AESSEAL solves reliability problem for US paper company

CDSA seals brings huge savings for US company

Savings for US company with AESSEAL DMSF

Upgrade will result in major savings for US company

Huge reduction in water usage follows AESSEAL audit

Seal still giving perfect service after more than ten years

FIDC ends costly leaks at US firm

Major US food producer opts for AES-Elast

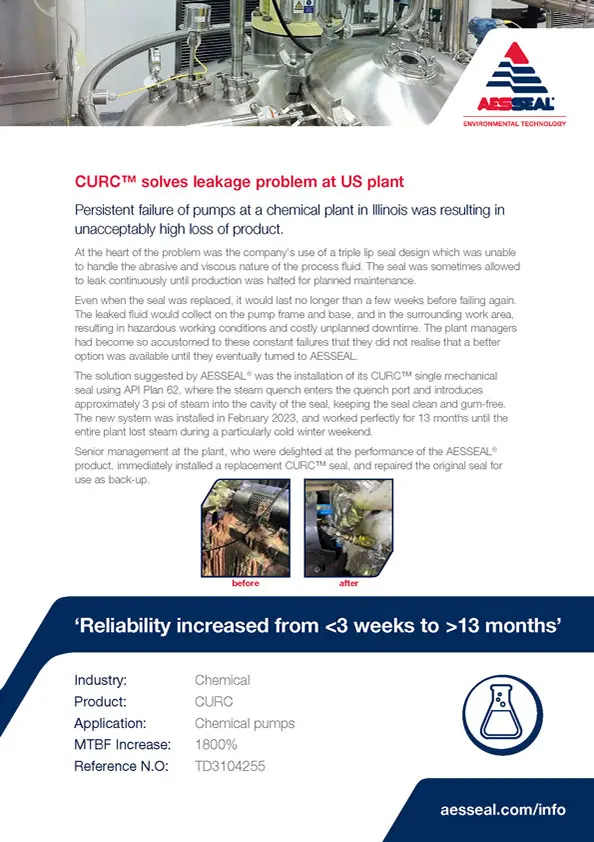

CURC solves leakage problem at US plant

Persistent failure of pumps at a chemical plant in Illinois was resulting in unacceptably high loss of product.

AESSEAL system fixes sewage problems for US township

A municipality in Pennsylvania was having issues with major inefficiencies in its sewage treatment system.

AVT sensors save thousands for US company

Excessive vibrations in a vertical pump in a slurry pit application was leading to failure every month for the North Carolina company Befesa

AESSEAL cuts water usage by 75 percent at US company

A US mining company was concerned that its large end suction pumps were using excessive amounts of water.

CURC the best option for US textile firm

Long lead times in procuring replacement parts for a large non-standard component seal were causing production delays for a US textile company.

Double seals solve reliability problem for US company

A New England pulp and paper company was reporting the persistent failure of its single seals

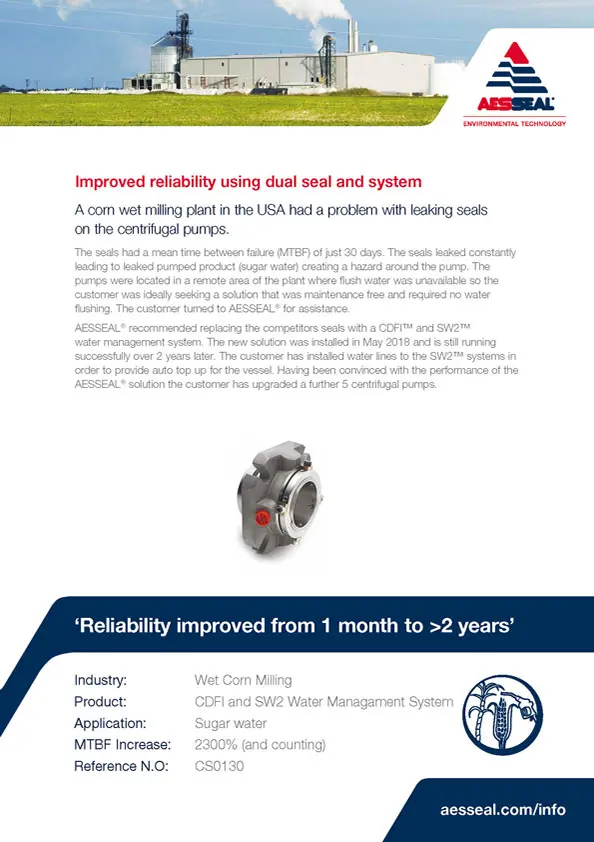

Improved reliability using dual seal and system

A corn wet milling plant in the USA had a problem with leaking seals on the centrifugal pumps.

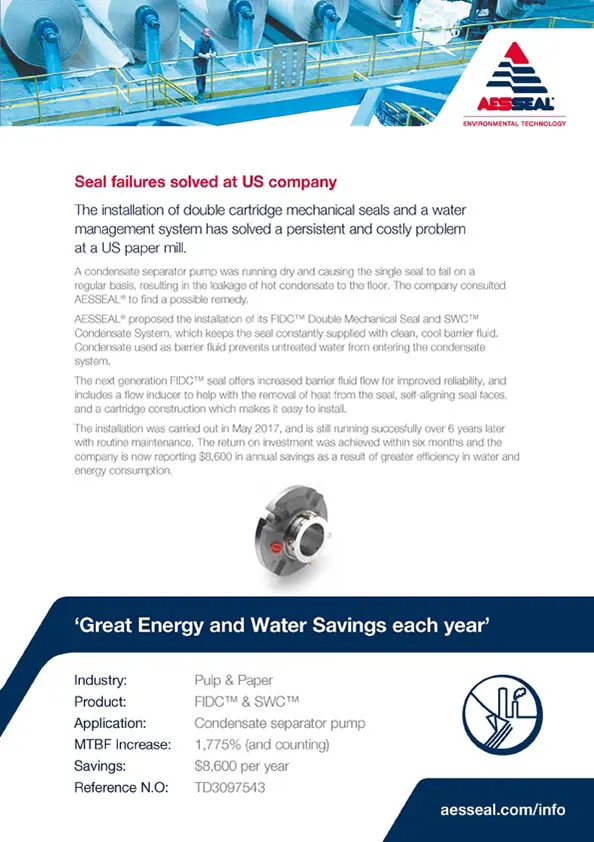

Seal failures solved at US company

LabTecta FS the answer for gearbox problem

LabTecta solves bearing problem

AESSEAL seals the deal

DMSF seal the answer for US company

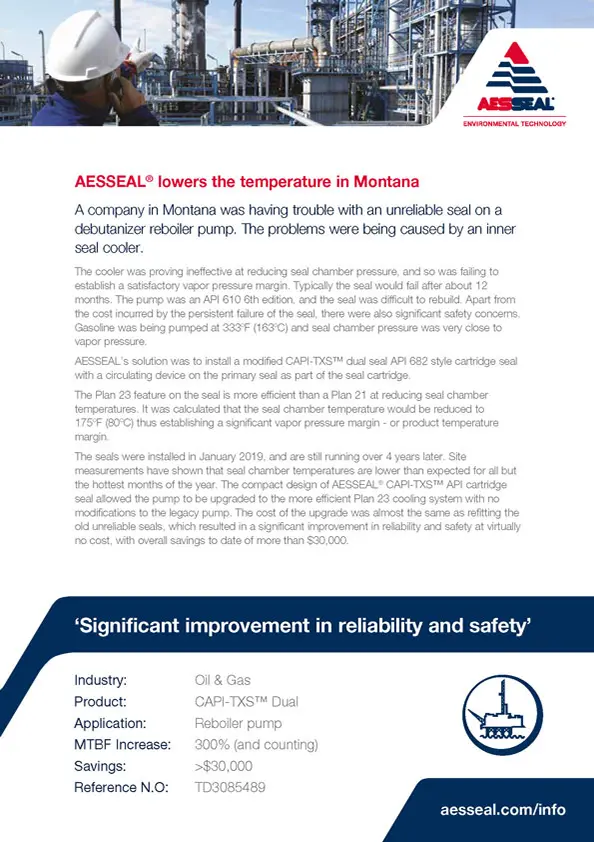

AESSEAL lowers the temperature in Montana

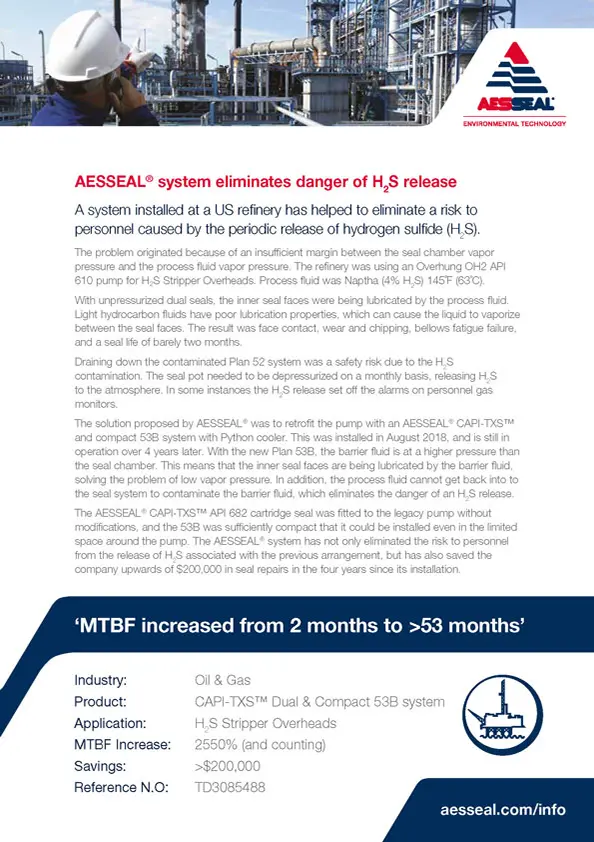

AESSEAL system eliminates danger of hydrogen sulfide release

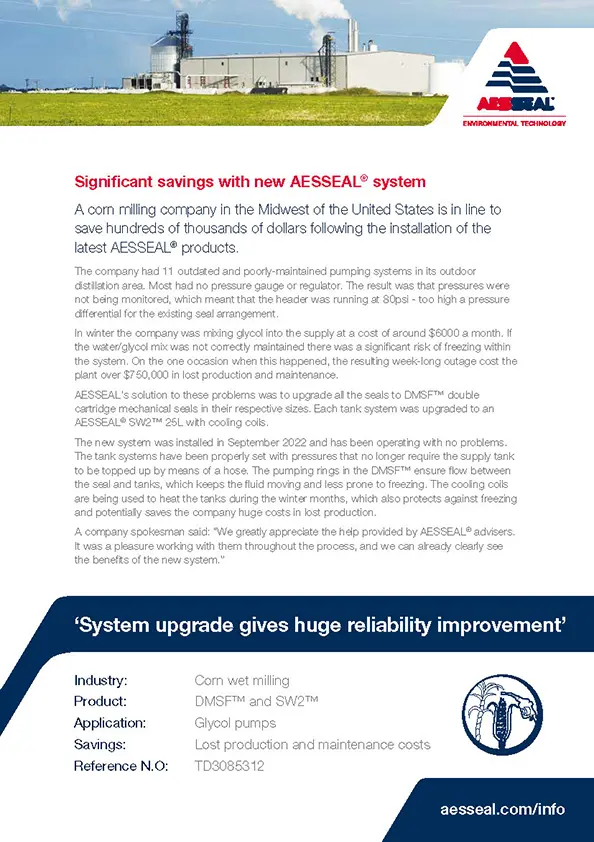

Significant savings with new AESSEAL system

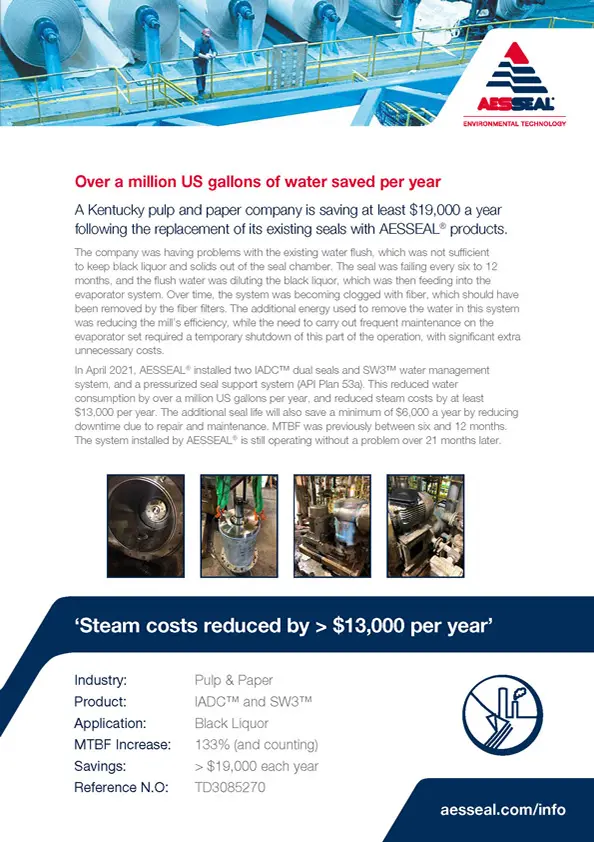

Over a million US gallons of water saved

LabTecta seals solve leakage problems

AESSEAL cures reliability issues at US wastewater facility

AESSEAL system aids clean-up at US feed mill

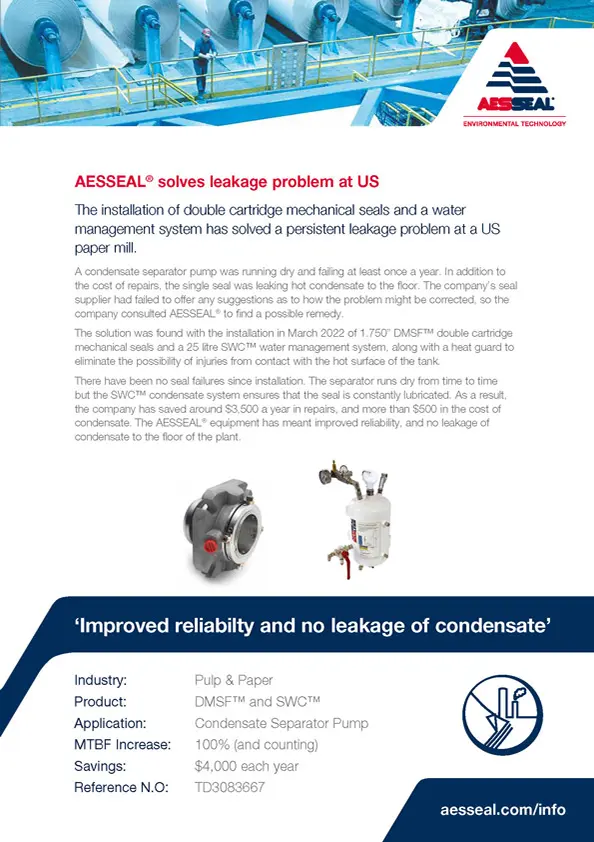

AESSEAL solves leakage problem at US paper mill

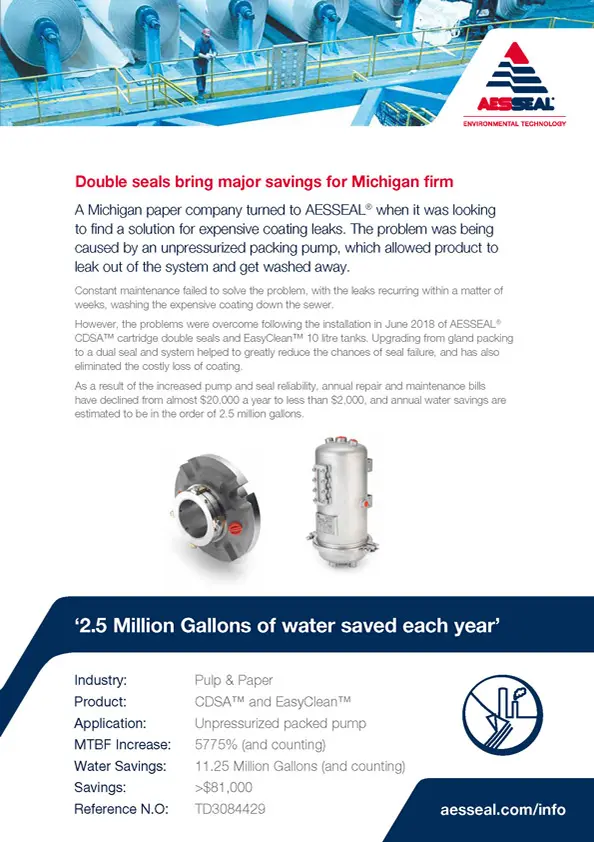

Double seals bring major savings for Michigan firm

LabTecta saving time and money at US plant

Huge cost savings for US company with Magtecta unit

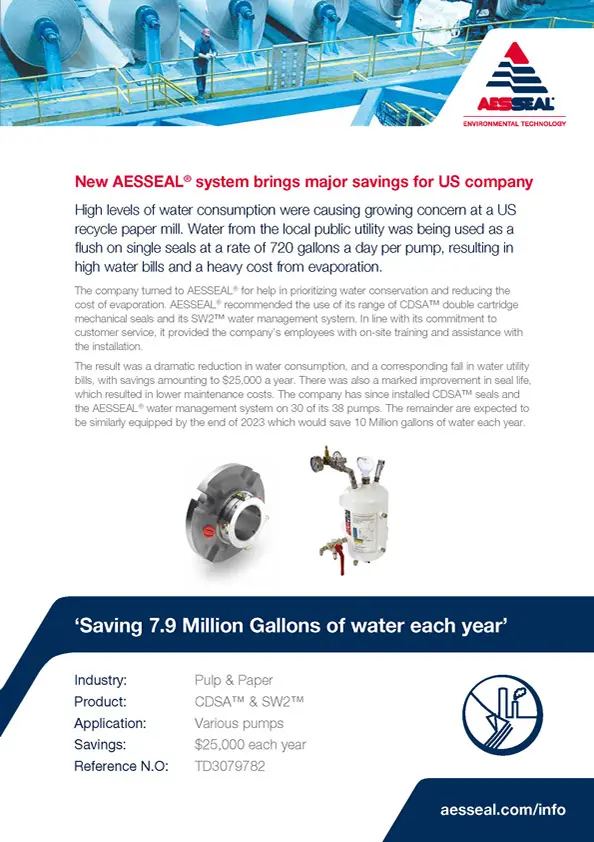

New AESSEAL system brings major savings for US company

Lower costs and greater reliability for US pharma company

AESSEAL helps significantly reduce downtime

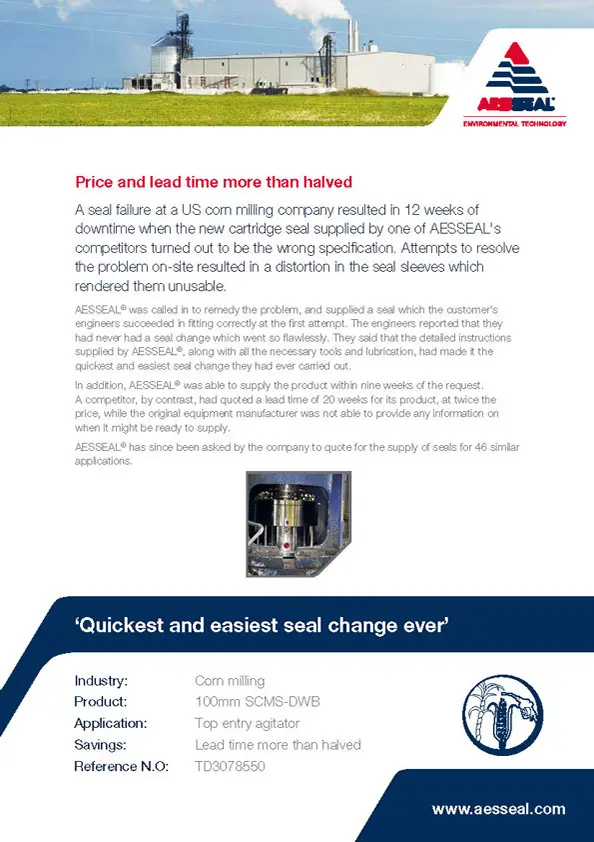

Price and lead time more than halved

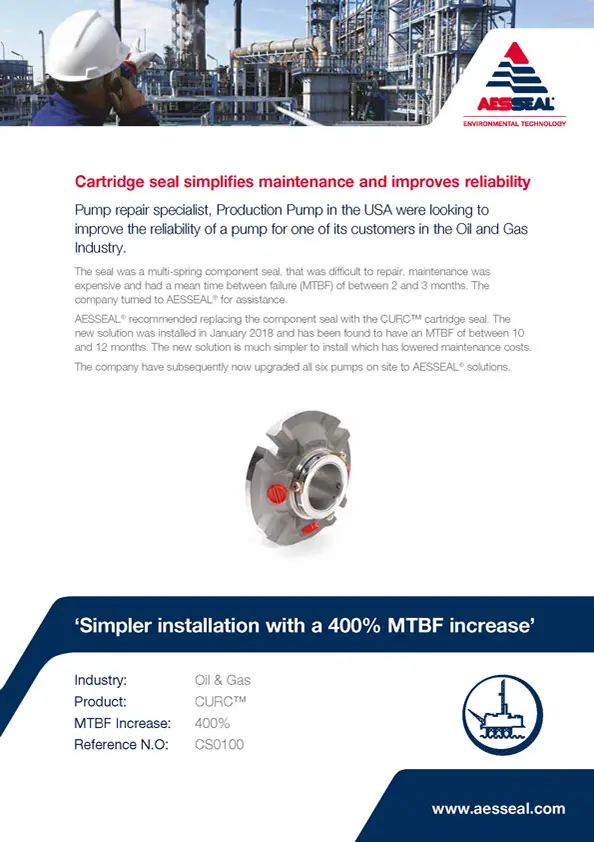

Cartridge seal simplifies maintenance and improves reliability

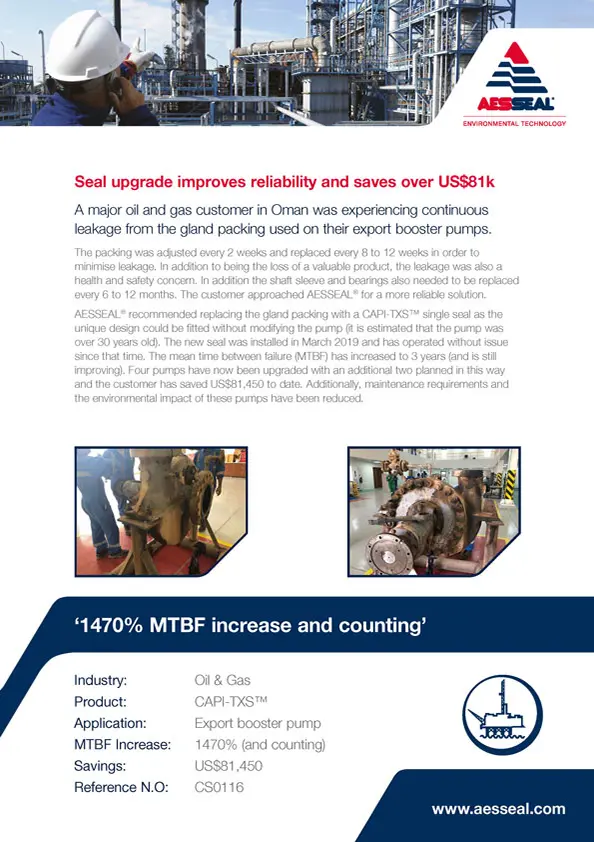

Seal upgrade improves reliability and saves over US$81k

MagTecta improves gearbox reliability

Reduce maintenance costs with reliability upgrade

Lip seal upgrade for US petrochemical plant

MagTecta improves cooling tower fan reliability

AES-Elast™ successfully replaces leading brand

Efficient seal support system reduces energy costs

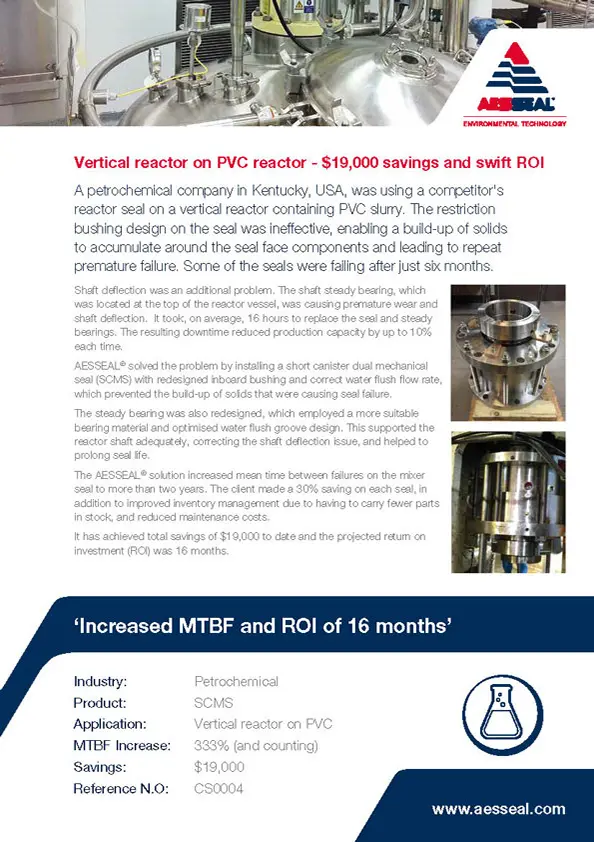

Vertical reactor on PVC reactor - $19,000 savings and swift ROI

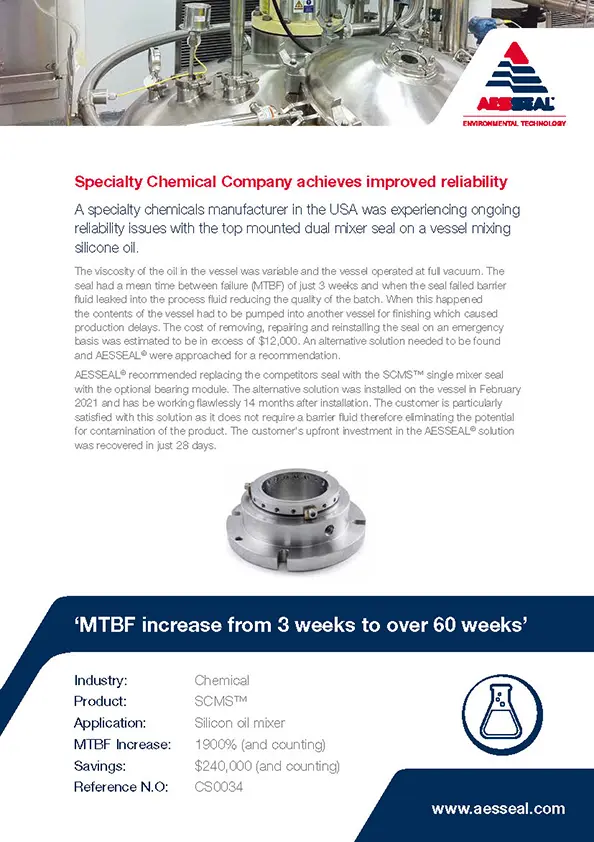

Specialty Chemical Company achieves improved reliability

LabTecta reduces quality issues and improves reliability

Success with bad actor pump leads to further opportunity

9+ Years MTBF for condensate pump

MagTecta eliminates gearbox oil leakage

LabTecta eliminates oil leakage

Change to AESSEAL helps reduce filter downtime

New seal design the difference at US firm

AESSEAL SW system solves water pressure problem

The AESSEAL DMSF helps cut water usage for US company

Reliability upgrade saves $24k per year

Solution delivers $17,000 inventory cost savings

Annual savings of over $2.6 million

Reliability upgrade improves MTBF 2900%

Gas seal gives 14 years trouble free operation

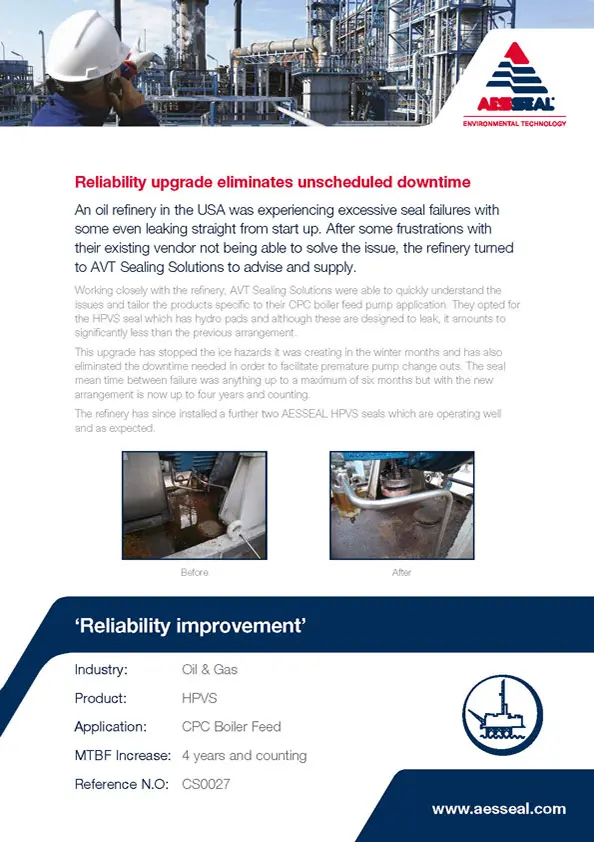

Reliability upgrade eliminates unscheduled downtime

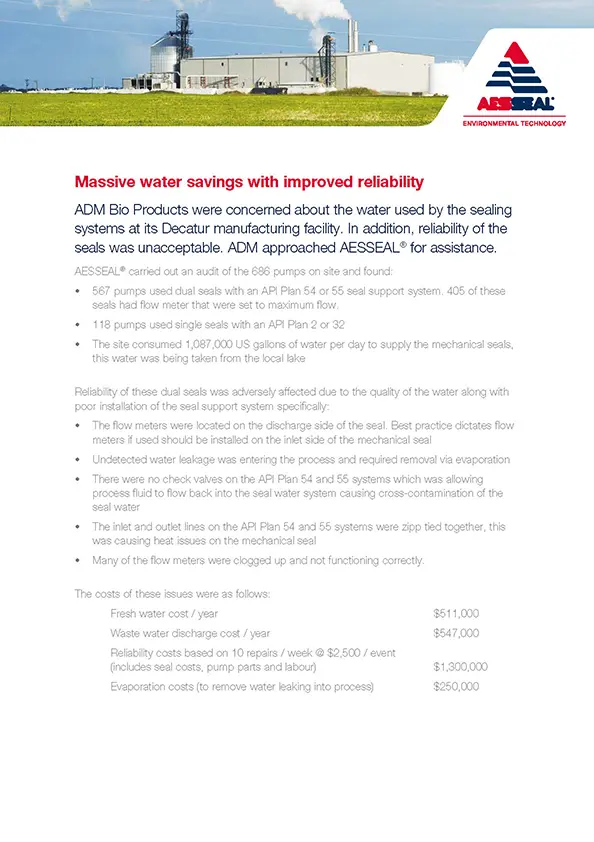

Massive water savings with improved reliability

Reduced downtime, improved safety

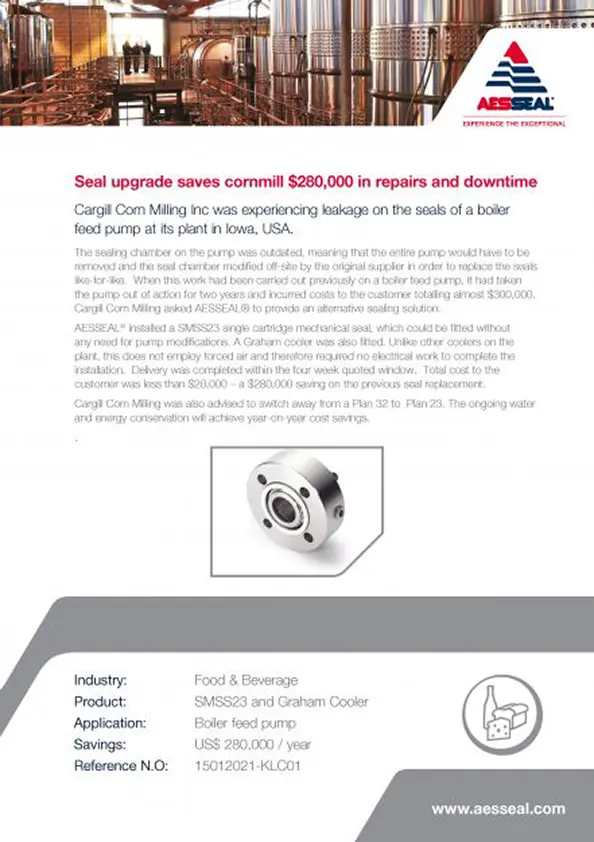

Seal upgrade saves cornmill $280,000 in repairs and downtime

Successful Support System Upgrade Improves Plant Reliability

Chemical company saves over $225,000 in first year

Reliability upgrade reduces seal repair costs

Unique solution saves $287,000 a year and improves safety

MTBF increases by 233%

Reduced downtime and health & safety benefits

Upgrade delivers annual saving of 15,000 USD

Improved safety and production efficiency while reducing water consumption

Paper producer saves more than one million Dollars per year

LabTecta upgrade gives over 12 years of trouble free operation

Eliminating a $225,000 maintenance bill

Replacing lip seals reduces cost, improves reliability and saves the environment

$40,000 a year saving with LabTecta

Upgrading unreliable seals increases MTBF from 2-3 months to 3 years

Reduced pump failure delivered over $11,000 cost saving in first year of operation

$10,500 yearly cost saving for Chemical manufacturer