Safety Improvements Case Studies

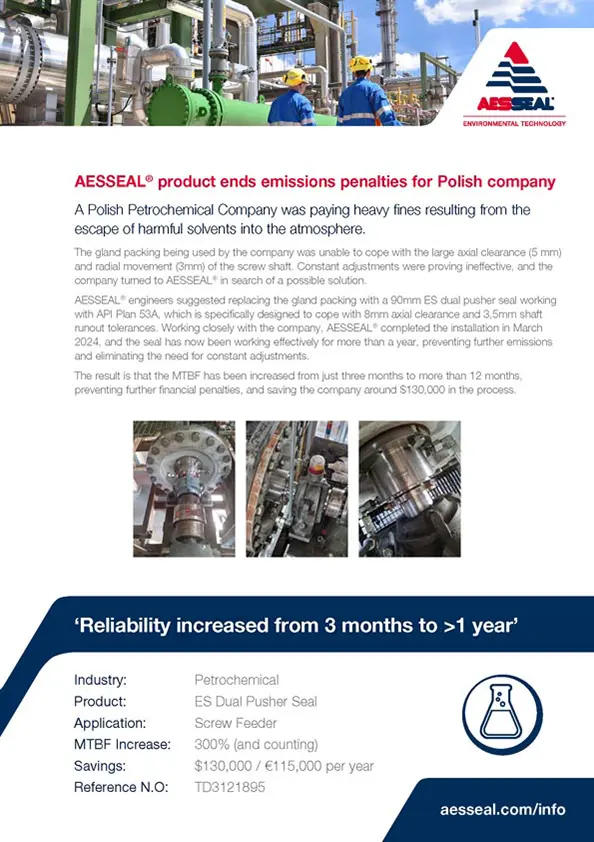

AESSEAL product ends emissions penalties for Polish company

AESSEAL 380TP solves leakage problem at Yorkshire factory

DVS plugs the leaks at UK sugar factory

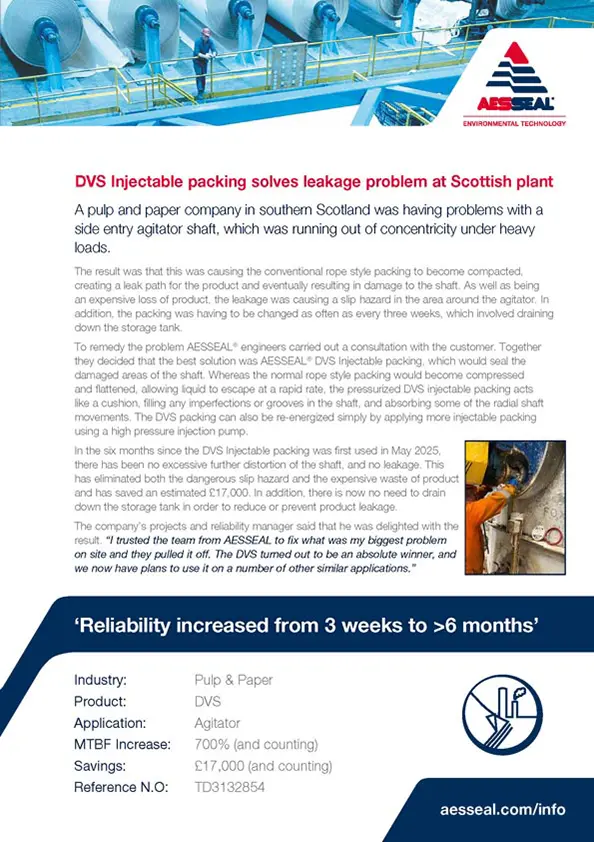

DVS Injectable packing solves leakage problem at Scottish plant

AESSEAL packing puts an end to costly leaks

AESSEAL cleans up the brown lagoon

A sugar company in the English Midlands has saved more than £40,000 following a decision to upgrade its packing system to the AESSEAL® trapezoidal cross-section packing AESSEAL® 380TP.

LabTecta puts a stop to eight-year oil leaks

CURC solves leakage problem for Saudi company

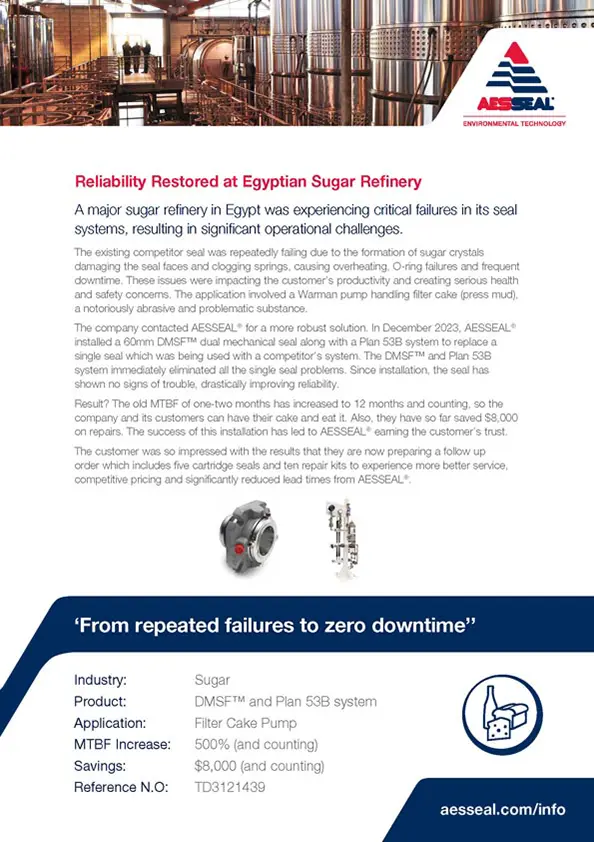

Reliability restored at Egyptian sugar refinery

DMSF seal saves thousands for Australian company

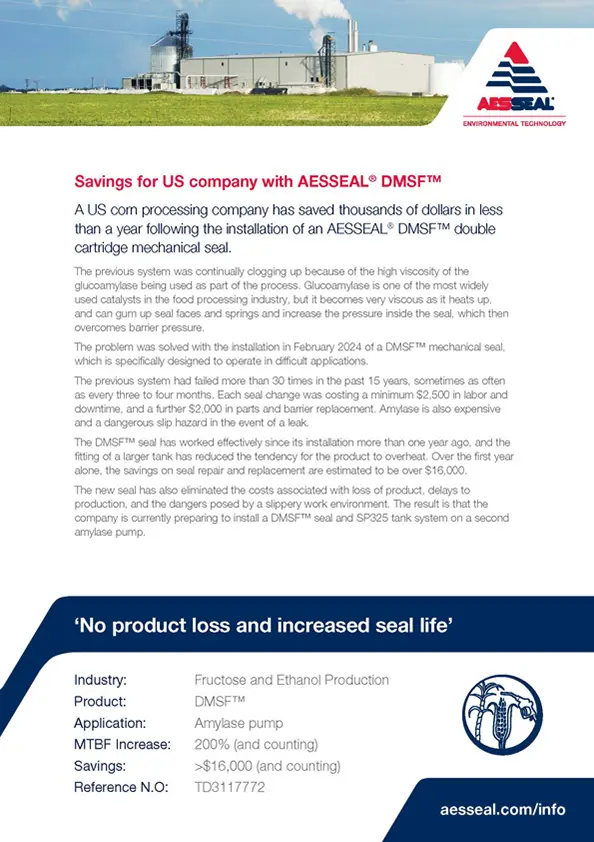

Savings for US company with AESSEAL DMSF

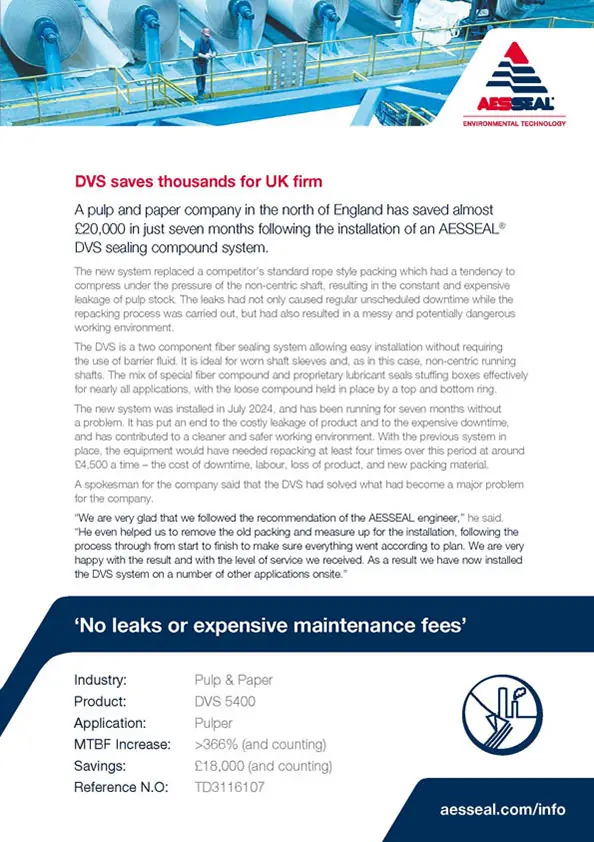

DVS saves thousands for UK firm

Superior AESSEAL product and service seals the deal

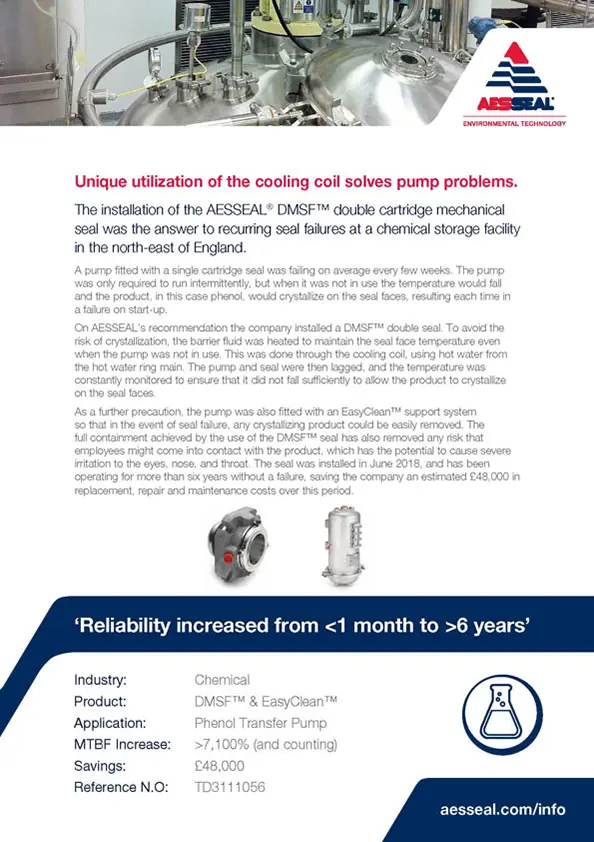

Unique utilization of the cooling coil solves pump problems.

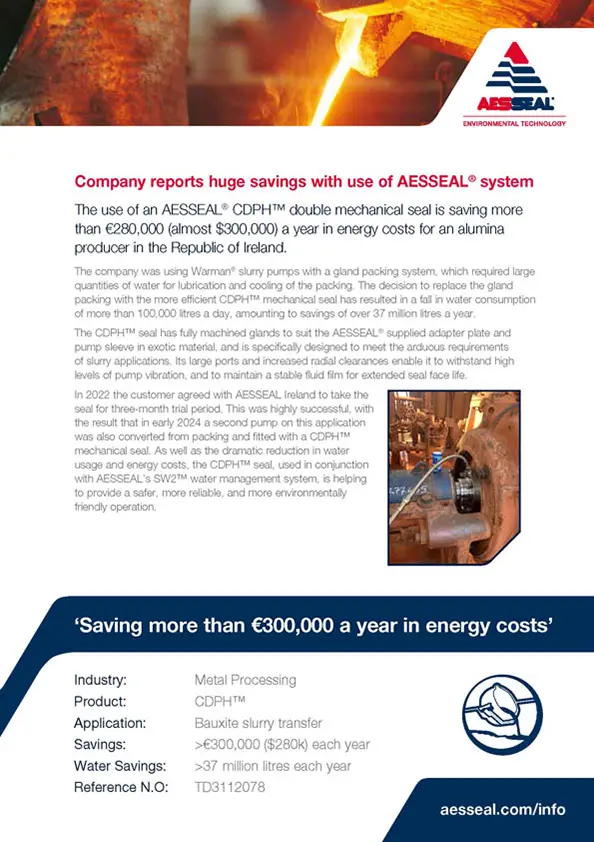

Company reports huge savings with use of AESSEAL system

DMSF solves reliability issues for Swedish company

CDSA provides major savings for German company

Seal still giving perfect service after more than ten years

STS seal and LabTecta ST ends steam leak hazard

FIDC cleans up at salt plant

LabTecta saves €360,000 for Spanish company each year

Dangerous oil leak problem solved by LabTecta FS

DMSF ends leakage problem for Saudi firm

AESSEAL CURC stops leaks at sewage treatment plant

The installation in December 2022 of an AESSEAL® CURC™ single seal proved to be the remedy for serious issues at a sewage treatment facility in the Middle East.

CDM ends seal failures for German company

Major savings with CKD double seal

FIDC ends costly leaks at US firm

AESSEAL product removes risk of HFC emissions

Major US food producer opts for AES-Elast

CDSA makes for safer workplace

AESSEAL solves reliability problems for paper company

AESSEAL packing guarantees highest food quality

CSSN guarantees water supply for Spanish town

Spanish company cuts costs with CURC

EasyClean cuts water usage at French milk plant

Installation of the EasyClean™ water management system helped French milk production company to improve its hygiene standards and reduce water usage.

AESSEAL mixer seal solves reliability problem

A locally-made double mixer seal being used by the Ela Kimya chemical company in Istanbul was failing every few months because its elastomers and inner seal design were not suitable for the application.

DMSC is worth its salt

A poorly-designed seal was causing problems for a major salt producer in eastern France.

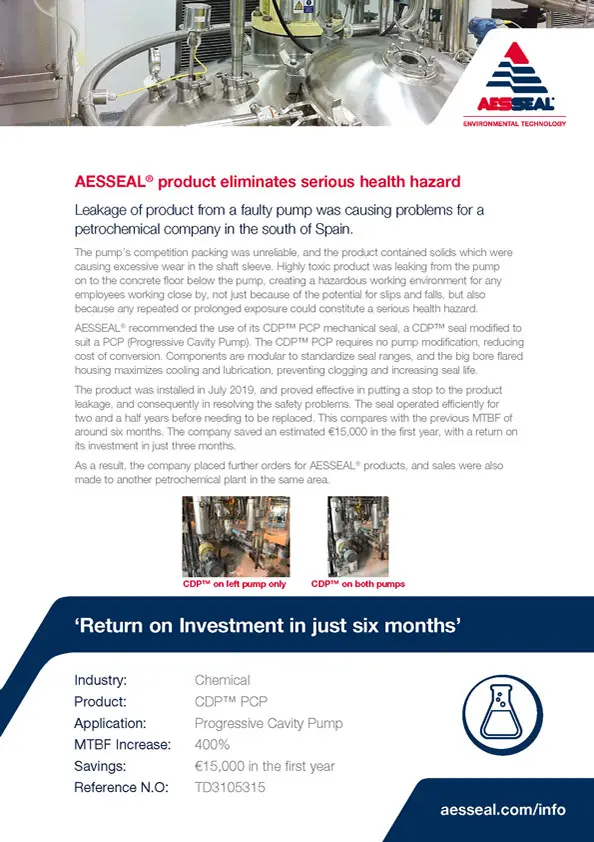

AESSEAL product eliminates serious health hazard

Leakage of product from a faulty pump was causing problems for a petrochemical company in the south of Spain.

AES-Elast the answer to seal selection problem

Employees at William Grant’s Scottish whisky distillery in Girvan, Ayshire, were having difficulty selecting the correct mechanical seals for specific applications.

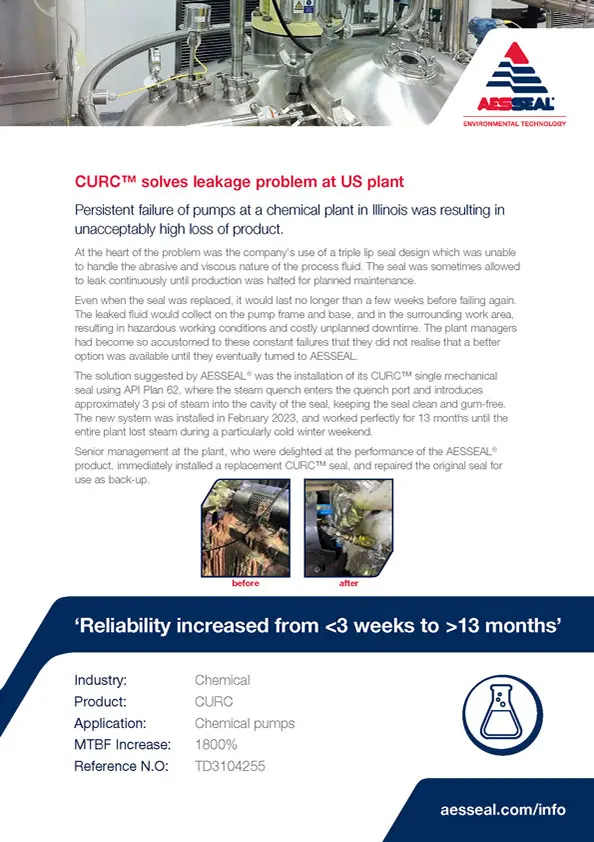

CURC solves leakage problem at US plant

Persistent failure of pumps at a chemical plant in Illinois was resulting in unacceptably high loss of product.

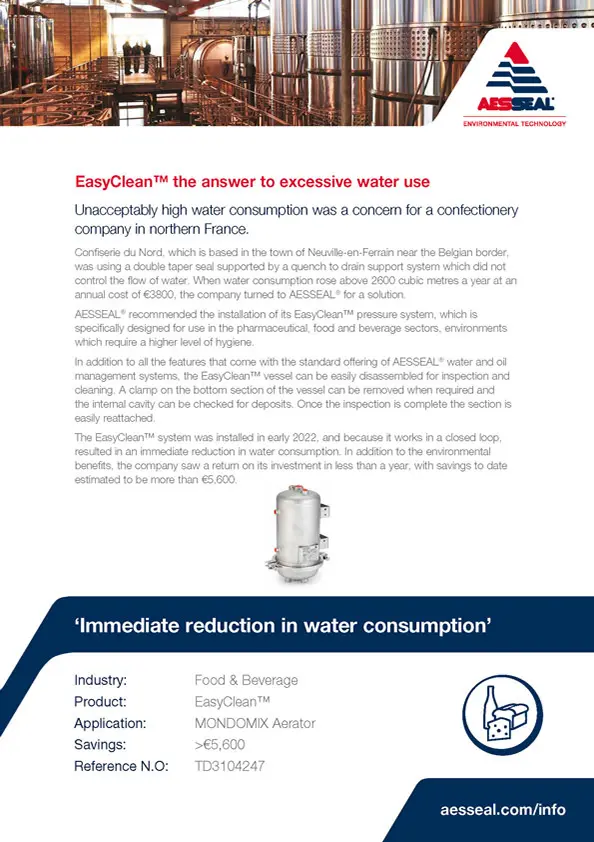

EasyClean the answer to excessive water use

Unacceptably high water consumption was a concern for a confectionery company in northern France.

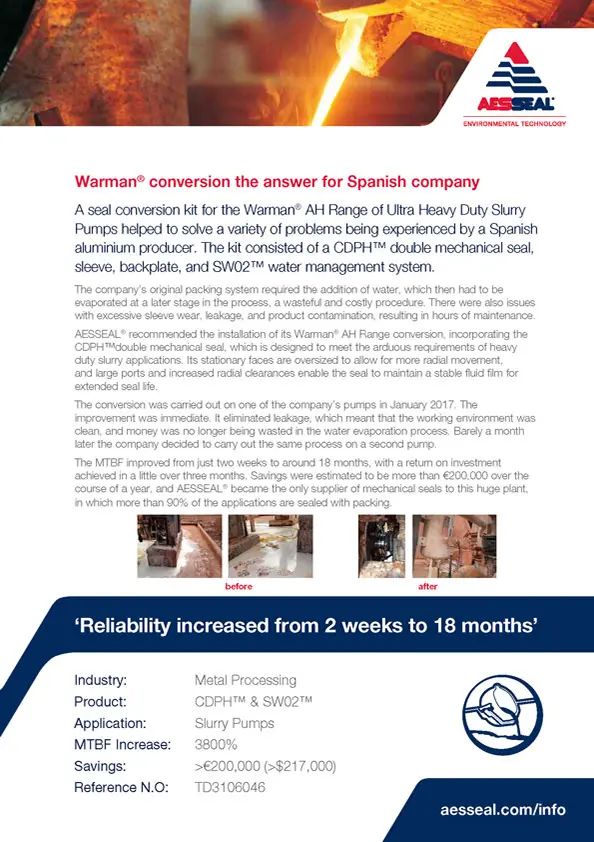

Warman conversion the answer for Spanish company

A seal conversion kit for the Warman® AH Range of Ultra Heavy Duty Slurry Pumps helped to solve a variety of problems being experienced by a Spanish aluminium producer.

LabTecta the remedy for lip seal failures

The lip seals in use at a north of England glass manufacturer were wearing out after just a few weeks

Safety and reliability with AESSEAL heavy duty seal

A mining company in Australia was facing persistent problems from seal failures on one of its slurry pumps.

Bitumen pump upgrade saves over £23,000 a year

Asphalt producer pump for road surfaces was gland packed and losing over 15 tonnes of bitumen.

DMSF seals end contamination problem for Spanish firm

AESSEAL upgrade removes safety risk

AESSEAL system fixes sewage problems for US township

A municipality in Pennsylvania was having issues with major inefficiencies in its sewage treatment system.

AVT sensors save thousands for US company

Excessive vibrations in a vertical pump in a slurry pit application was leading to failure every month for the North Carolina company Befesa

AESSEAL cuts water usage by 75 percent at US company

A US mining company was concerned that its large end suction pumps were using excessive amounts of water.

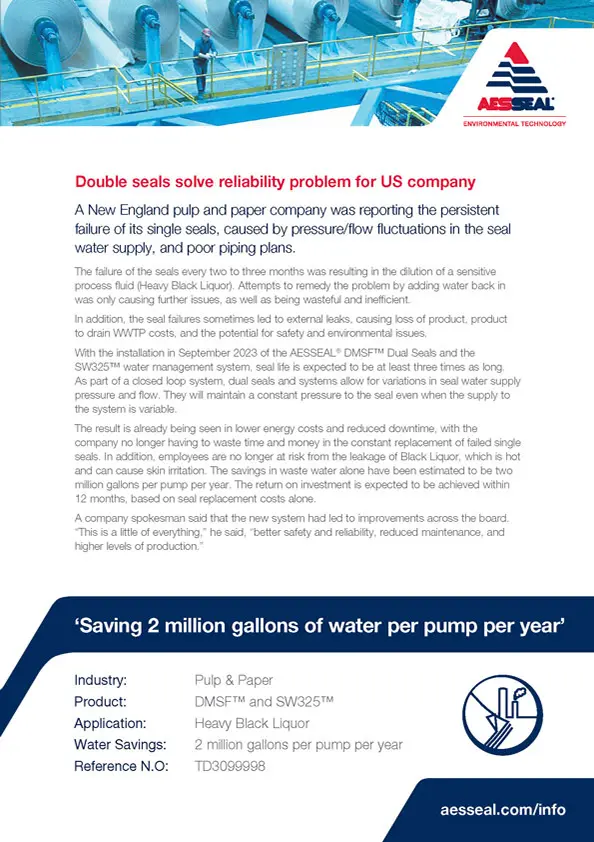

Double seals solve reliability problem for US company

A New England pulp and paper company was reporting the persistent failure of its single seals

Improved reliability using dual seal and system

A corn wet milling plant in the USA had a problem with leaking seals on the centrifugal pumps.

Standard of service makes AESSEAL a clear winner

The seal on a pump at a chemical plant in the east of England was burning out on average every two weeks due to dry running, resulting in some four hours of downtime each time it failed.

Major savings follow installation of AESSEAL product

A petrochemical company based in the Middle East was having problems with persistent and costly seal failures.

LabTecta FS the answer for gearbox problem

Upgrade solves contamination problem

Leakage problem solved with STS

DMSF seal the answer for US company

AESSEAL seals the deal

STS steam seal updates UK Ethylene plant

AESSEAL lowers the temperature in Montana

AESSEAL system eliminates danger of hydrogen sulfide release

AESSEAL system aids clean-up at US feed mill

LabTecta saving time and money at US plant

Mining company saves $8 million AUD with AESSEAL system

Full steam ahead for refinery after change to STS seals

AESSEAL helps significantly reduce downtime

Improved reliability for new process

Seal upgrade improves reliability and saves over US$81k

Reliability upgrade reduces water consumption

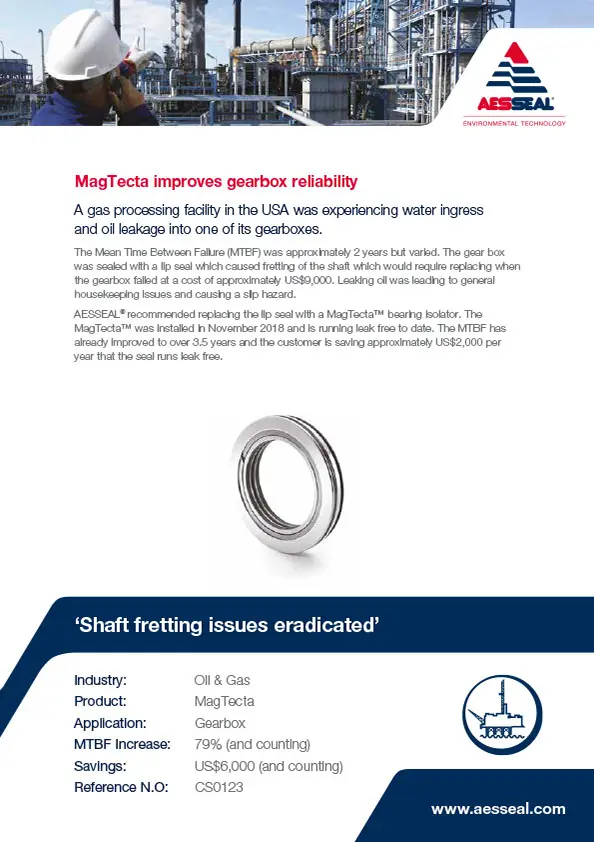

MagTecta improves gearbox reliability

Seal upgrade improves pump availability

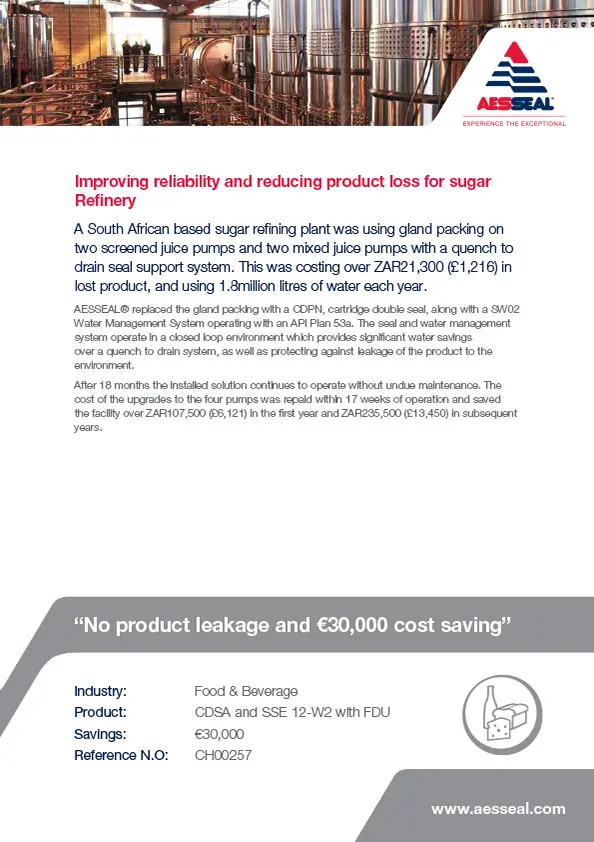

Improving reliability and reducing product loss for sugar Refinery

Lip seal upgrade for US petrochemical plant

AES-Elast™ successfully replaces leading brand

FDA compliant elastomer increases reliability

Cleaner plant with AESSEAL gland packing

Eliminating over 61 million gallons of water from 26 evaporator pumps

Reliability problems solved at mill

LabTecta seals halt costly oil leaks

LabTecta reduces quality issues and improves reliability

MagTecta eliminates gearbox oil leakage

New orders follow success of AESSEAL installation

AESSEAL SW system solves water pressure problem

The AESSEAL DMSF helps cut water usage for US company

A place of greater safety with AESSEAL SCMS

Reliability upgrade saves $24k per year

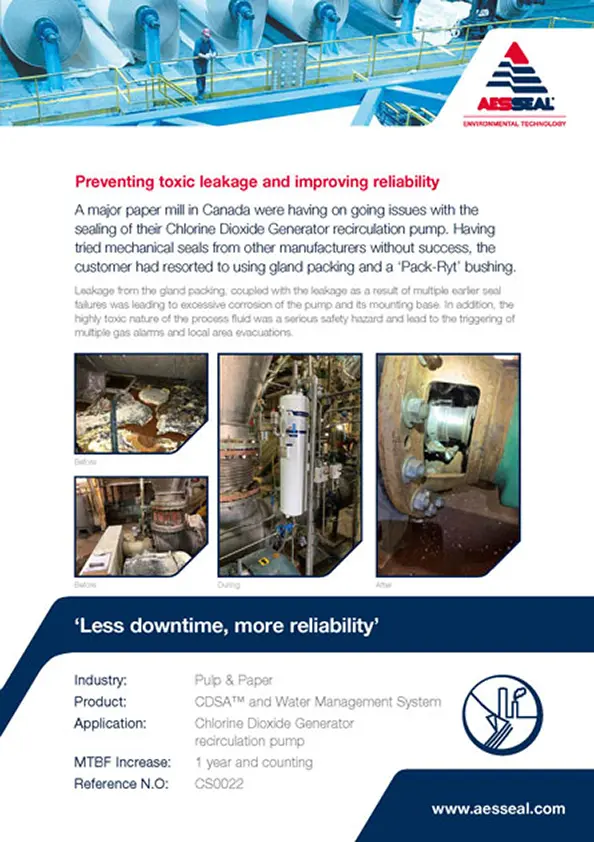

Preventing toxic leakage and improving reliability

ZAR84,000 Saving with reliability upgrade from packing

Reliability upgrade improves reliability 700%

Reliability upgrade improves MTBF 2900%

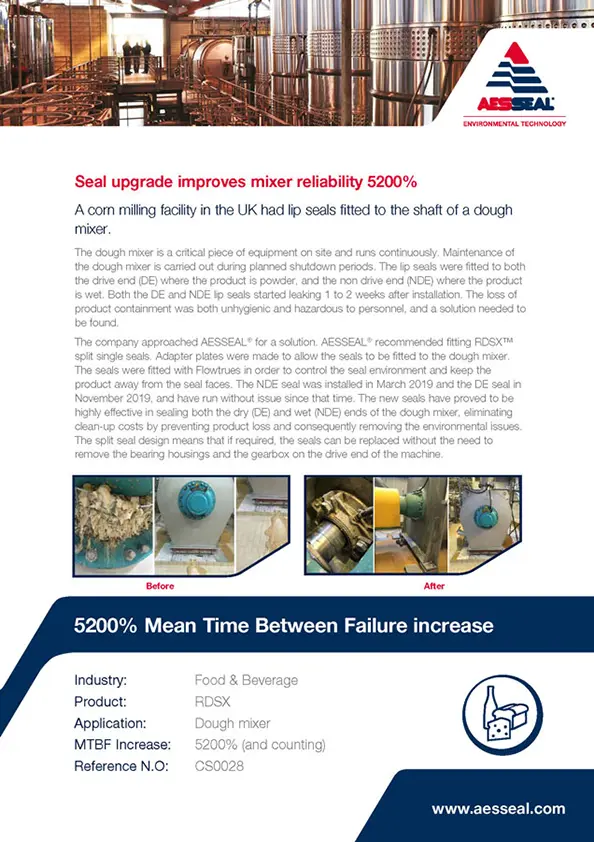

Seal upgrade improves mixer reliability 5200%

Reliability Improved For Waste Energy Company

Gas seal gives 14 years trouble free operation

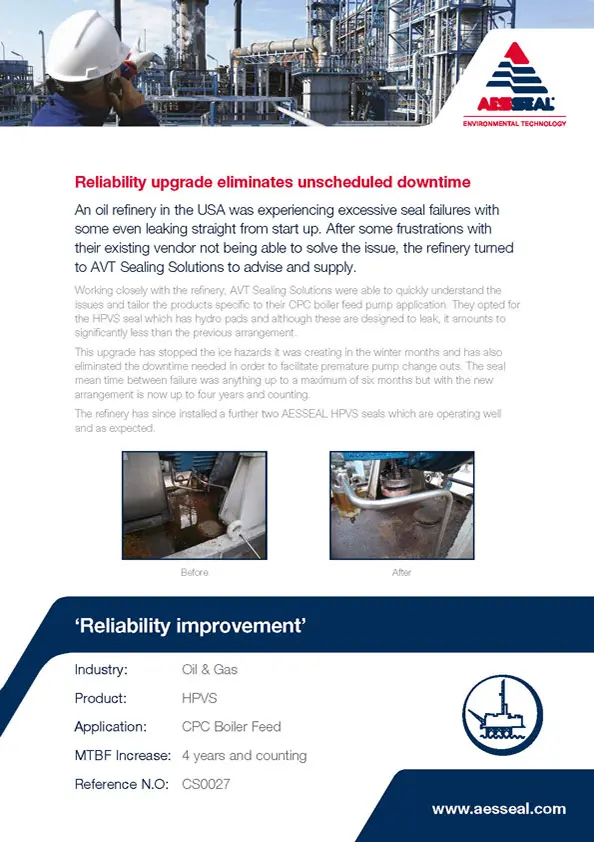

Reliability upgrade eliminates unscheduled downtime

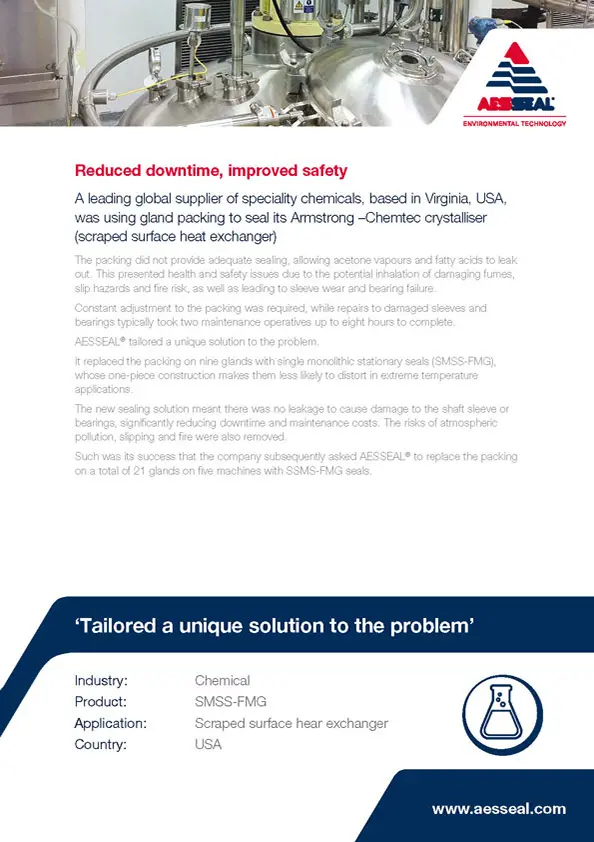

Reduced downtime, improved safety

Specialist paper producer saves almost 6.4 million litres of water per year

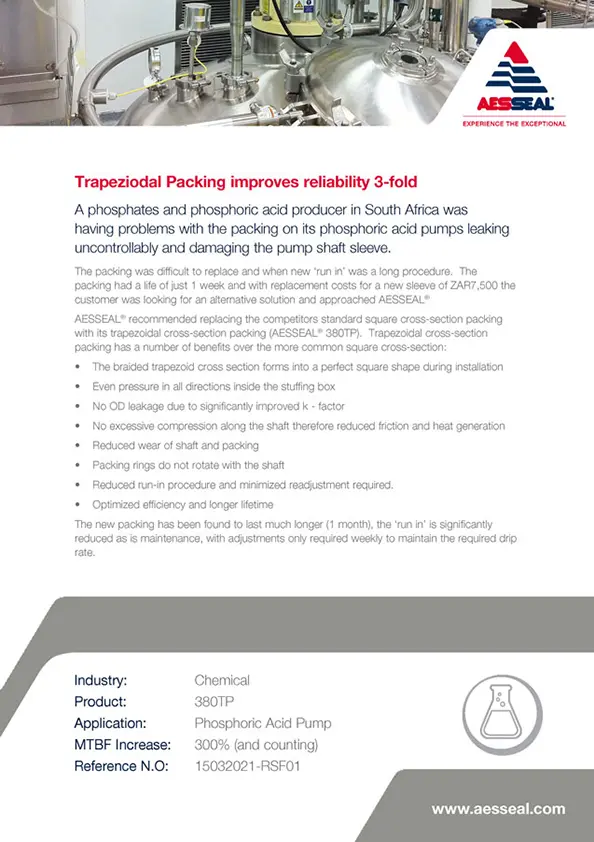

Trapeziodal Packing improves reliability 3-fold

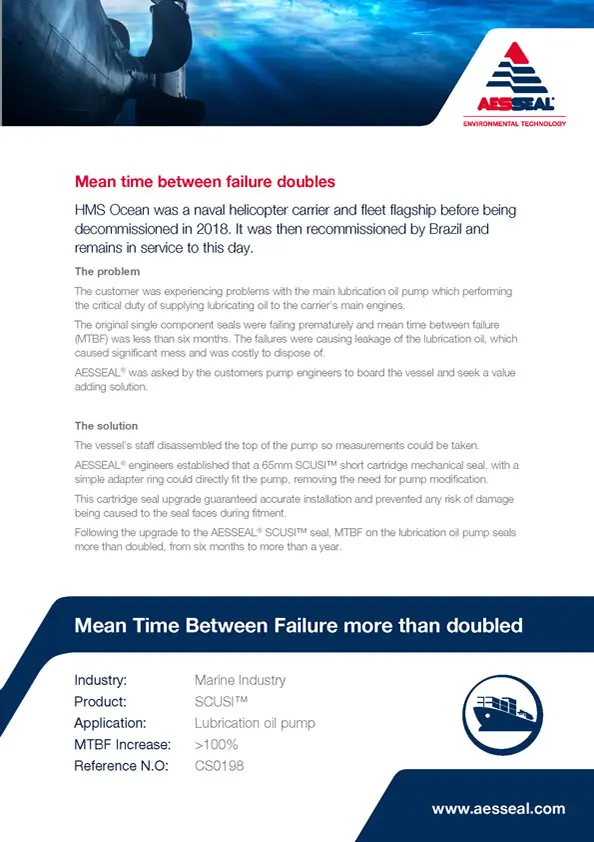

Mean time between failure doubles

Tailored seal solution cuts costs and operational downtime

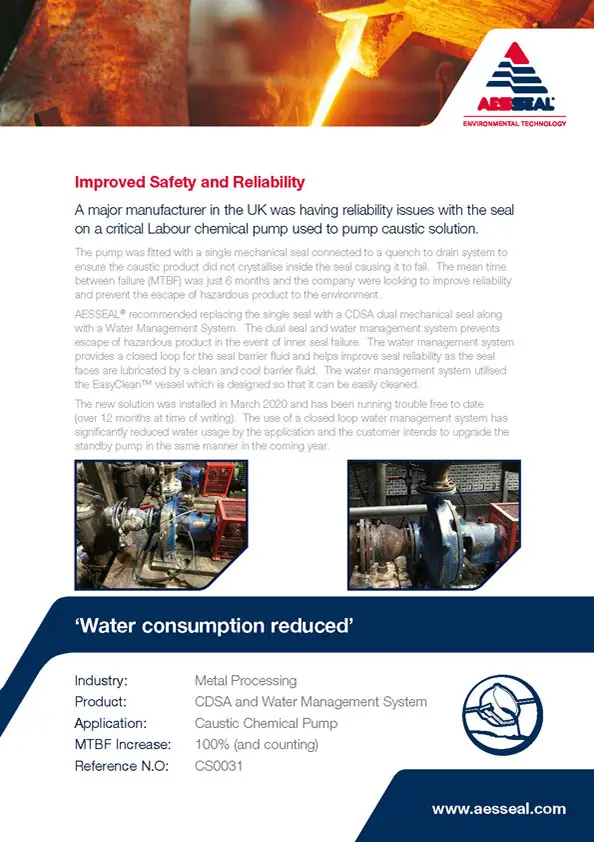

Improved Safety and Reliability

Successful Support System Upgrade Improves Plant Reliability

Unique solution saves $287,000 a year and improves safety

MTBF increases by 233%

Reduced downtime and health & safety benefits

Catalogue of issues lead to failures on power station valves

Improved safety and production efficiency while reducing water consumption

Zinc Smelting Plant Saves Thousands

Eliminating unplanned maintenance with API Plan 32

Huge cost savings and improved reliability with gland packing upgrade

Improving reliability, increasing efficiency

LabTecta ends dust pollution problem for SA firm

Preventing dust from escaping into the working environment and is saving thousands of dollars a year

£137,830 saving & a 1100% MTBF increase

Replacing gland packing reduces cost, and improves reliability

£66,000 savings after upgrading gland packing to an RDS split seal

Replacing lip seals reduces cost, improves reliability and saves the environment

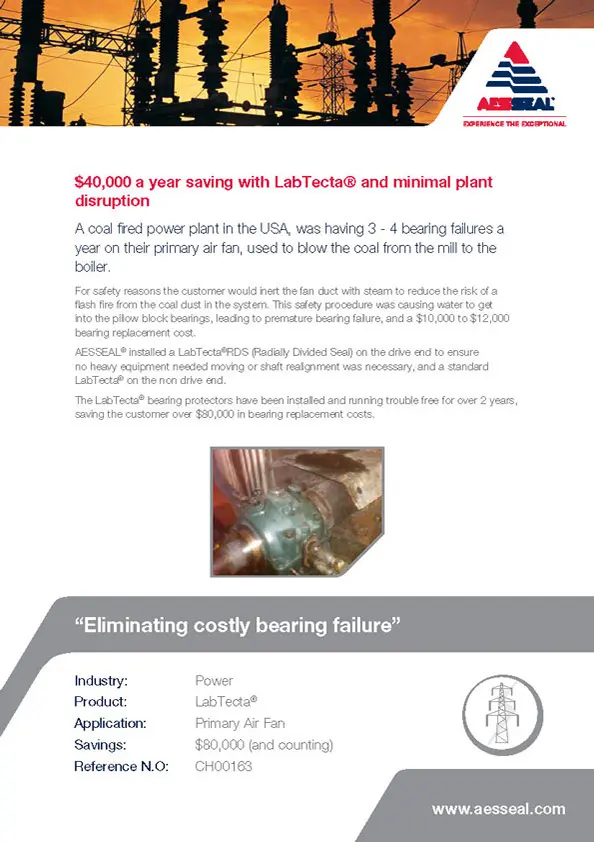

$40,000 a year saving with LabTecta

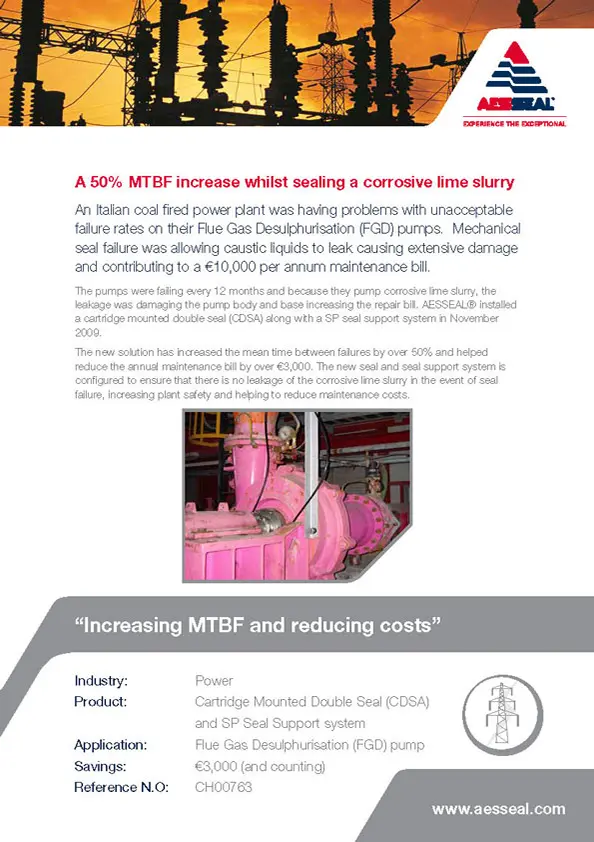

A 50% MTBF increase whilst sealing a corrosive lime slurry

Upgrade eliminates environmental impact and delivers a 833% MTBF improvement

Mechanical seals upgrade reduces maintenance and will save £5,450 per annum

A $30,000 yearly saving for Australian copper mine

$10,500 yearly cost saving for Chemical manufacturer