving & a 1100% MTBF increase

Successfully sealing cooling tower motors at Dairy Crest

DMSF upgrade saves over £460,000 a year

7 years trouble free bearing protection

Preventing steam ingress into the bearing housing

Dry Gas Seal improves reliability and leads to a major overhaul program

Replacing lip seals with LabTecta66 improves gearbox reliability

£66,000 savings after upgrading gland packing to an RDS split seal

AESSEAL upgrade solution improves MTBF and reduces costs

Upgrading from packing reduces water usage and operating costs

Upgraded mixer seal delivers £28,000 in maintenance savings

Saving water, the environment and our customers money

366% mean time between failure increase and over £5,000 per annum cost saving

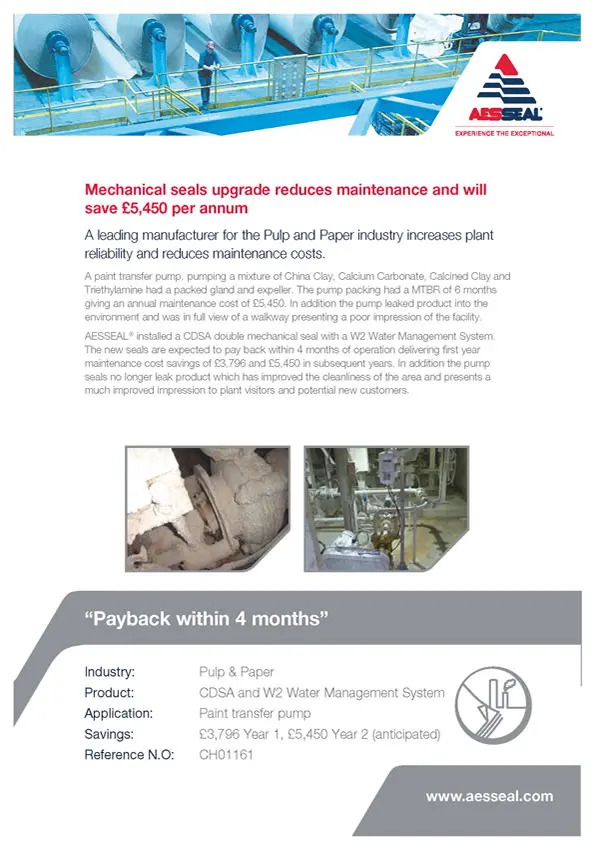

Mechanical seals upgrade reduces maintenance and will save £5,450 per annum

An upgrade to LabTecta-PB gives a 500% MTBF increase

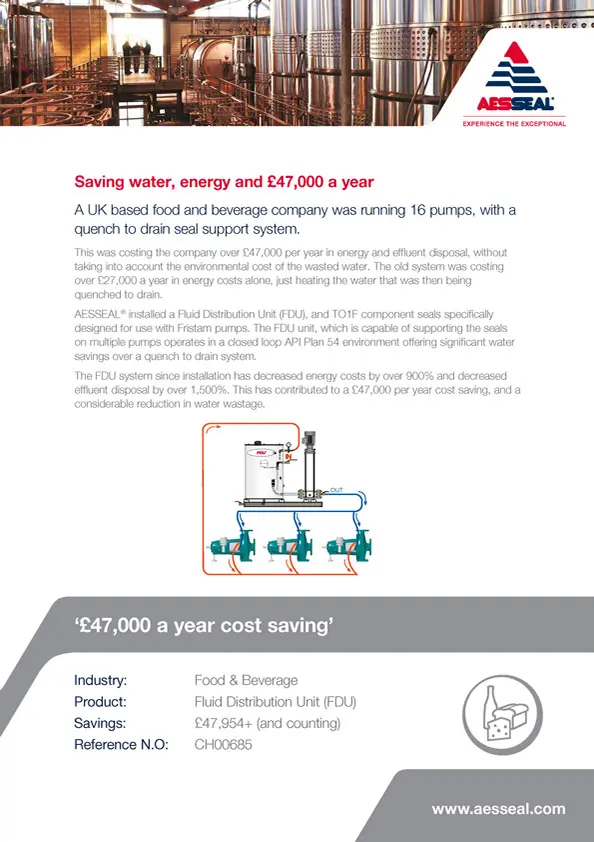

Saving water, energy and money for a food manufacturer

540% increase in MTBF rates

Unbeatable lead times on bearing protection