Compatability Case Studies

LabTecta ends contamination problem at Australian mining company

Improved reliability with AESSEAL packing system

AESSEAL cleans up the brown lagoon

A sugar company in the English Midlands has saved more than £40,000 following a decision to upgrade its packing system to the AESSEAL® trapezoidal cross-section packing AESSEAL® 380TP.

CURC solves leakage problem for Saudi company

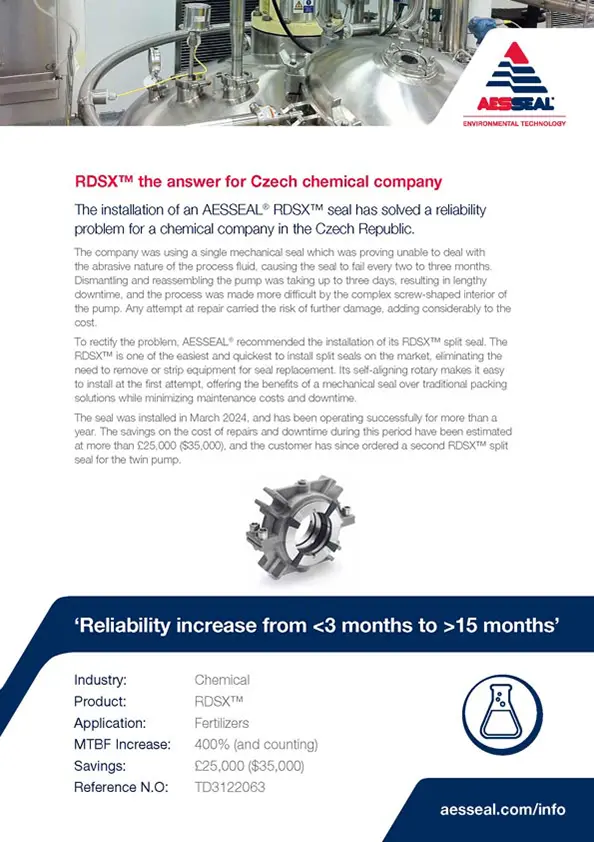

RDSX the answer for Czech chemical company

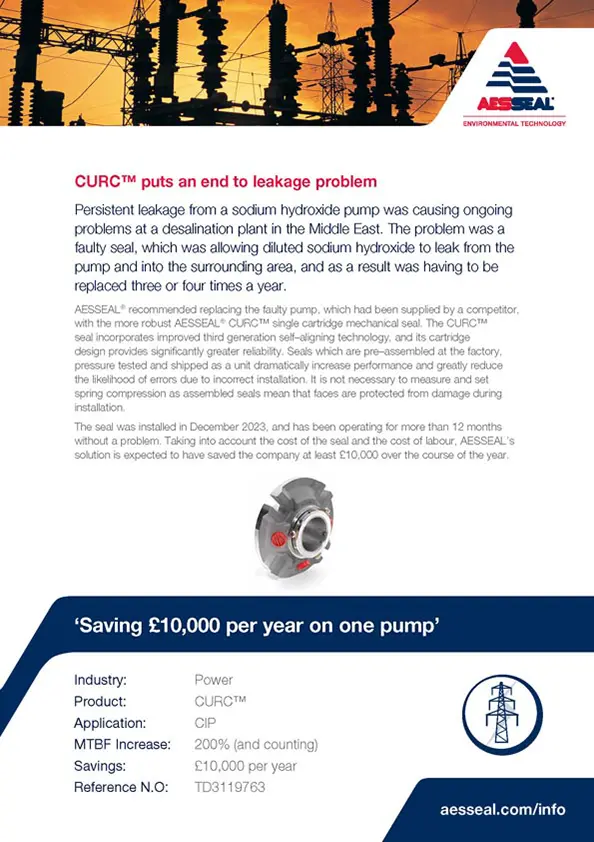

CURC puts an end to leakage problem

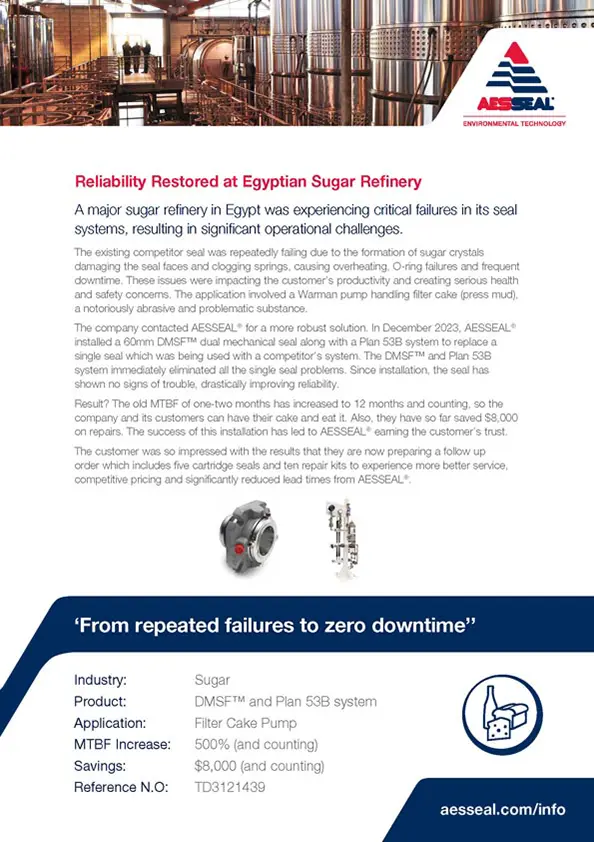

Reliability restored at Egyptian sugar refinery

Dual seal cuts costs for UAE company

DMSF seal saves thousands for Australian company

Superior AESSEAL product and service seals the deal

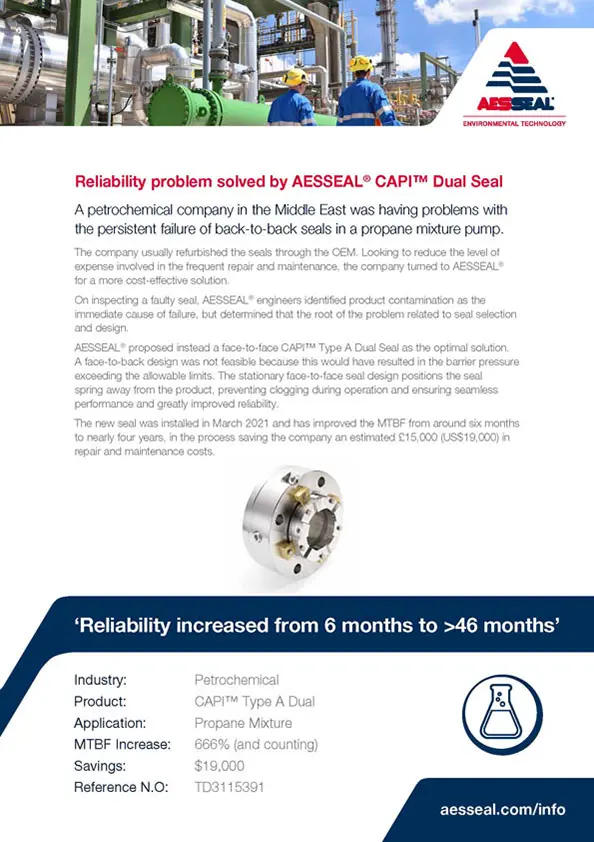

Reliability problem solved by AESSEAL CAPI Dual Seal

CDPH brings big savings for Botswana company

Major savings for SA company

Reliability guaranteed with installation of LabTecta AX

Prompt delivery saves three-month delay

CAPI-TXS the answer for legacy quench oil pumps

SW2 brings huge water savings for French brewery

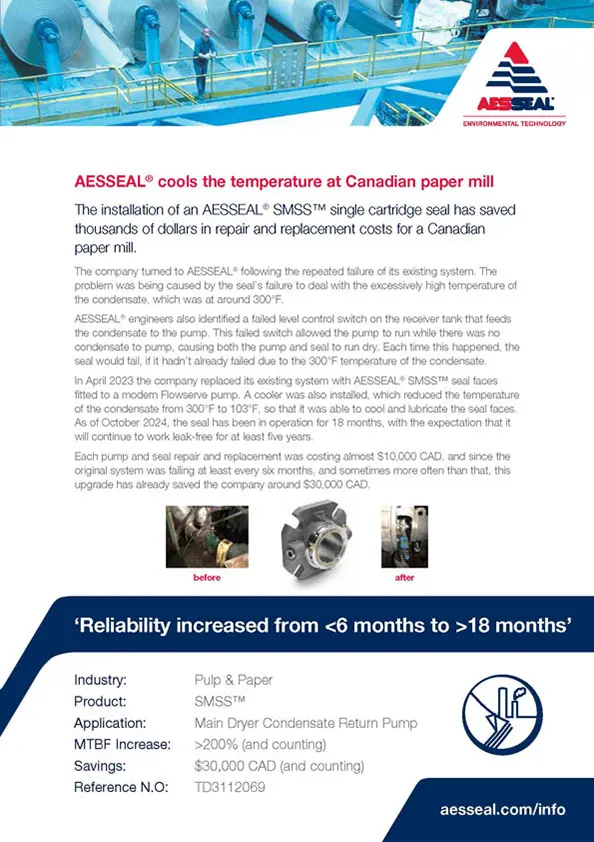

AESSEAL cools the temperature at Canadian paper mill

STS seal and LabTecta ST ends steam leak hazard

DMSF seal the answer at South African plant

LabTecta saves €360,000 for Spanish company each year

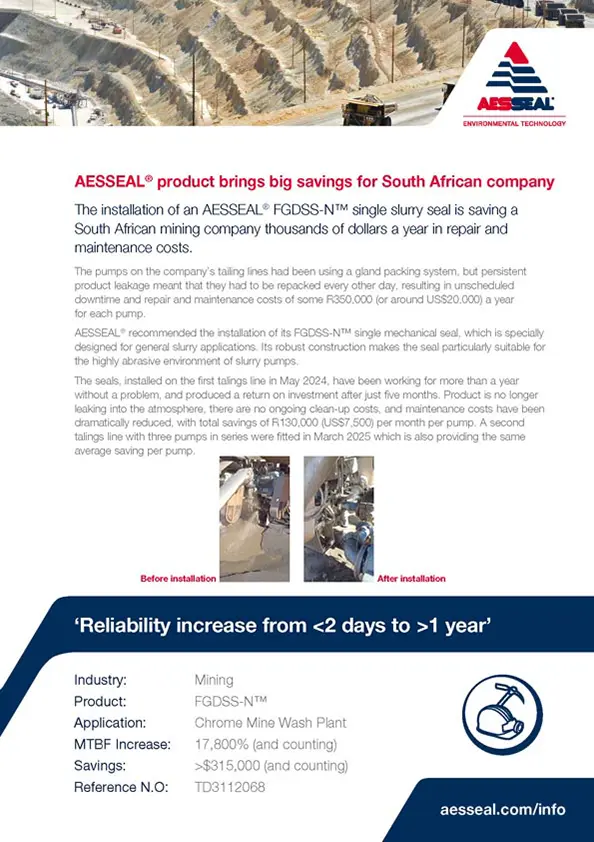

AESSEAL product brings big savings for South African company

CFFC dual seal solves reliability issues

Staying cool in Cardiff

FIDC ends costly leaks at US firm

AESSEAL product solves reliability problem

Major US food producer opts for AES-Elast

CKSA seal ensures reliability for UAE company

CDPH & EasyClean boosts MTBF from four months to seven years

CDPN seal the right fit for faulty slurry pump

AESSEAL packing guarantees highest food quality

AESSEAL LabTecta the answer for Turkish company

AESSEAL upgrade solves bearing failure problem

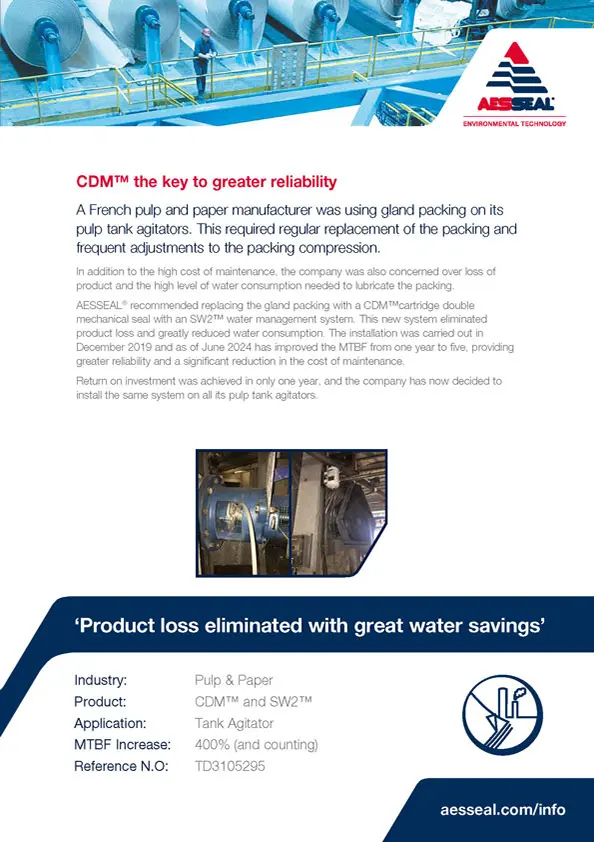

CDM the key to greater reliability

Cairo company turns to LabTecta OP

The installation of the LabTecta OP bearing protection system at the Egyptian food production company NCMP (National Company for Maize Products) resulted in an immediate and dramatic improvement in reliability.

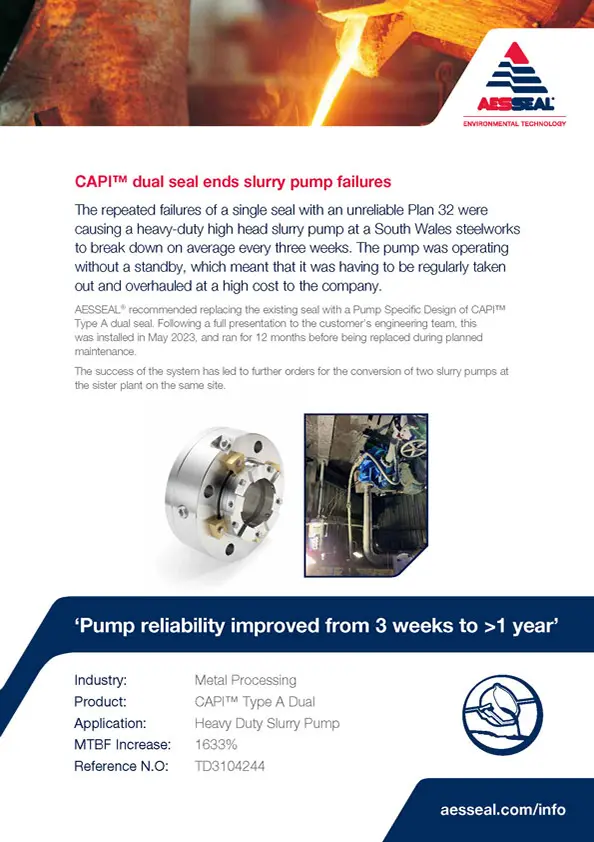

CAPI dual seal ends slurry pump failures

The repeated failures of a single seal with an unreliable Plan 32 were causing a heavy-duty high head slurry pump at a South Wales steelworks to break down on average every three weeks.

Change to packing saves Swiss company $millions

A chocolate producer in Switzerland has saved around ₣2.3 million ($2.6 million) over the past year following its decision to change to an AESSEAL pump packing system.

AES-Elast the answer to seal selection problem

Employees at William Grant’s Scottish whisky distillery in Girvan, Ayshire, were having difficulty selecting the correct mechanical seals for specific applications.

AESSEAL is always available to help when needed

A South African mining company was continually being forced to halt operations at one of its plants when a competitor’s seal persistently failed at start-up.

Safety and reliability with AESSEAL heavy duty seal

A mining company in Australia was facing persistent problems from seal failures on one of its slurry pumps.

Company makes huge savings with AESSEAL system

Style 343 a lasting solution for Gulf power company

Problems with gland packing prompted a power and desalination plant in the Middle East to turn to AESSEAL.

Autoclave specialist chooses AESSEAL for reliability and customer service

A Turkish phosphate fertiliser was established following a requirement for Turkey to produce most its own phosphate fertiliser.

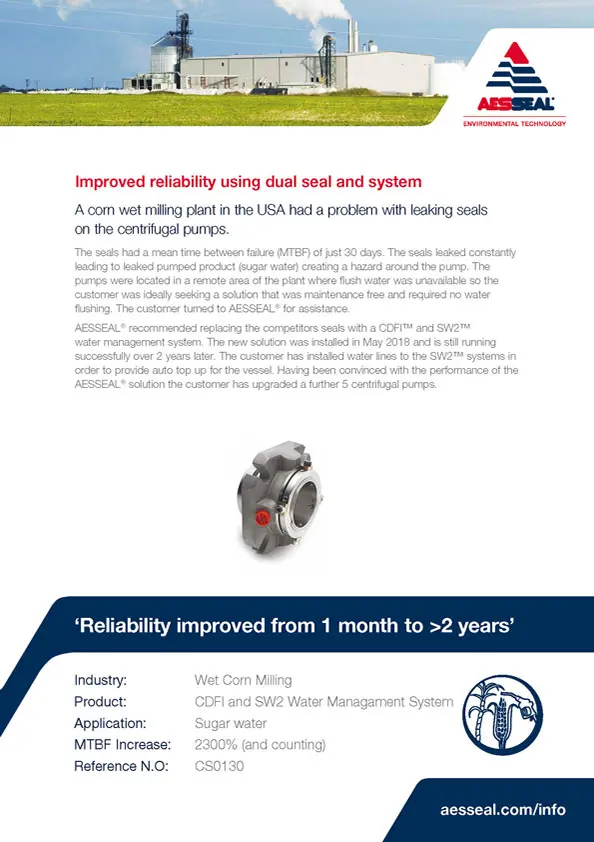

Improved reliability using dual seal and system

A corn wet milling plant in the USA had a problem with leaking seals on the centrifugal pumps.

Improved reliability for Flygt pump

A water utility company in the United Arab Emirates were dissatisfied with the performance of the mechanical seals in its Flygt pump.

Exceptional service saves thousands in lost revenue

AESSEAL were contacted by a power plant in the UK who were experiencing a major issue with their supply of mechanical seals.

Improved Reliability for difficult application

A power plant in the UK were having frequent failures of the mechanical seal on a water circulating pump.

Major savings follow installation of AESSEAL product

A petrochemical company based in the Middle East was having problems with persistent and costly seal failures.

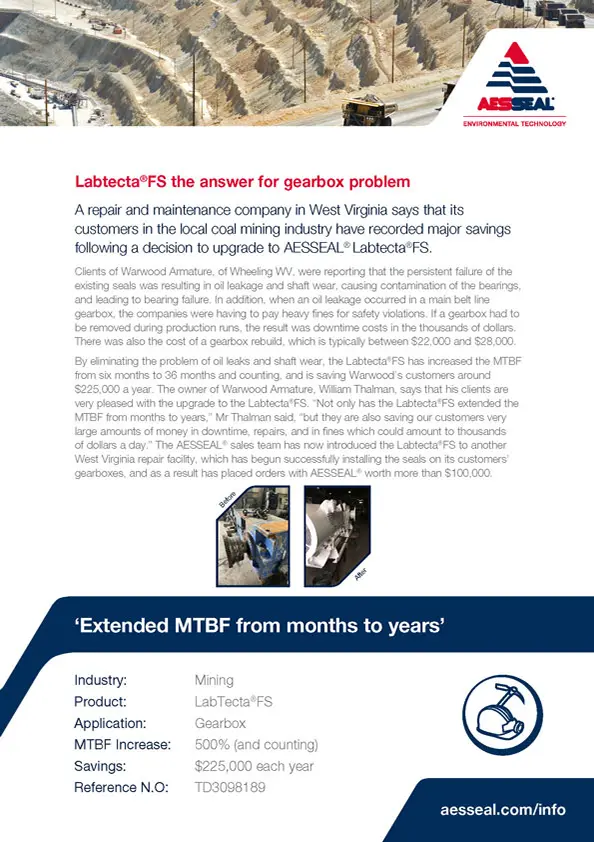

LabTecta FS the answer for gearbox problem

Upgrade solves contamination problem

STS steam seal updates UK Ethylene plant

AESSEAL product stops hot oil pump leakage

UK oil refinery close to shutting down following labyrinth seal failure

Solar energy component manufacturer increases MTBF

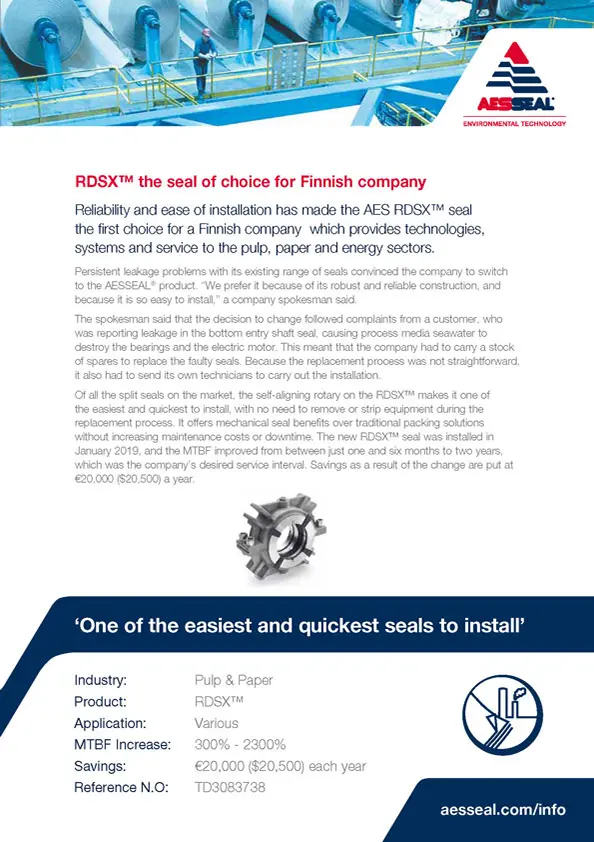

RDSX the seal of choice for Finnish company

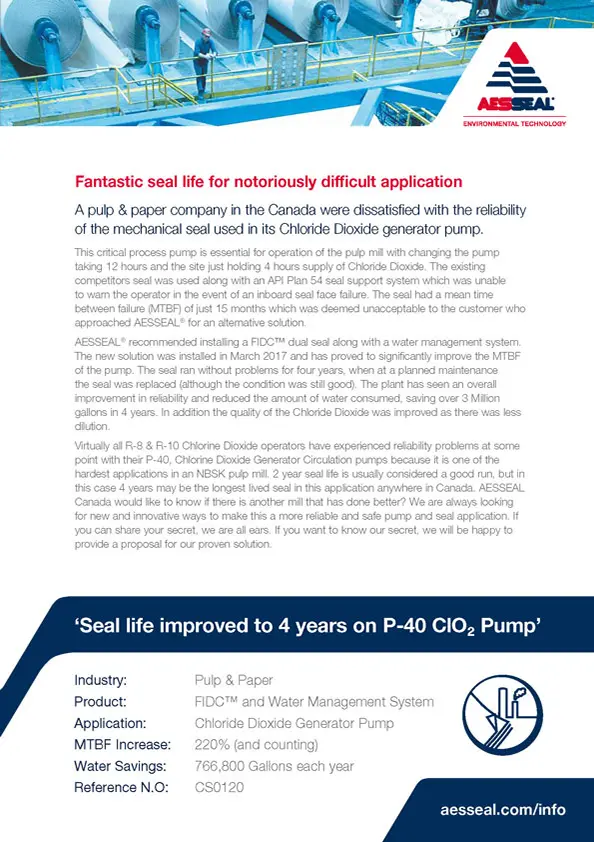

Fantastic seal life for notoriously difficult application

Over a million US gallons of water saved

LabTecta seals solve leakage problems

LabTecta saving time and money at US plant

Double seals bring major savings for Michigan firm

Mining company saves $8 million AUD with AESSEAL system

Price and lead time more than halved

6 times improvement in MTBF for Upstream water injection pump

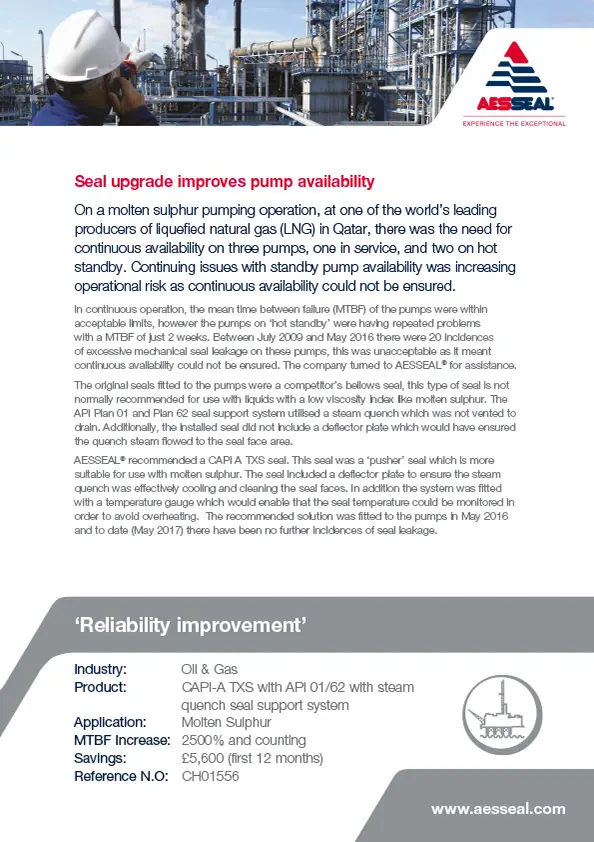

Seal upgrade improves pump availability

Offshore oil and gas company calls in AESSEAL for bearing protection

AES-Elast™ successfully replaces leading brand

FDA compliant elastomer increases reliability

Chemical plant saved over €500,000 in the first year

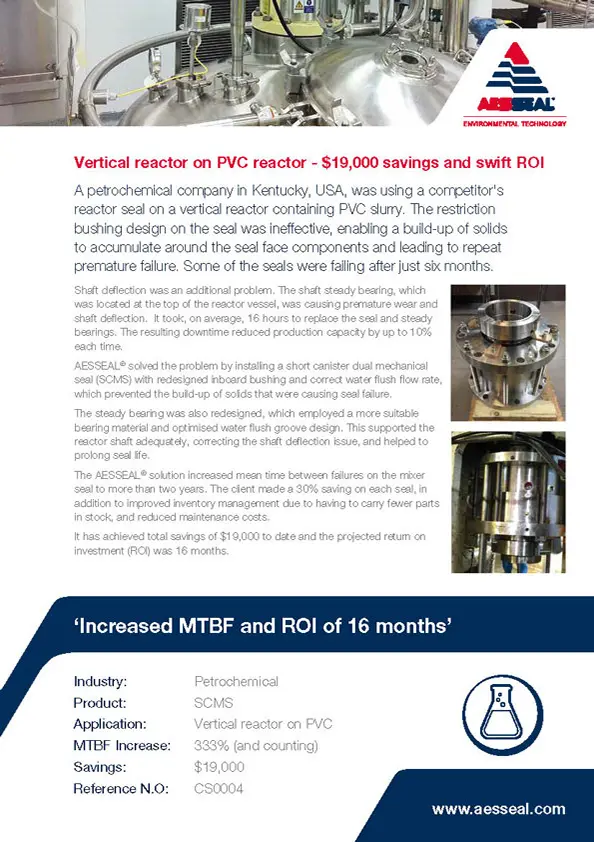

Vertical reactor on PVC reactor - $19,000 savings and swift ROI

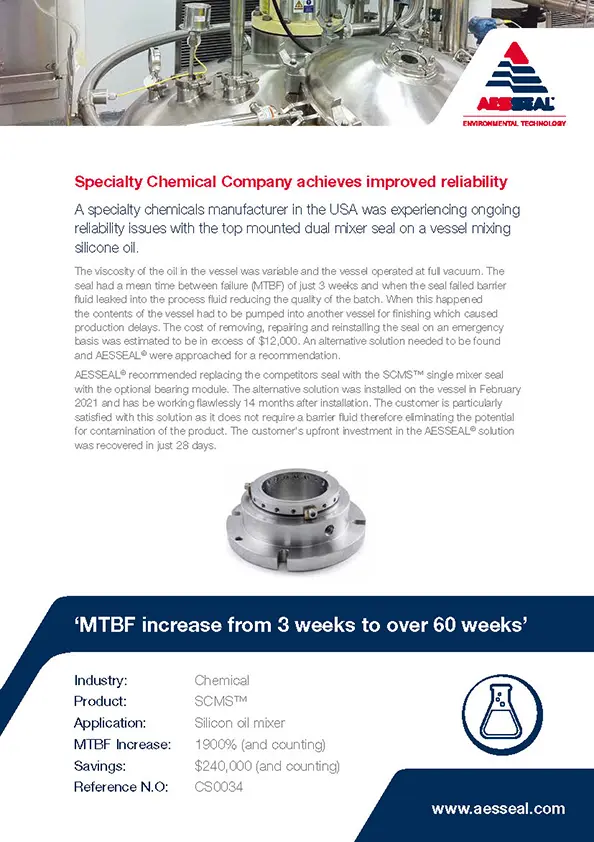

Specialty Chemical Company achieves improved reliability

Cleaner plant with AESSEAL gland packing

Quality of service key to AESSEAL contract

LabTecta eliminates oil leakage

Success with bad actor pump leads to further opportunity

LabTecta upgrade increases MTBF from 2 weeks to 2 years and counting

Quality service and technical support for South African contract

Change to AESSEAL helps reduce filter downtime

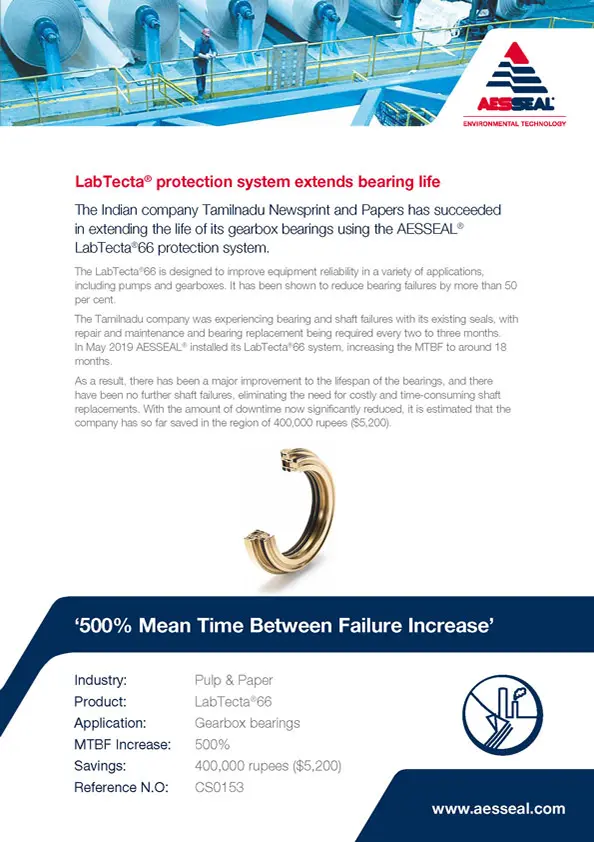

LabTecta protection system extends bearing life

The AESSEAL DMSF helps cut water usage for US company

Trapezoidal Packing Improves Reliability

Increased reliability with AESSEAL bearing protection

Solution delivers $17,000 inventory cost savings

Five times improvement in reliability

Reliability Improved For Waste Energy Company

Reliability upgrade saves over ZAR200,000 in just 10 months of operation

Reliable solution for high pressure, high temperature agitator application

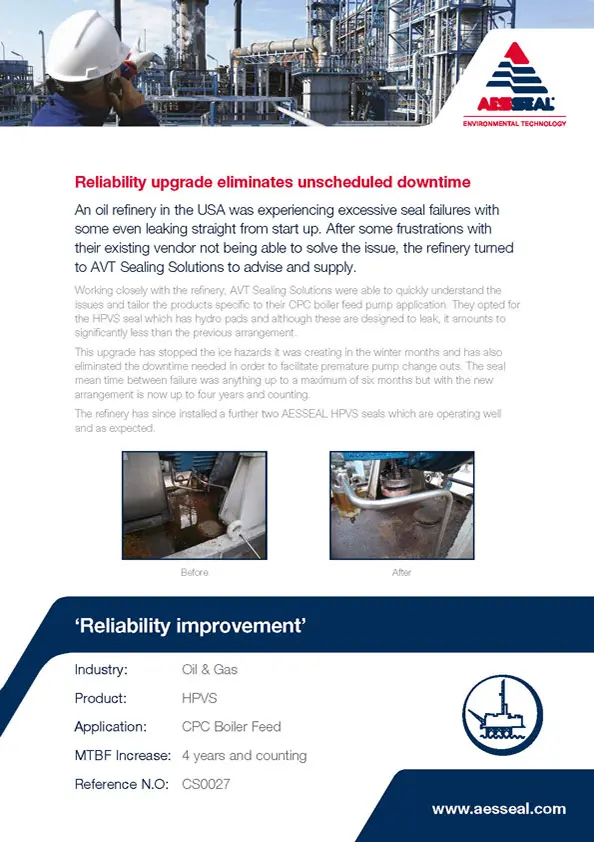

Reliability upgrade eliminates unscheduled downtime

Trapeziodal Packing improves reliability 3-fold

Navy reduces repair times and improves pump reliability

Trialling different solutions to improve MTBF

Successful Support System Upgrade Improves Plant Reliability

Reliability upgrade reduces seal repair costs

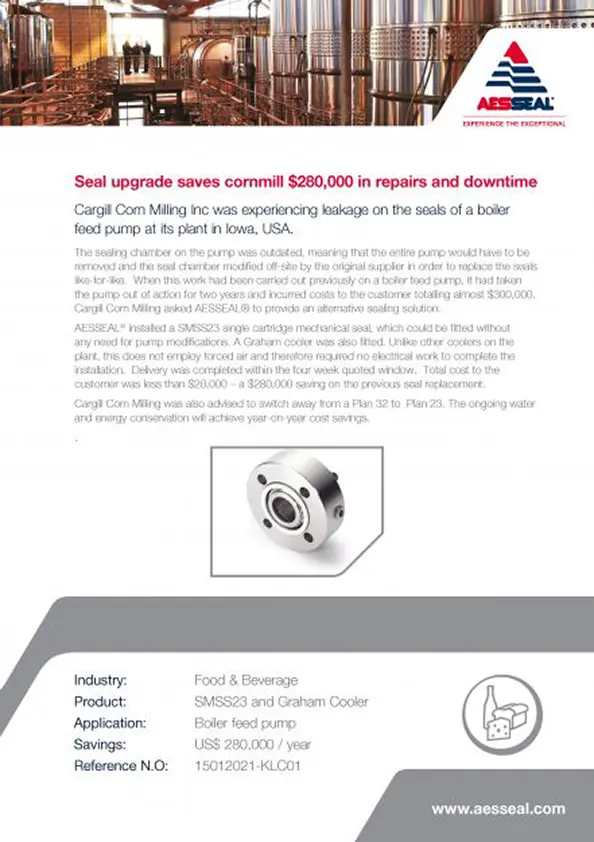

Seal upgrade saves cornmill $280,000 in repairs and downtime

Chemical Producer Saves Over £1.7 Million in Plant Downtime

MTBF increases by 233%

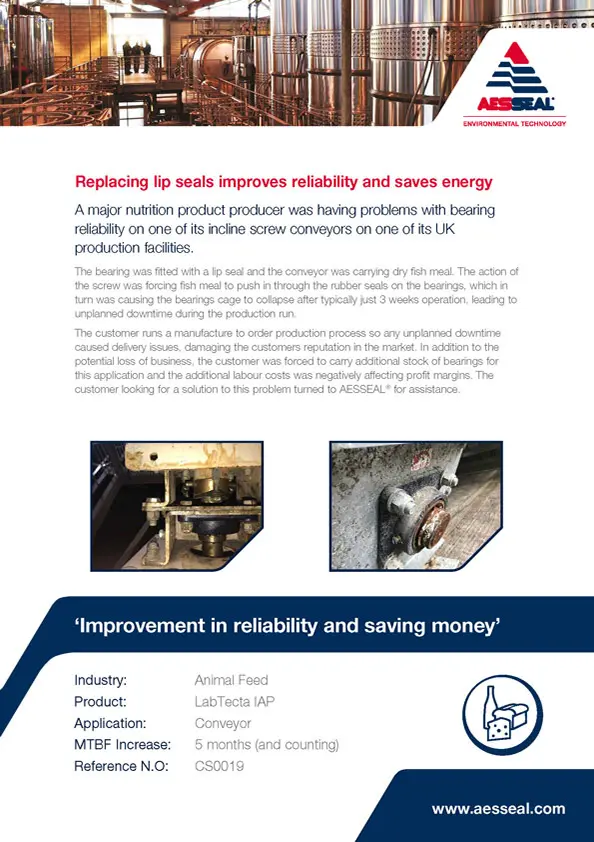

Replacing lip seals improves reliability and saves energy

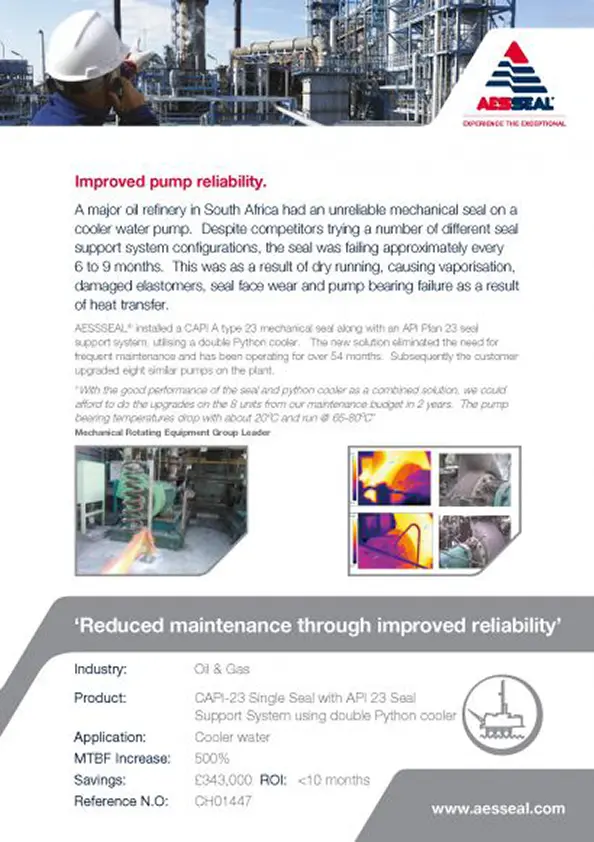

Improved pump reliability for oil refinery

Chemical company saves £9,400 and 17,000m3 of water a year

Bearing protection increases mean time between failure

Zinc Smelting Plant Saves Thousands

Paper producer saves more than one million Dollars per year

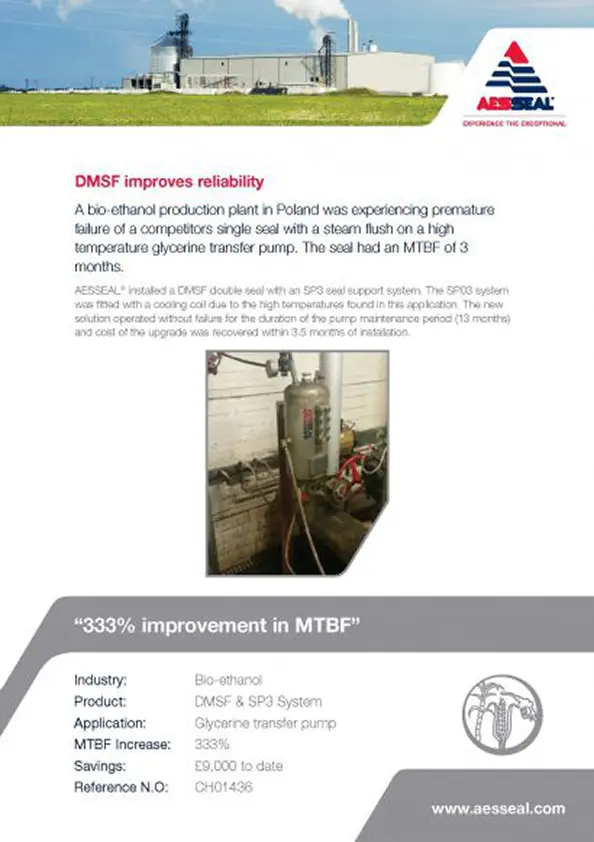

DMSF improves reliability

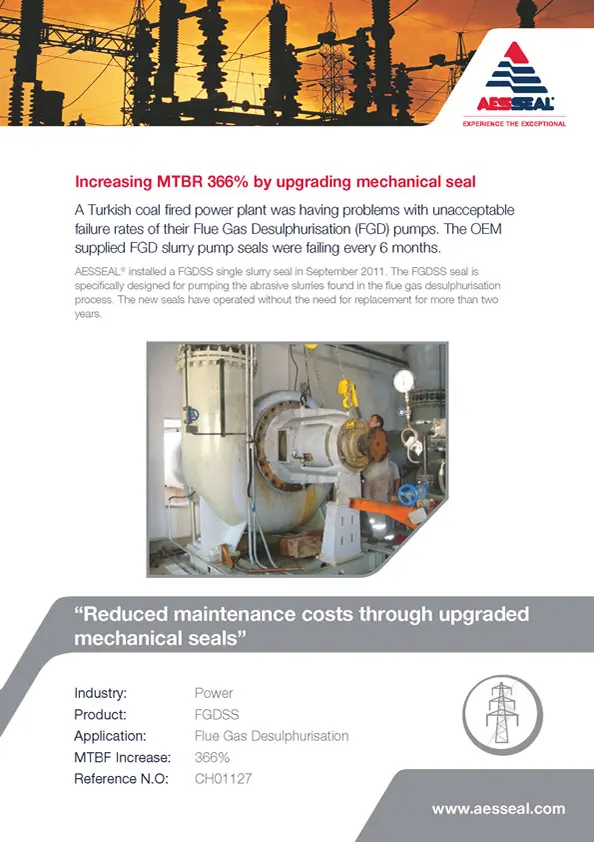

Increasing MTBR 366% by upgrading

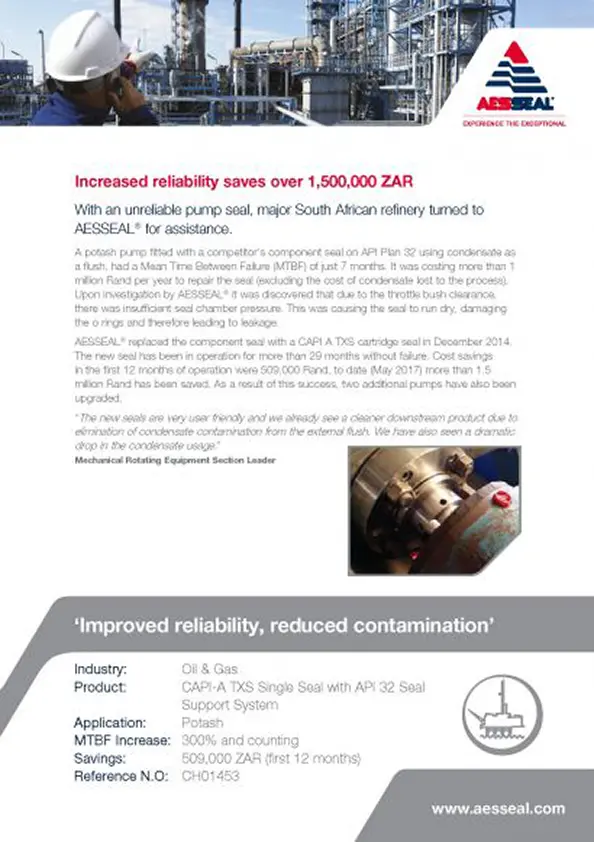

Increased reliability saves over 1,500,000 ZAR

Upgrading component seals with M0FCA plug-in seals

One of the largest dairies in Ireland is upgrading from industry standard component type seals to AESSEAL M0FCA unitized plug-in seals after a successful 4 and a half year trial.

Successfully sealing cooling tower motors at Dairy Crest

Mondi Meets Sustainability Targets

7 years trouble free bearing protection

Dry Gas Seal improves reliability and leads to a major overhaul program

5 years without failure and a ZAR3.2million saving

An upgrade to LabTecta-PB gives a 500% MTBF increase

540% increase in MTBF rates