Installation Help Case Studies

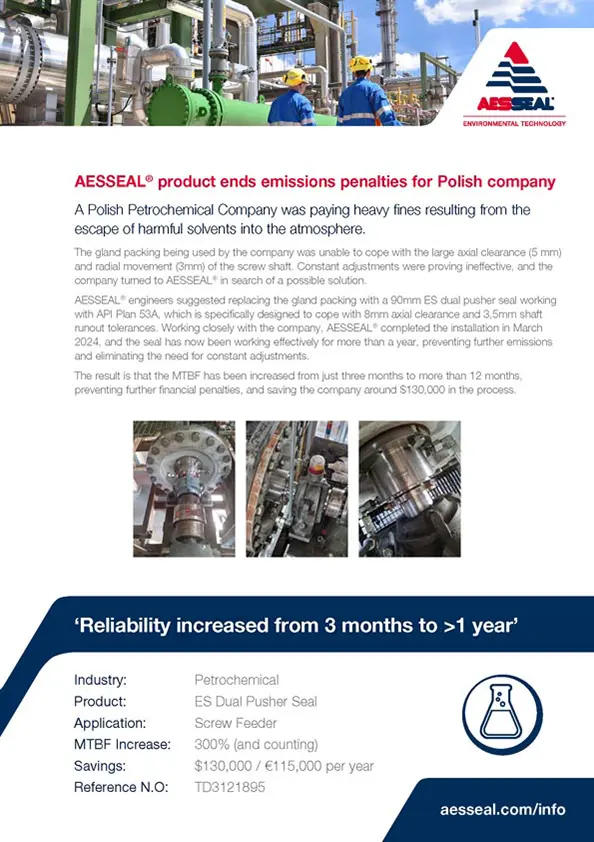

AESSEAL product ends emissions penalties for Polish company

AESSEAL 380TP solves leakage problem at Yorkshire factory

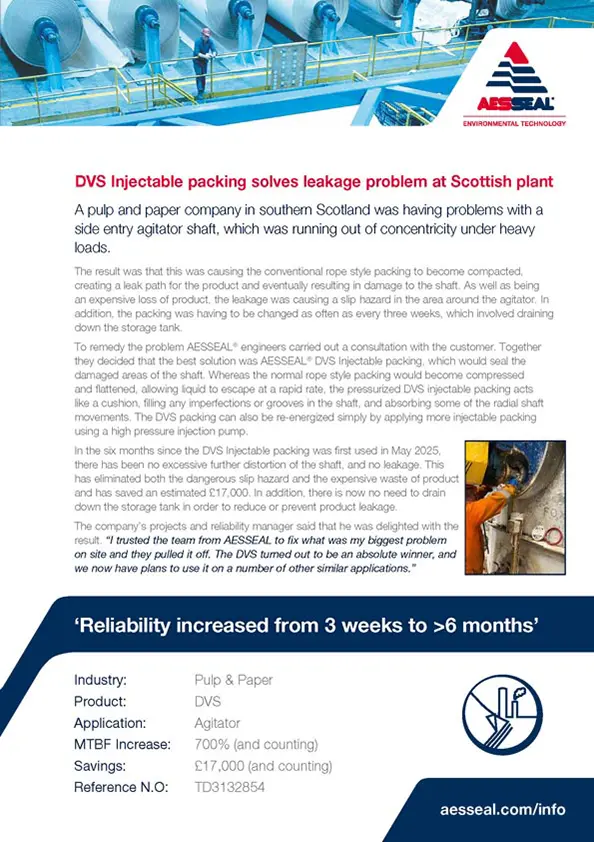

DVS Injectable packing solves leakage problem at Scottish plant

CURC puts an end to leakage problem

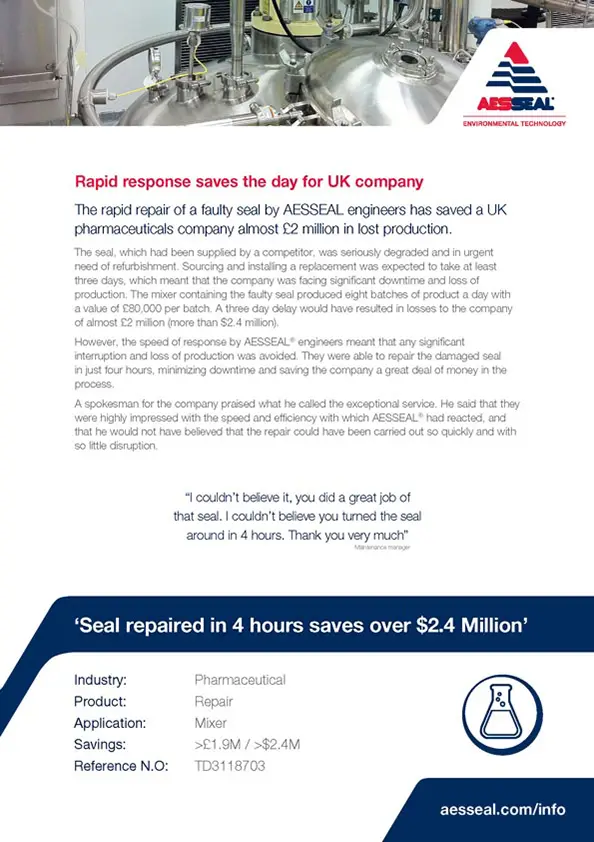

Rapid response saves the day for UK company

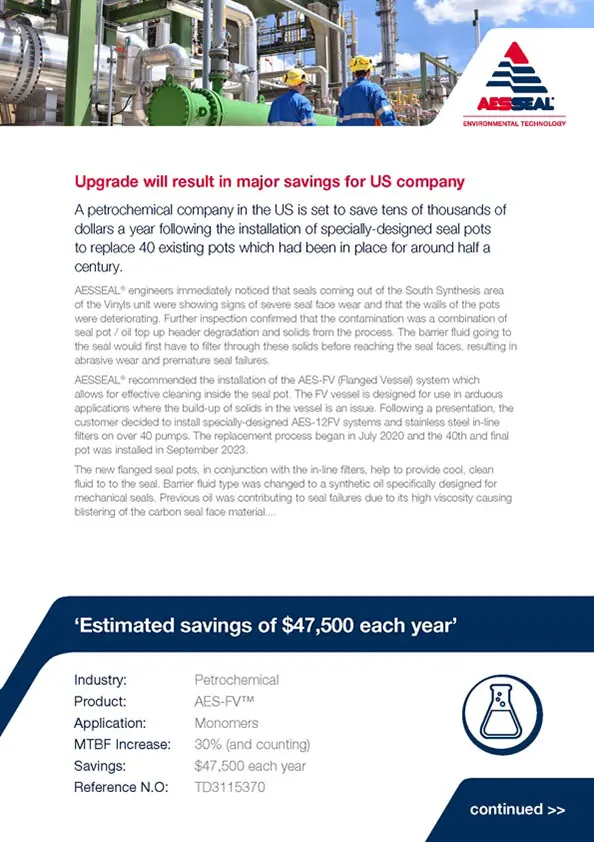

Upgrade will result in major savings for US company

Superior AESSEAL product and service seals the deal

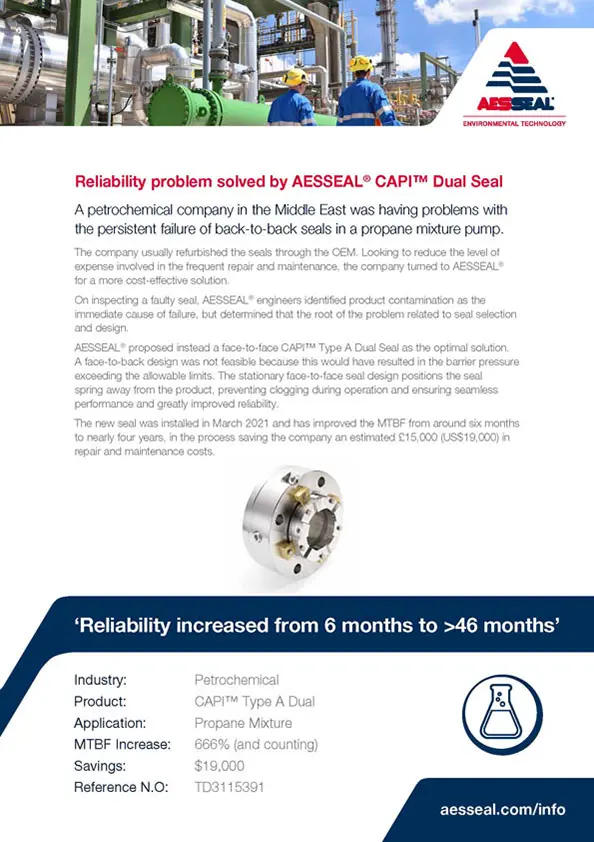

Reliability problem solved by AESSEAL CAPI Dual Seal

Major savings for SA company

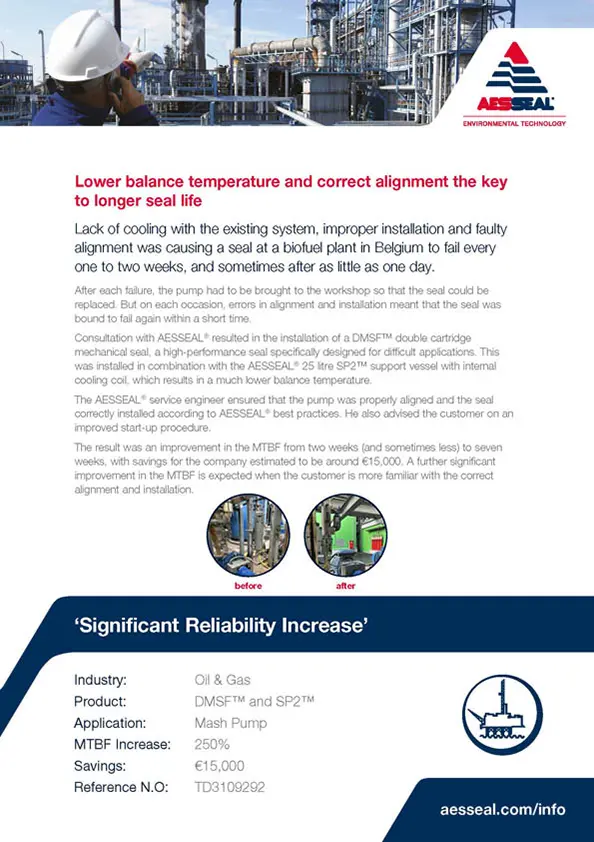

Lower balance temperature and correct alignment the key to longer seal life

Swedish plant makes savings with DMSF

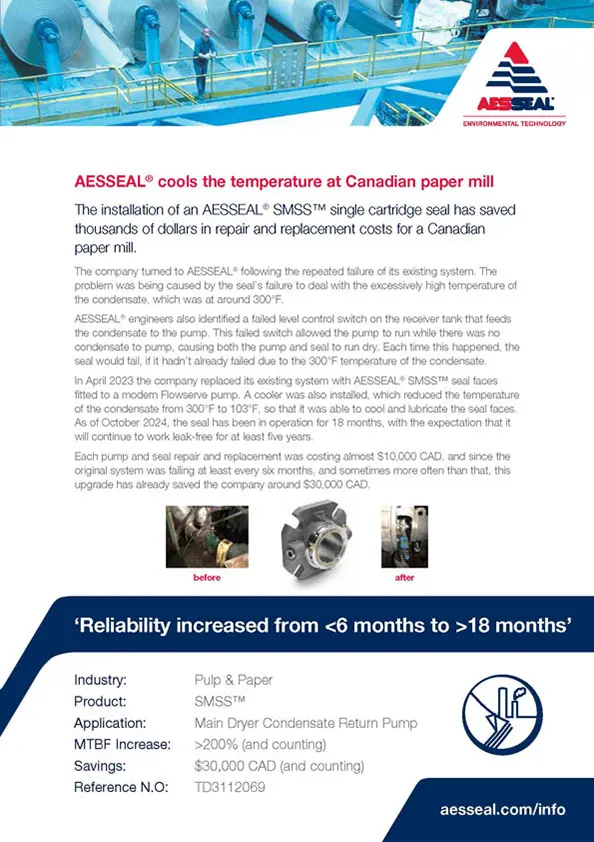

AESSEAL cools the temperature at Canadian paper mill

STS seal and LabTecta ST ends steam leak hazard

Huge savings at Austrian steel mill

AESSEAL repair saves thousands for Saudi company

DMSF ends leakage problem for Saudi firm

AESSEAL product removes risk of HFC emissions

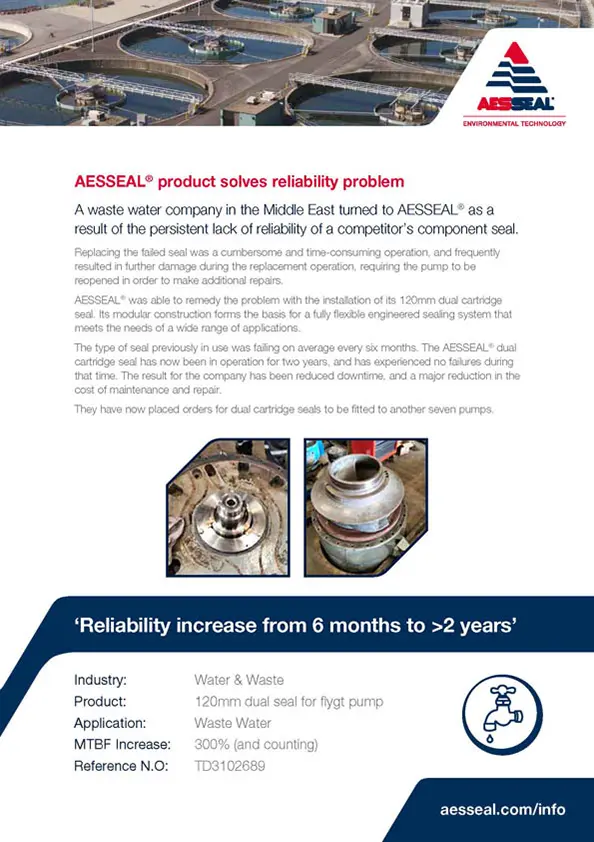

AESSEAL product solves reliability problem

LabTecta reduces repair costs for Portuguese mining company

CKSA seal ensures reliability for UAE company

CDPH & EasyClean boosts MTBF from four months to seven years

AESSEAL packing guarantees highest food quality

Major savings for Algerian food producer

CURC solves reliability problem for SA company

AESSEAL ES the choice for easy installation

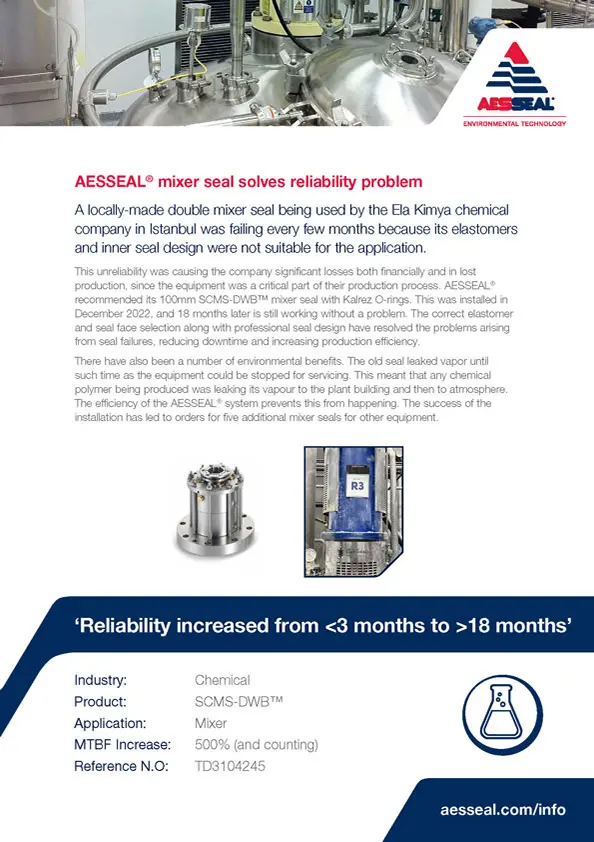

AESSEAL mixer seal solves reliability problem

A locally-made double mixer seal being used by the Ela Kimya chemical company in Istanbul was failing every few months because its elastomers and inner seal design were not suitable for the application.

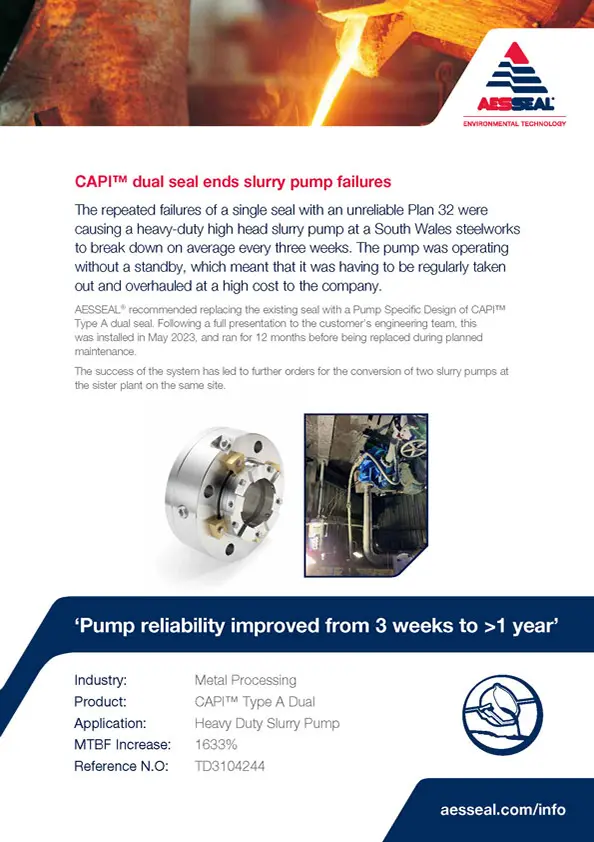

CAPI dual seal ends slurry pump failures

The repeated failures of a single seal with an unreliable Plan 32 were causing a heavy-duty high head slurry pump at a South Wales steelworks to break down on average every three weeks.

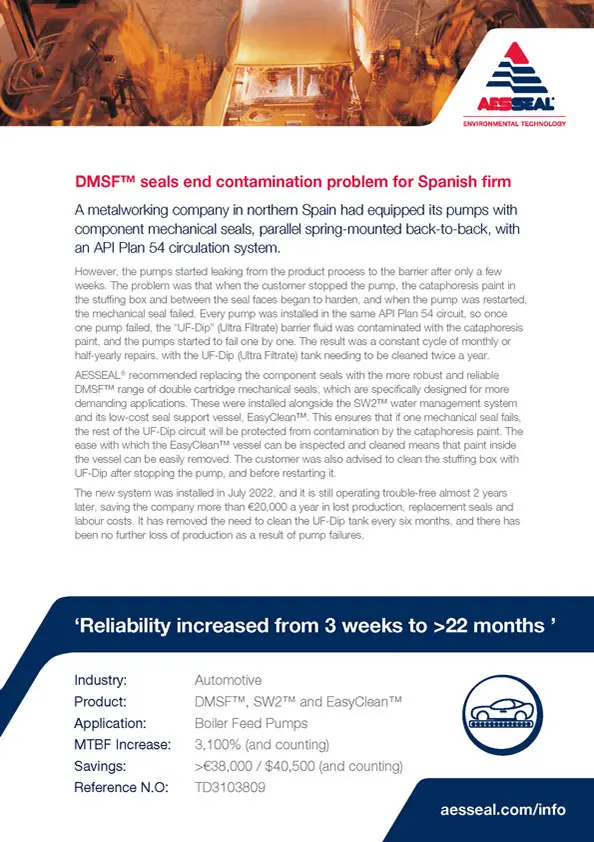

DMSF seals end contamination problem for Spanish firm

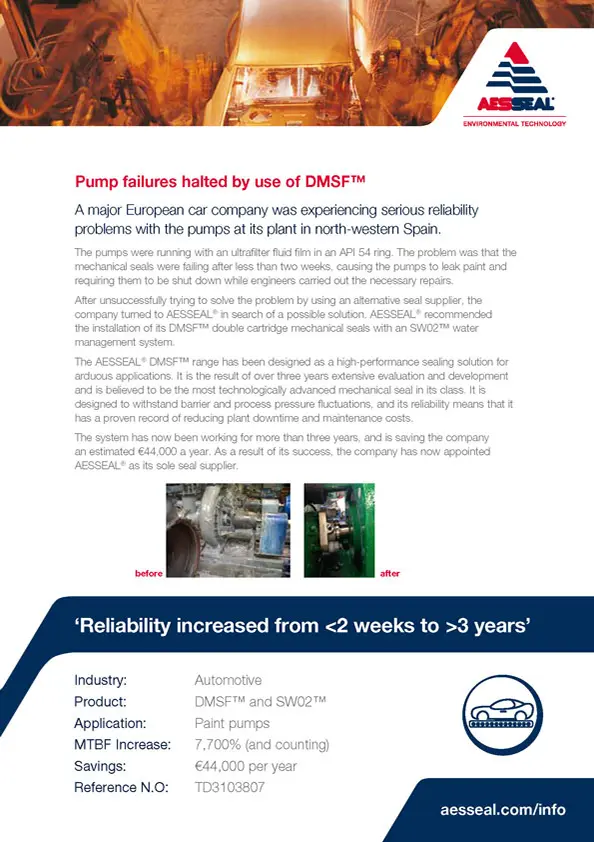

Pump failures halted by use of DMSF

A major European car company was experiencing serious reliability problems with the pumps at its plant in north-western Spain.

Autoclave specialist chooses AESSEAL for reliability and customer service

A Turkish phosphate fertiliser was established following a requirement for Turkey to produce most its own phosphate fertiliser.

Improved reliability for Flygt pump

A water utility company in the United Arab Emirates were dissatisfied with the performance of the mechanical seals in its Flygt pump.

Major savings follow installation of AESSEAL product

A petrochemical company based in the Middle East was having problems with persistent and costly seal failures.

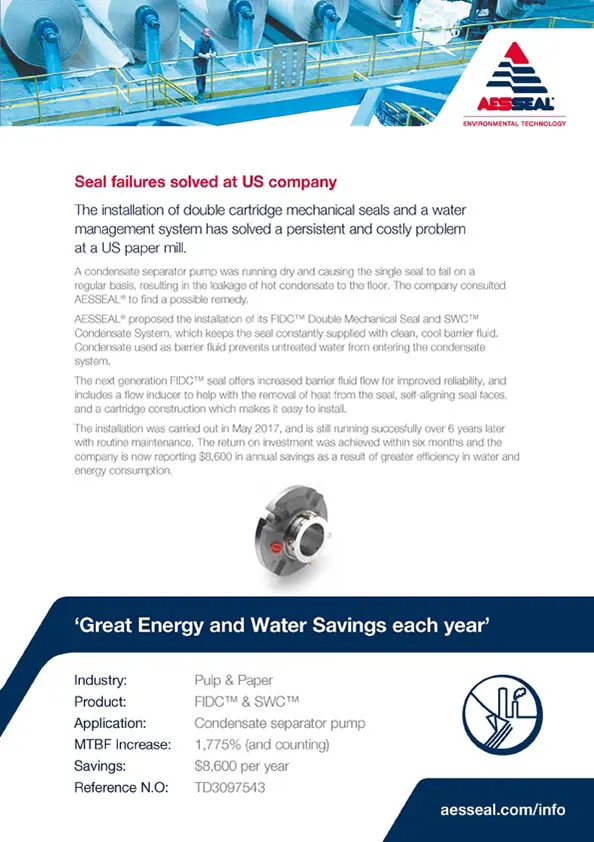

Seal failures solved at US company

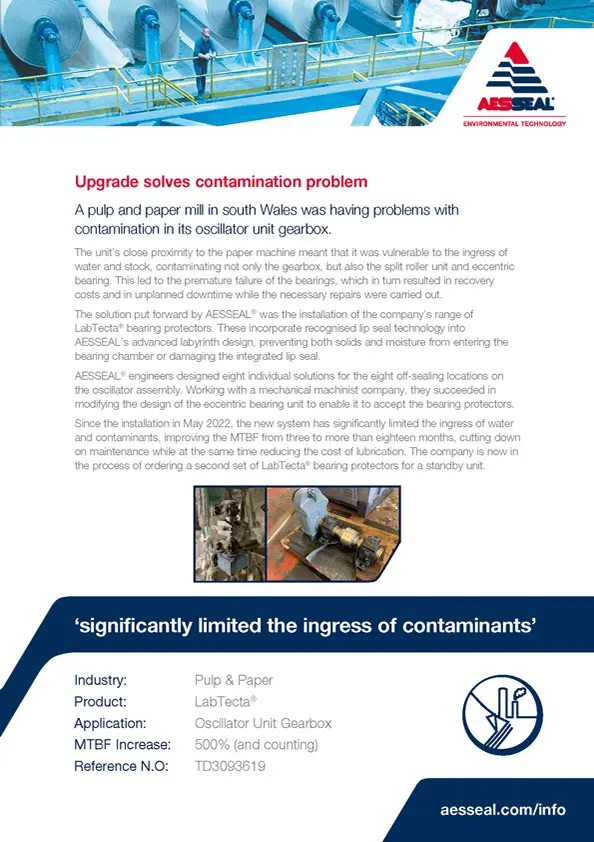

Upgrade solves contamination problem

Huge savings after LabTecta installation

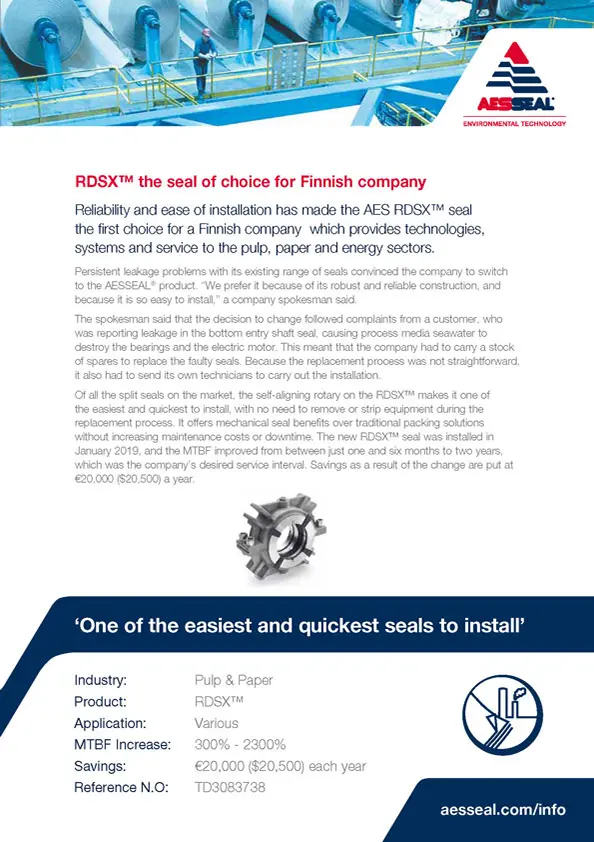

RDSX the seal of choice for Finnish company

Solar energy component manufacturer increases MTBF

AESSEAL system eliminates danger of hydrogen sulfide release

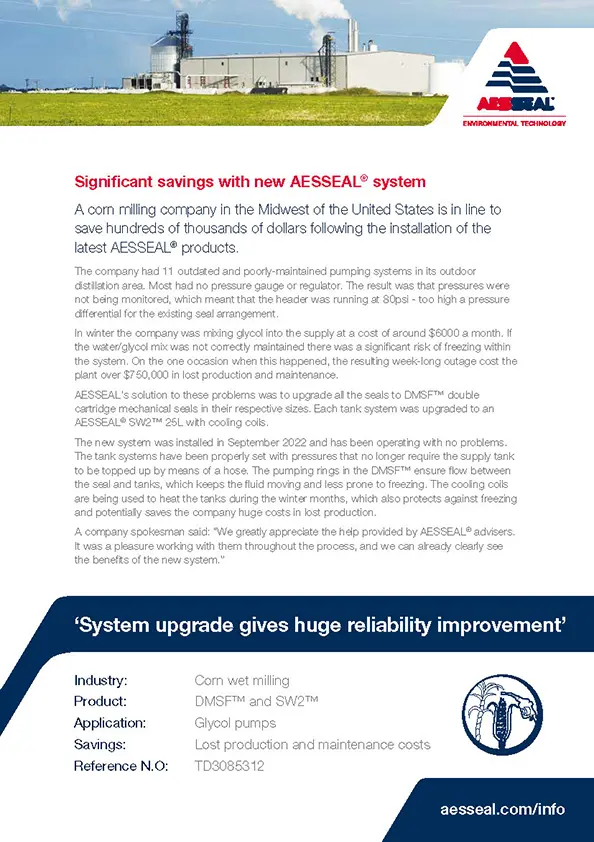

Significant savings with new AESSEAL system

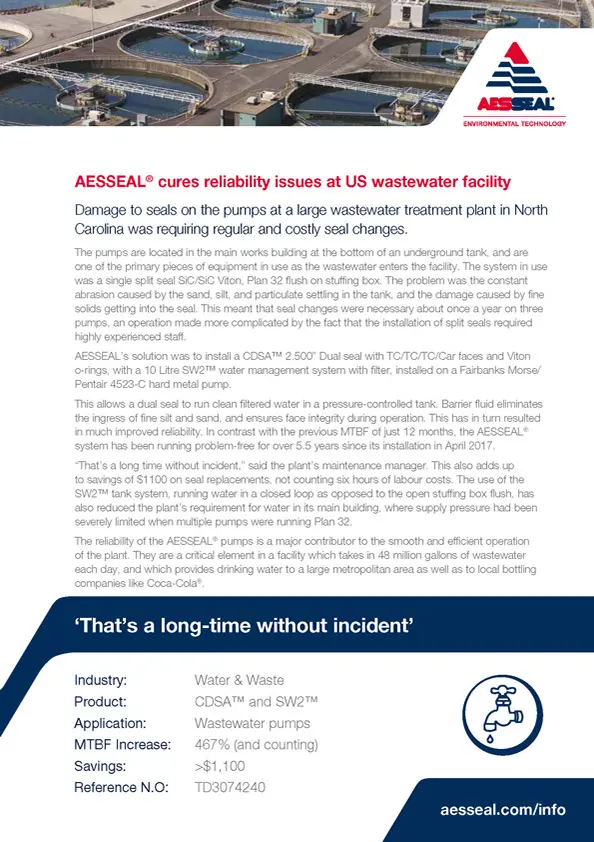

AESSEAL cures reliability issues at US wastewater facility

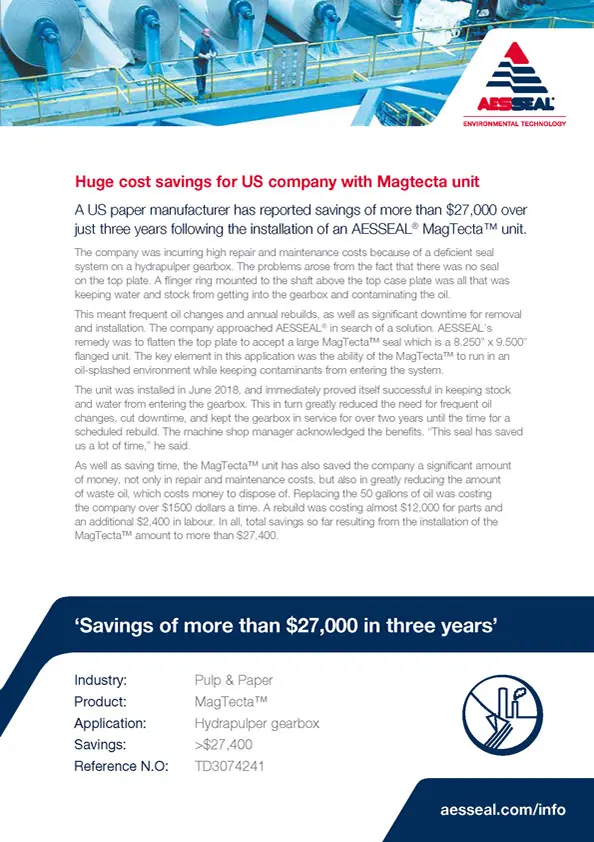

Huge cost savings for US company with Magtecta unit

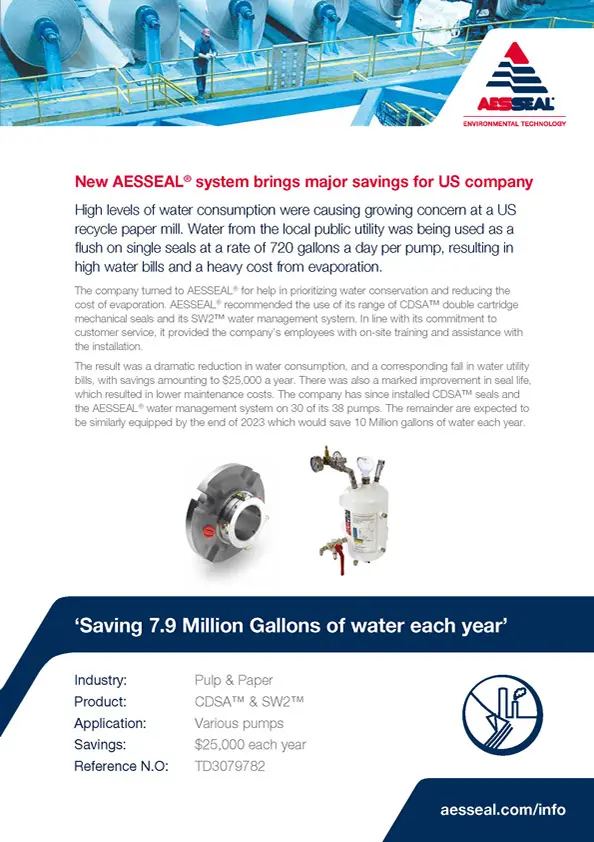

New AESSEAL system brings major savings for US company

Price and lead time more than halved

AESSEAL system eases cost pressures for African company

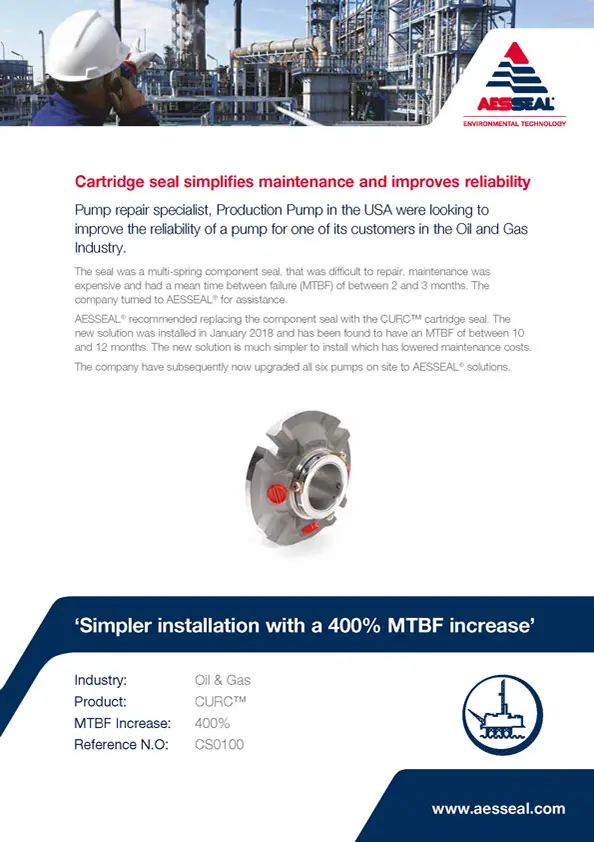

Cartridge seal simplifies maintenance and improves reliability

Improved reliability for new process

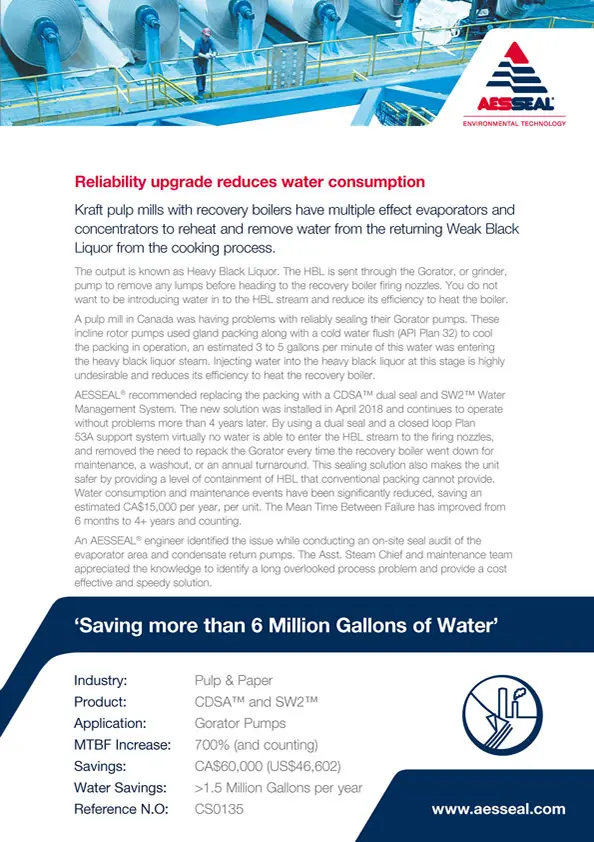

Reliability upgrade reduces water consumption

Lip seal upgrade for US petrochemical plant

AESSEAL product solves seal failure problem

Seal upgrade improves pump availability

Fast delivery, reliable solutions.

LabTecta delivers reliability improvement

Offshore oil and gas company calls in AESSEAL for bearing protection

Eliminating over 61 million gallons of water from 26 evaporator pumps

9+ Years MTBF for condensate pump

Quality service and technical support for South African contract

Change to AESSEAL helps reduce filter downtime

New seal design the difference at US firm

AESSEAL SW system solves water pressure problem

New seals overcome persistent leakage

AESSEAL product aids major cuts to water usage

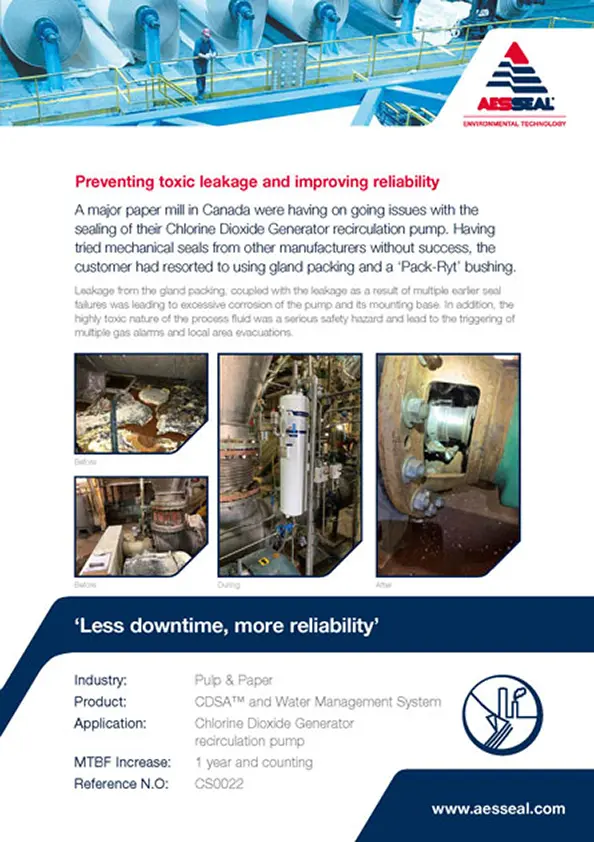

Preventing toxic leakage and improving reliability

Solution delivers $17,000 inventory cost savings

Mechanical seals runs an incredible 17 years without problems

Mechanical Seal upgrade improve reliability and saves more than ZAR 580,000

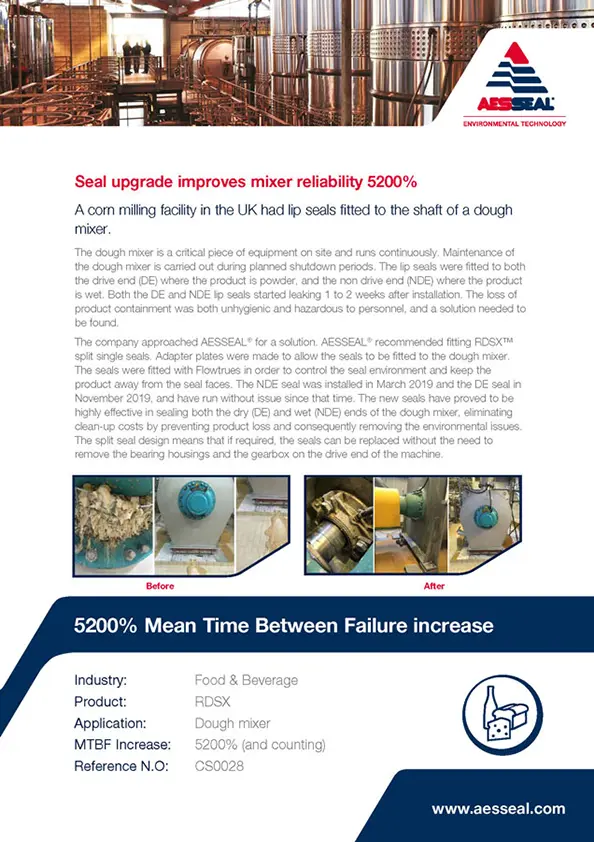

Seal upgrade improves mixer reliability 5200%

Reliability Improved For Waste Energy Company

Seal upgrade improves reliability and simplifies maintenance

Reliability upgrade eliminates unscheduled downtime

Massive water savings with improved reliability

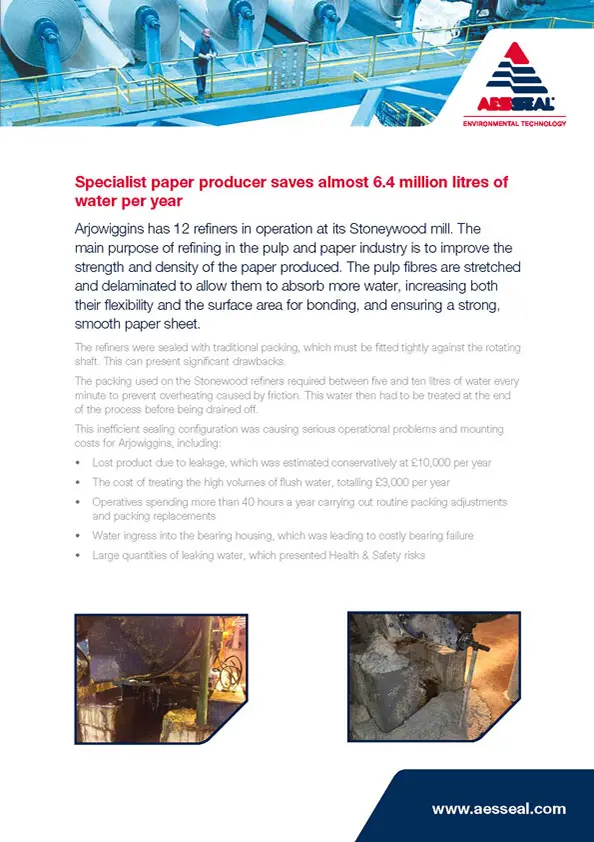

Specialist paper producer saves almost 6.4 million litres of water per year

Reliable solution for high pressure, high temperature agitator application

Navy reduces repair times and improves pump reliability

Trialling different solutions to improve MTBF

Tailored seal solution cuts costs and operational downtime

Seal upgrade saves cornmill $280,000 in repairs and downtime

Unique solution saves $287,000 a year and improves safety

MTBF increases by 233%

Counterproductive flush water in an evaporator pump leads to big savings

Replacing lip seals improves reliability and saves energy

80 million litres of water per year to be saved at Mexican mine

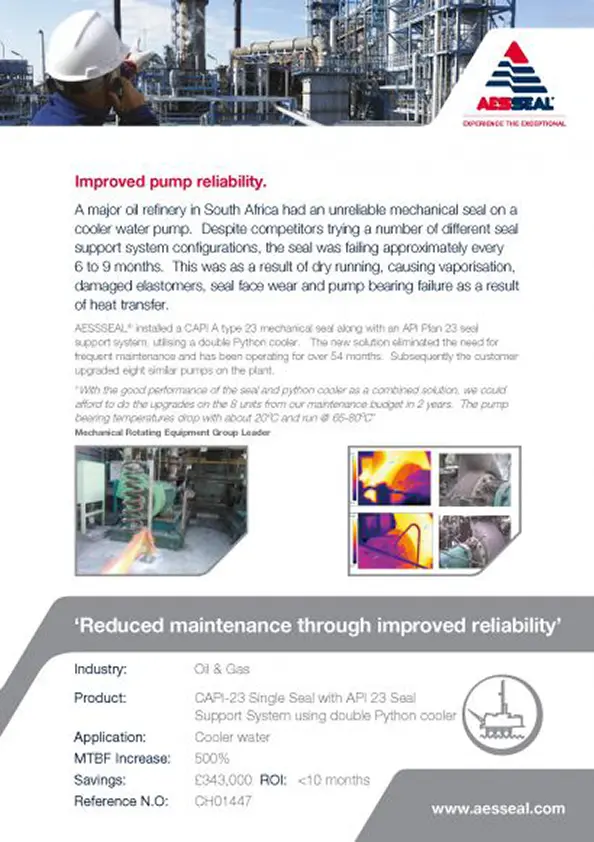

Improved pump reliability for oil refinery

Reduced maintenance and water consumption at Iron Ore Mine

Bearing protection increases mean time between failure

ROI In Less Than A Month

UK pulp and paper mill upgrade lip seals for bearing protection

Failing bearings thing of the past for German paper mill

DMSF improves reliability

Training and support leads to reliability

Huge cost savings and improved reliability with gland packing upgrade

Increased reliability saves over 1,500,000 ZAR

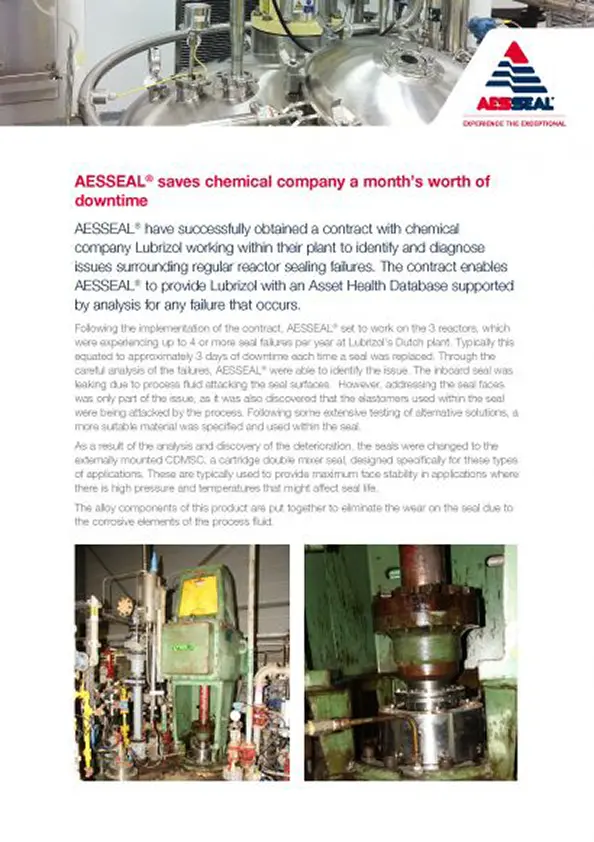

Chemical company saves a months worth of downtime

Upgrading component seals with M0FCA plug-in seals

One of the largest dairies in Ireland is upgrading from industry standard component type seals to AESSEAL M0FCA unitized plug-in seals after a successful 4 and a half year trial.

DMSF upgrade saves over £460,000 a year

5 years without failure and a ZAR3.2million saving