Water Savings Case Studies

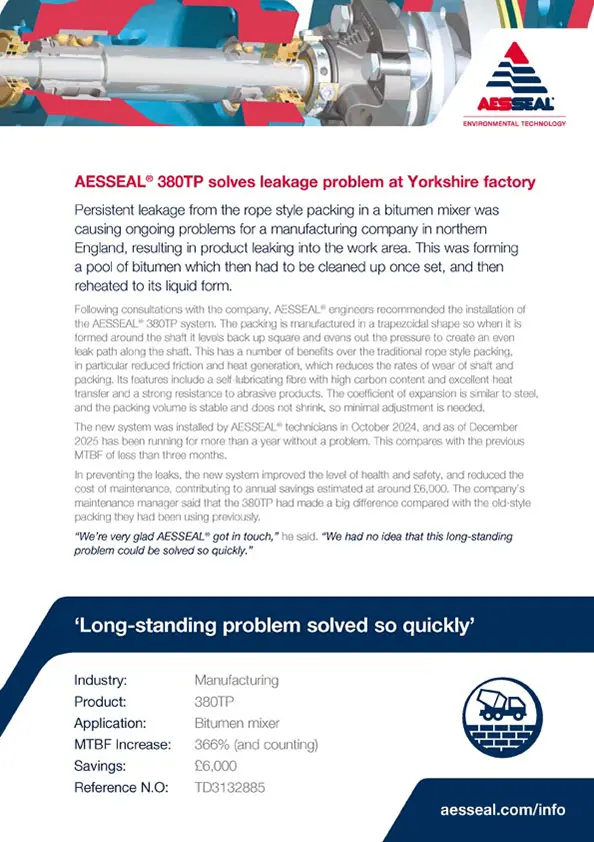

AESSEAL 380TP solves leakage problem at Yorkshire factory

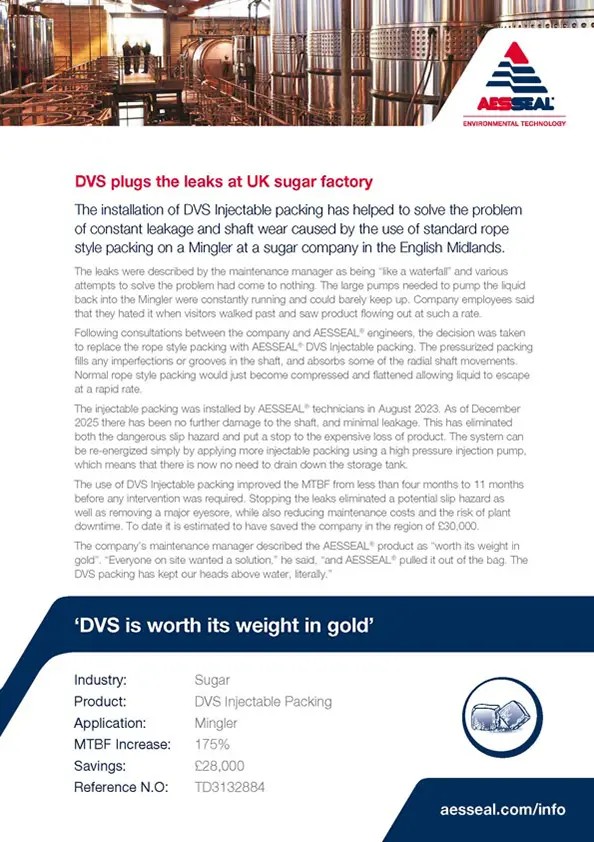

DVS plugs the leaks at UK sugar factory

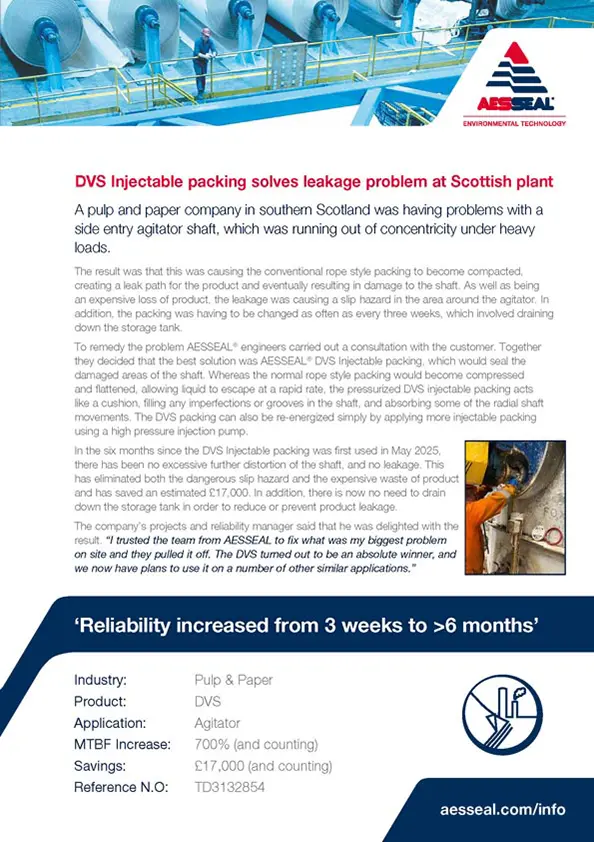

DVS Injectable packing solves leakage problem at Scottish plant

AESSEAL cleans up the brown lagoon

A sugar company in the English Midlands has saved more than £40,000 following a decision to upgrade its packing system to the AESSEAL® trapezoidal cross-section packing AESSEAL® 380TP.

AESSEAL solves reliability problem for US paper company

CURC puts an end to leakage problem

CDSA seals brings huge savings for US company

DVS saves thousands for UK firm

Major savings for SA company

Company reports huge savings with use of AESSEAL system

Huge reduction in water usage follows AESSEAL audit

CDPH brings big savings for Botswana company

DMSF makes its mark in Japanese paper industry

DMSF solves reliability issues for Swedish company

CDSA provides major savings for German company

Seal still giving perfect service after more than ten years

Reliability the key with DISP seals and FLOWTRUE

SW2 brings huge water savings for French brewery

Major water savings at South African paper company

FIDC cleans up at salt plant

Staying cool in Cardiff

AESSEAL solves reliability problems for paper company

AESSEAL upgrade solves bearing failure problem

CDM the key to greater reliability

EasyClean cuts water usage at French milk plant

Installation of the EasyClean™ water management system helped French milk production company to improve its hygiene standards and reduce water usage.

System Sentry proves its worth in INEOS field trial

Engineers at the petrochemicals manufacturer INEOS have given the seal of approval to the AESSEAL® monitoring device System Sentry® following a field trial at the company’s plant in Hull in the east of England.

CDM reliability the answer for seal failures

A corrugated packaging plant in northern France was experiencing persistent seal failures, on average every two months.

EasyClean the answer to excessive water use

Unacceptably high water consumption was a concern for a confectionery company in northern France.

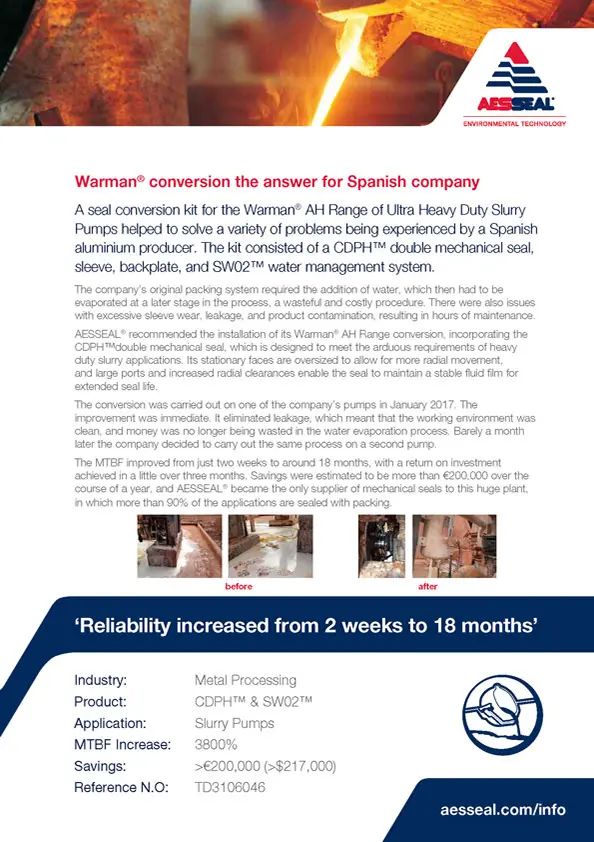

Warman conversion the answer for Spanish company

A seal conversion kit for the Warman® AH Range of Ultra Heavy Duty Slurry Pumps helped to solve a variety of problems being experienced by a Spanish aluminium producer.

Enhanced production reliability

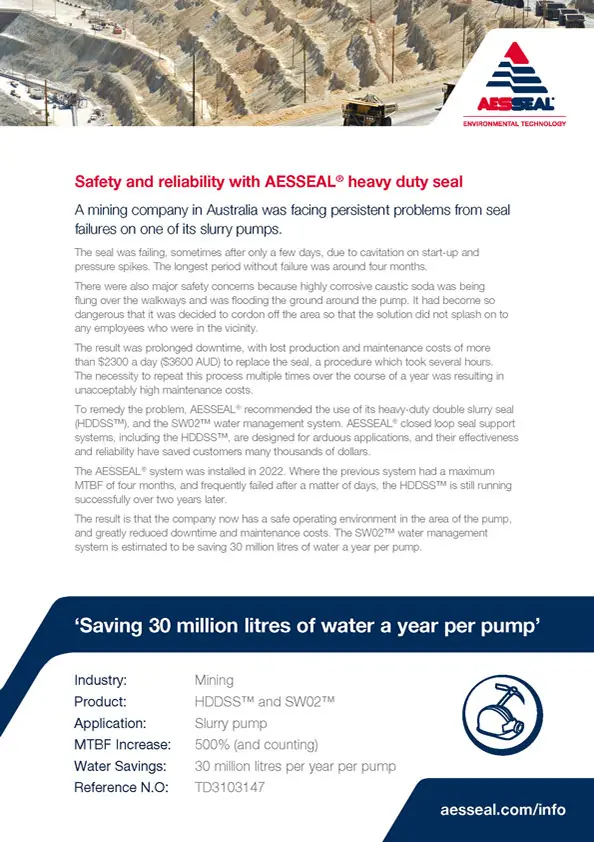

Safety and reliability with AESSEAL heavy duty seal

A mining company in Australia was facing persistent problems from seal failures on one of its slurry pumps.

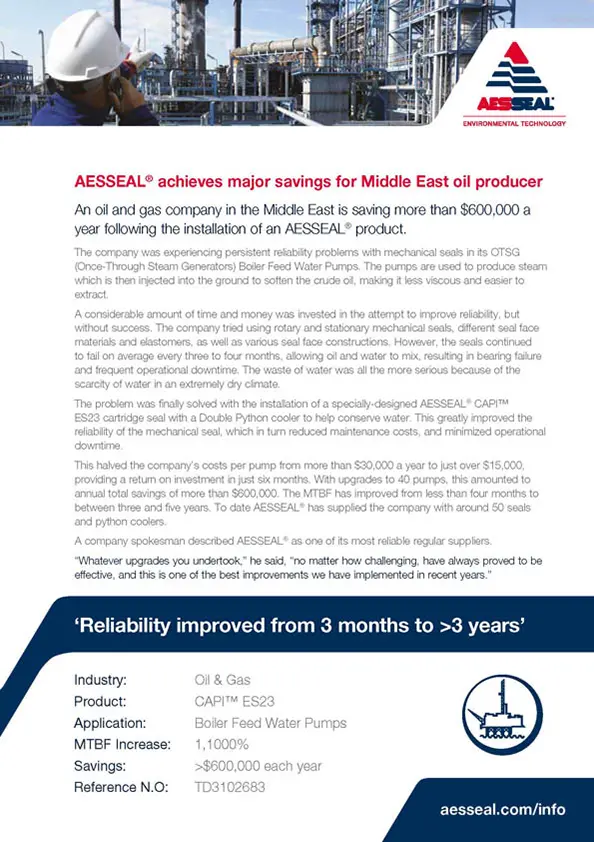

AESSEAL achieves major savings for Middle East oil producer

An oil and gas company in the Middle East is saving more than $600,000 a year following the installation of an AESSEAL product.

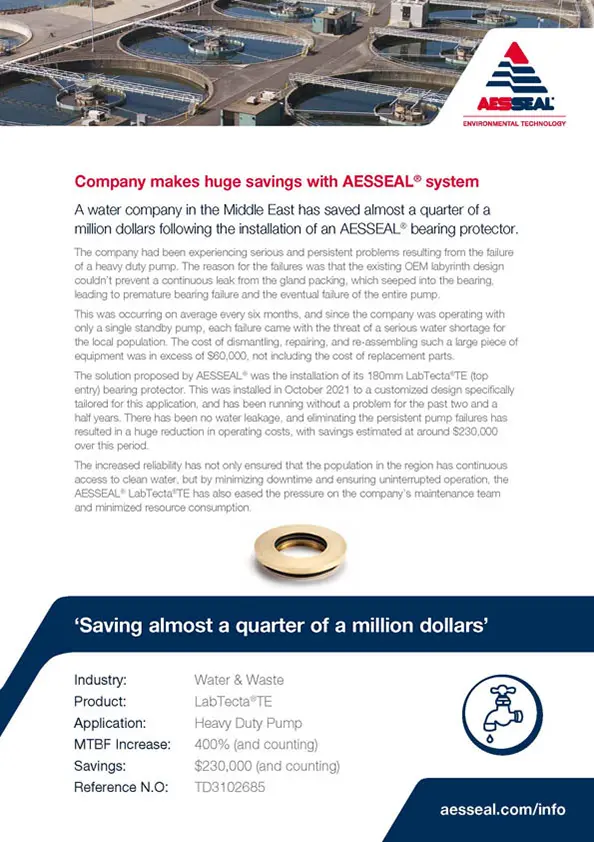

Company makes huge savings with AESSEAL system

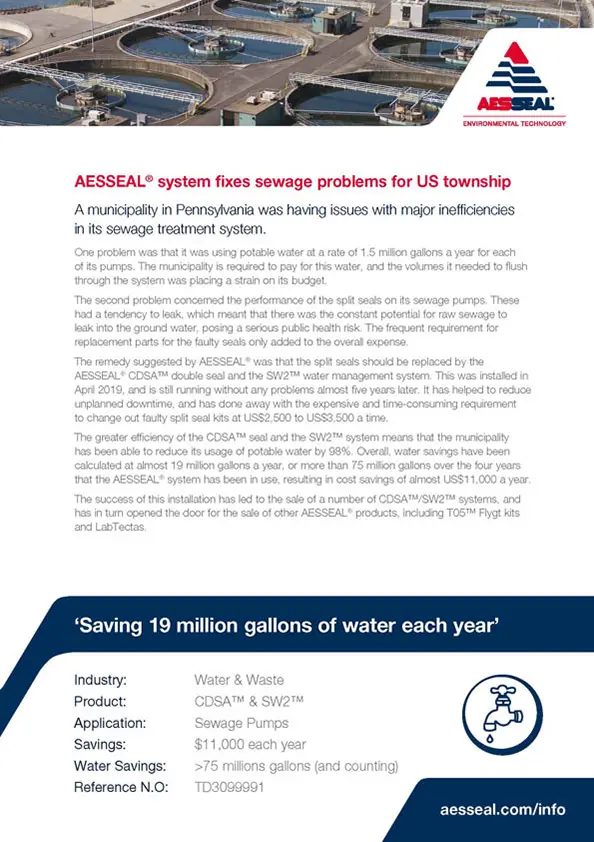

AESSEAL system fixes sewage problems for US township

A municipality in Pennsylvania was having issues with major inefficiencies in its sewage treatment system.

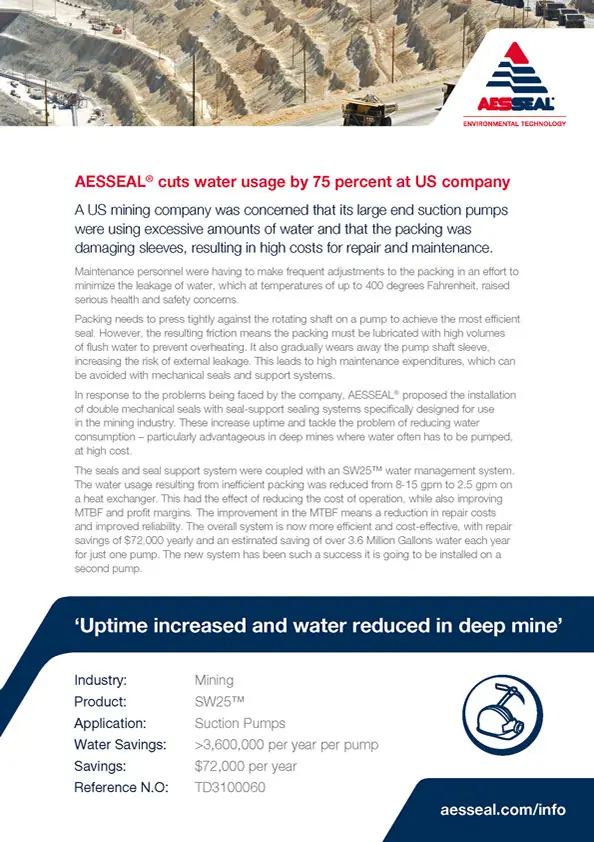

AESSEAL cuts water usage by 75 percent at US company

A US mining company was concerned that its large end suction pumps were using excessive amounts of water.

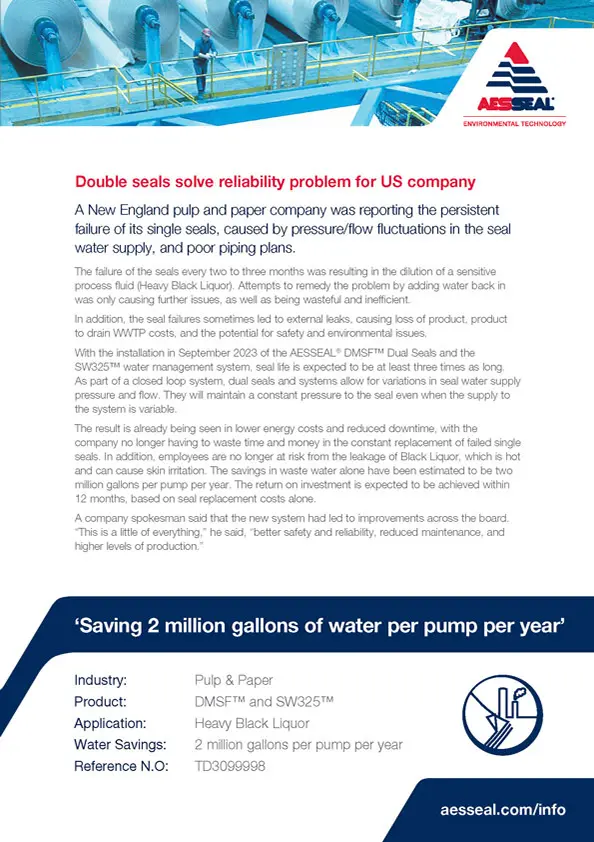

Double seals solve reliability problem for US company

A New England pulp and paper company was reporting the persistent failure of its single seals

Seal failures solved at US company

Sweet solution for sugar producer

AESSEAL product stops hot oil pump leakage

Fantastic seal life for notoriously difficult application

Over a million US gallons of water saved

LabTecta seals solve leakage problems

AESSEAL cures reliability issues at US wastewater facility

AESSEAL system aids clean-up at US feed mill

Double seals bring major savings for Michigan firm

New AESSEAL system brings major savings for US company

Lower costs and greater reliability for US pharma company

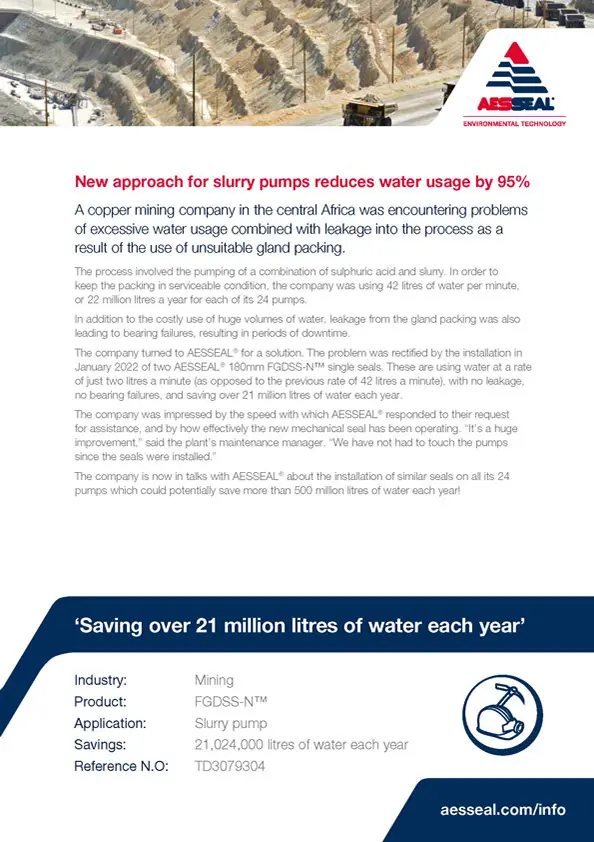

New approach for slurry pumps reduces water usage by 95%

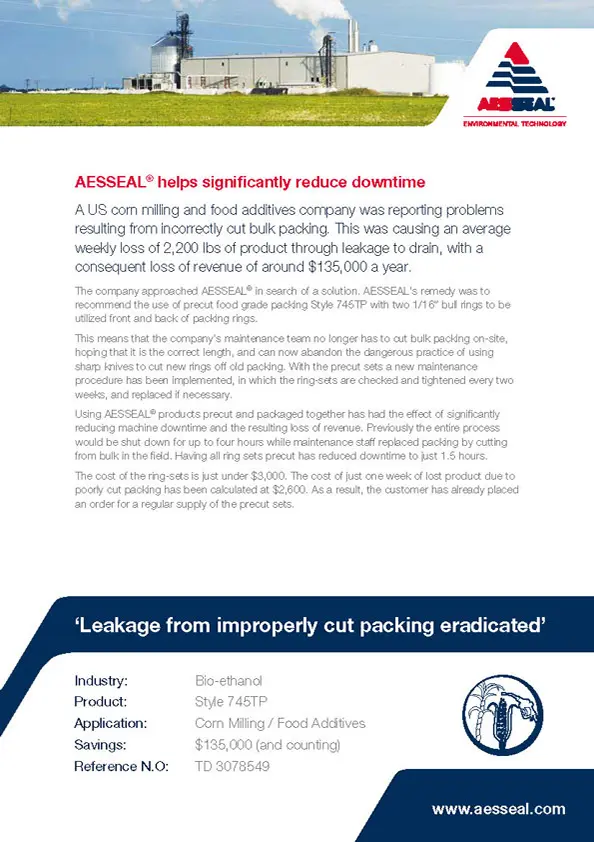

AESSEAL helps significantly reduce downtime

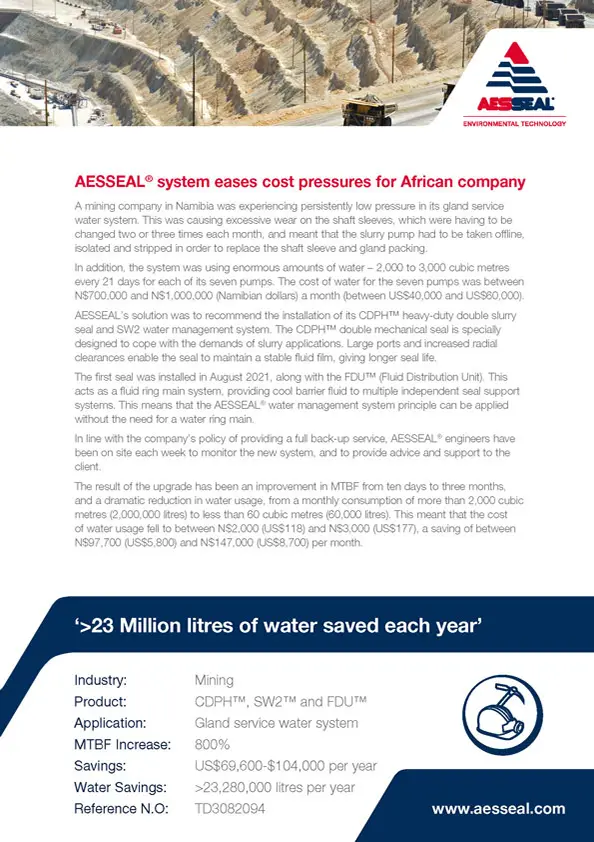

AESSEAL system eases cost pressures for African company

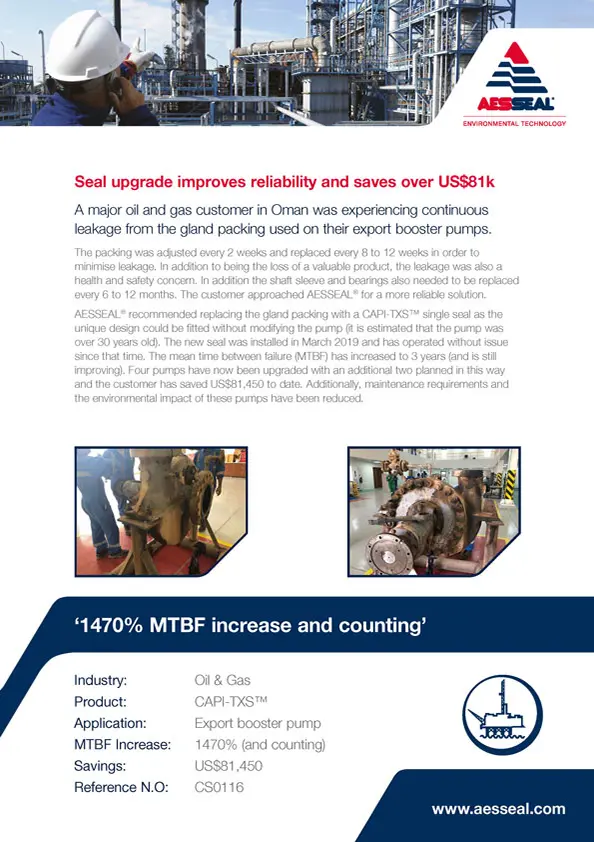

Seal upgrade improves reliability and saves over US$81k

Reliability upgrade reduces water consumption

Improving reliability and reducing product loss for sugar Refinery

DMSF seals halt water leakage

MagTecta improves gearbox reliability

LabTecta the answer for SA chemical company

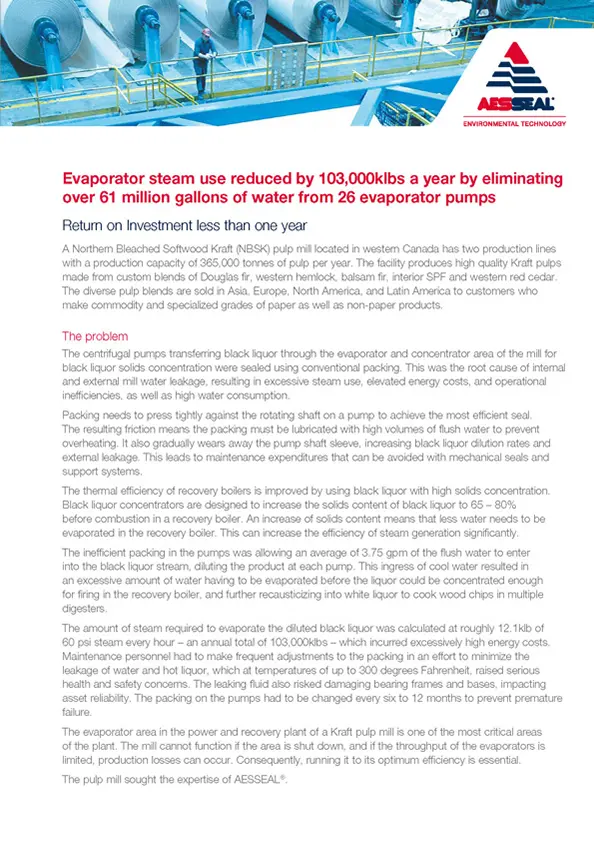

Eliminating over 61 million gallons of water from 26 evaporator pumps

Massive water savings with new seal

Success with bad actor pump leads to further opportunity

AESSEAL SW system solves water pressure problem

The AESSEAL DMSF helps cut water usage for US company

AESSEAL product aids major cuts to water usage

Trapezoidal Packing Improves Reliability

Water and cost savings with reliability upgrade

Annual savings of over $2.6 million

ZAR84,000 Saving with reliability upgrade from packing

Reliability upgrade improves reliability 700%

Massive water savings with improved reliability

Specialist paper producer saves almost 6.4 million litres of water per year

Mean time between failure doubles

Over 20 million litres of water saved in 5 years for just 2 pumps

Seal upgrade saves cornmill $280,000 in repairs and downtime

Improved Safety and Reliability

Dual Seal Upgrade saves over 17 million litres of water

Counterproductive flush water in an evaporator pump leads to big savings

Huge water savings for uranium mine

Upgrade from packing to mechanical seals for reliability

Savings all round for South African beer producer

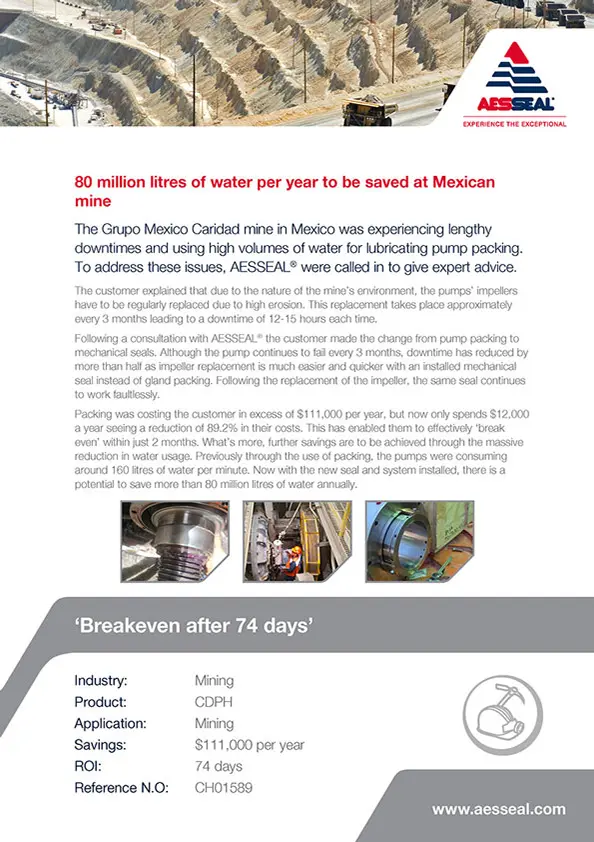

80 million litres of water per year to be saved at Mexican mine

Improved reliability and reduced water consumption

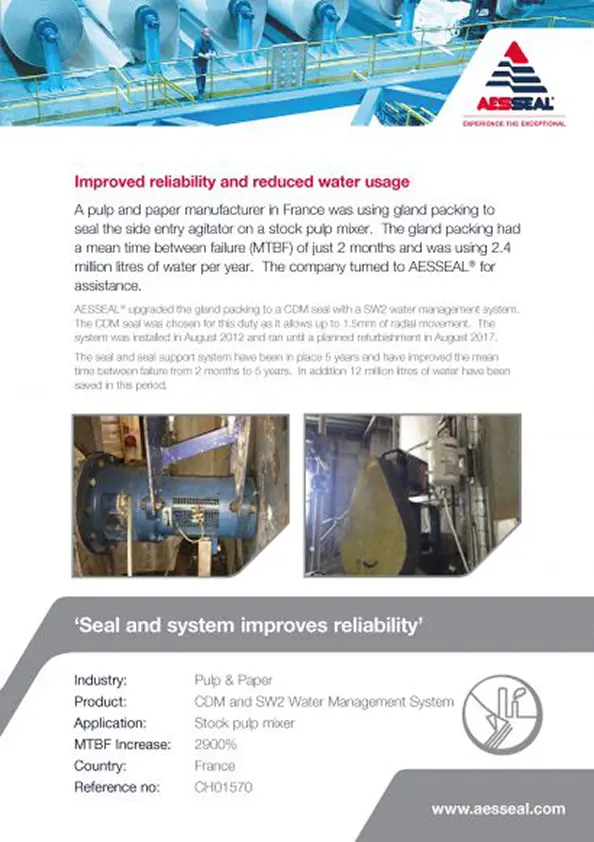

Improved reliability and reduced water usage

Huge Water Savings for Distillery

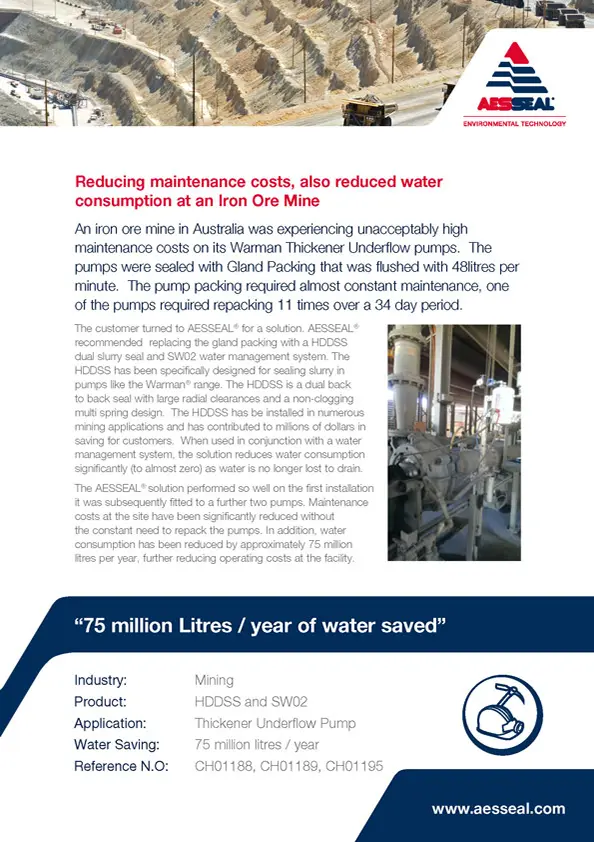

Reduced maintenance and water consumption at Iron Ore Mine

Improved safety and production efficiency while reducing water consumption

Chemical company saves £9,400 and 17,000m3 of water a year

Water Savings for South African Corn Miller

Energy Savings for Italian Corn Miller

Saving over 1 billion gallons of water

High Pressure Vertical Mixer Processing Starch

Zinc Smelting Plant Saves Thousands

Paper producer saves more than one million Dollars per year

Eliminating unplanned maintenance with API Plan 32

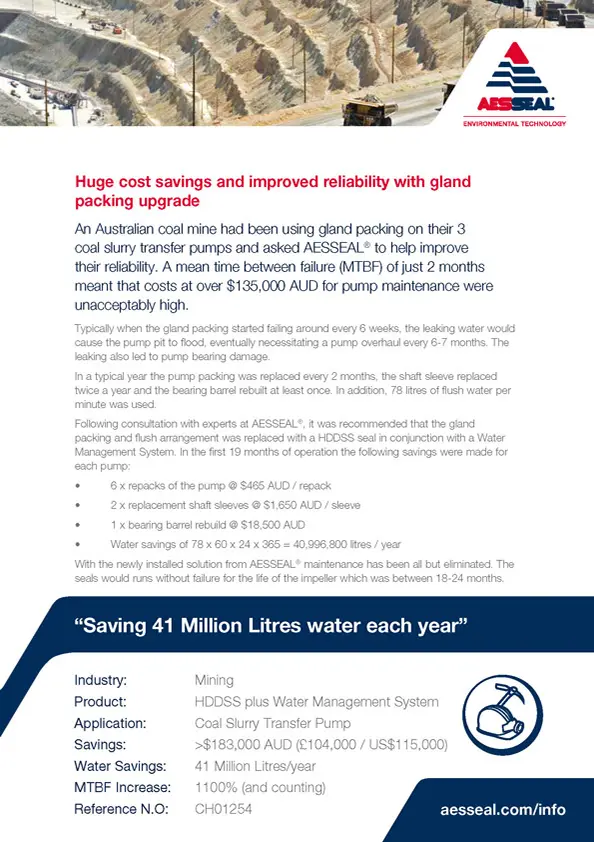

Huge cost savings and improved reliability with gland packing upgrade

DMSC saves Nestlé Purina £182k in just 10 months

Reducing Energy Usage and Improving Reliability

Mondi Meets Sustainability Targets

LabTecta upgrade gives over 12 years of trouble free operation

Replacing gland packing reduces cost, and improves reliability

£66,000 savings after upgrading gland packing to an RDS split seal

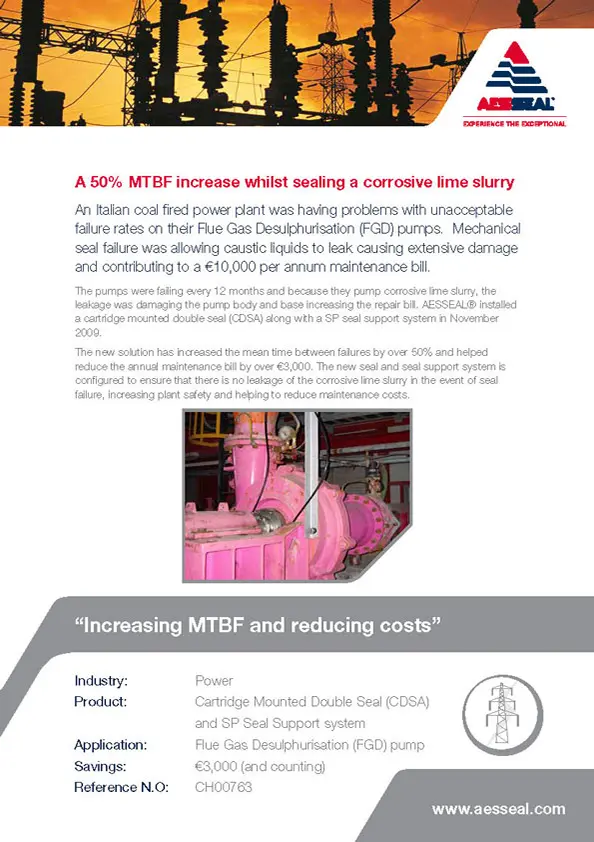

A 50% MTBF increase whilst sealing a corrosive lime slurry

Upgrading from packing reduces water usage and operating costs

Helping to keep the water flowing for South Australia

$40,000 a year saving with LabTecta

Upgrade eliminates environmental impact and delivers a 833% MTBF improvement

Saving water, the environment and our customers money

A $30,000 yearly saving for Australian copper mine

Saving water, energy and money for a food manufacturer